You just invested in stunning new rims, but now your car shakes like a wet dog at highway speeds. This frustrating problem leaves you questioning your purchase decision and wondering if you received defective wheels.

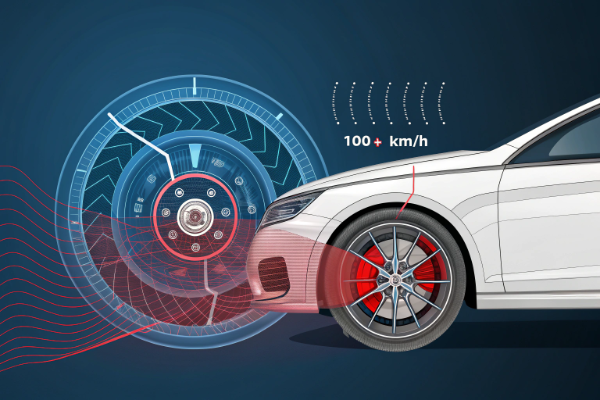

The most common reason new rims cause car vibration at high speeds is improper wheel balancing after tire mounting. Even perfectly manufactured wheels can vibrate if the complete wheel-tire assembly isn't correctly balanced, especially when driving over 100km/h where minor imbalances become noticeable.

I've dealt with hundreds of customers facing this exact issue. As the founder of TreeWheels, a premium forged wheel manufacturer, I can assure you that vibration problems rarely stem from manufacturing defects in the wheels themselves. Let me walk you through the real culprits behind that annoying highway shake and how to resolve it.

Why Does My Car Vibrate When I Reach 100km/h?

You're cruising smoothly until you hit highway speeds, then suddenly your steering wheel feels like it's connected to a jackhammer. This speed-specific vibration points to a particular set of problems that frustrate drivers worldwide.

Car vibration that occurs specifically around 100km/h typically indicates wheel balance issues. At this speed, even minor imbalances create noticeable vibrations as centrifugal forces amplify the problem. The solution usually requires professional dynamic balancing with specialized equipment that can detect subtle imbalances.

Wheel balance issues manifest differently depending on your speed. Below 80km/h, you might not feel anything unusual. But as you approach and exceed 100km/h, physics takes over. The faster your wheels spin, the more any imbalance gets multiplied by centrifugal force.

I've observed this countless times in our testing facility. At TreeWheels, we perform high-speed dynamic balancing on all our forged wheels before they leave our factory. Our quality control process includes rigorous inspections and multiple tests to ensure perfect balance. However, once tires are mounted on these wheels at your local shop, that carefully calibrated balance can be disrupted.

Many tire shops use basic balancing equipment that only measures static balance at lower speeds. This equipment often misses subtle imbalances that become problematic at highway speeds. Road force balancing, which simulates actual driving conditions, is far more effective for detecting these issues.

I recently worked with a customer whose Mercedes S-Class vibrated severely above 110km/h despite having our premium forged wheels. After investigation, we discovered their tire shop had balanced the wheels without using proper centering cones. This created a subtle misalignment that wasn't noticeable at city speeds but became unbearable on the highway. Once properly balanced with the correct equipment, the problem disappeared completely.

| Factor | Impact | Solution |

|---|---|---|

| Balancing equipment quality | Outdated equipment misses subtle imbalances | Use shops with road force balancing technology |

| Centering accuracy | Improper mounting on balancer | Ensure proper hub-centric mounting during balancing |

| Weight distribution | Uneven placement of balance weights | Require precision placement using modern equipment |

| Balancing speed | Many shops balance at low speeds only | Request high-speed balancing (100km/h equivalent) |

Why Is My Car Shaking After New Rims?

You invested in beautiful new wheels, but now your smooth ride feels more like an off-road adventure. This unexpected change has you questioning your purchase and wondering if you received defective products.

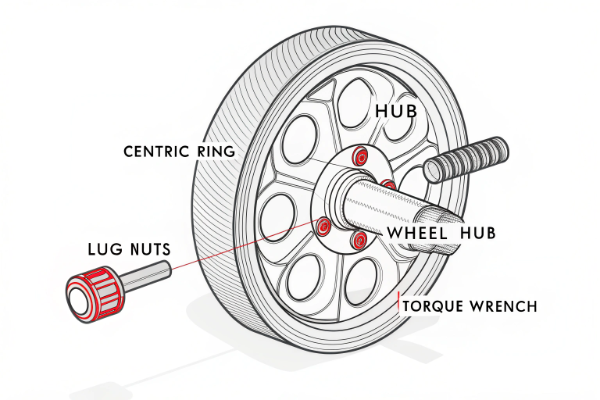

Car shaking after installing new rims often results from installation errors rather than wheel defects. Common issues include improper torque application, missing hub-centric rings, or incompatible wheel specifications for your vehicle. Proper professional installation with attention to these details typically resolves these problems.

Installation errors account for approximately 80% of all vibration complaints we receive at TreeWheels. As a manufacturer committed to quality, I can confidently say that our wheels undergo extensive testing before leaving our facility. Every wheel is inspected for perfect roundness, weight distribution, and structural integrity. We simply don't ship defective products to our customers.

One critical factor many overlook is torque application. When wheel lugs are tightened unevenly or without following proper torque specifications, the wheel sits slightly off-center. This creates a wobble that intensifies with speed. Always ensure your installer uses a calibrated torque wrench and follows the correct tightening sequence.

Hub-centricity is another vital consideration. Modern wheels must center perfectly on your vehicle's hub to prevent vibration. Many aftermarket wheels require hub-centric rings to ensure proper fitment. Without these rings, the wheel centers on the lug nuts instead of the hub, creating inevitable vibration at speed. At TreeWheels, we provide detailed specifications and include hub rings when necessary, but improper installation can still occur.

I've also noticed a clear pattern among customers experiencing vibration issues: many have upgraded to larger diameter wheels than their original equipment. For example, moving from 21-inch factory wheels to 22-inch aftermarket wheels significantly affects ride quality. Larger wheels typically use lower-profile tires with thinner sidewalls, providing less cushioning against road imperfections. This reduced shock absorption makes the vehicle more sensitive to balance and alignment issues.

| Common Installation Errors | Impact | Prevention |

|---|---|---|

| Incorrect torque application | Uneven wheel seating | Use torque wrench and follow sequence |

| Missing hub-centric rings | Wheel centering on lugs instead of hub | Ensure proper ring installation |

| Contamination on mounting surfaces | Uneven seating | Clean all contact surfaces thoroughly |

| Failure to retorque after break-in | Loosening causing vibration | Retighten to specs after 50-100km |

| Incorrect lug nuts or bolts | Improper seating or thread damage | Use only manufacturer-specified hardware |

What Can Cause A Car To Vibrate At High Speed?

You're enjoying your drive until you hit highway speeds, when your car transforms into a vibrating nightmare. This problem extends beyond just wheel issues, encompassing several vehicle systems that could be the real culprits.

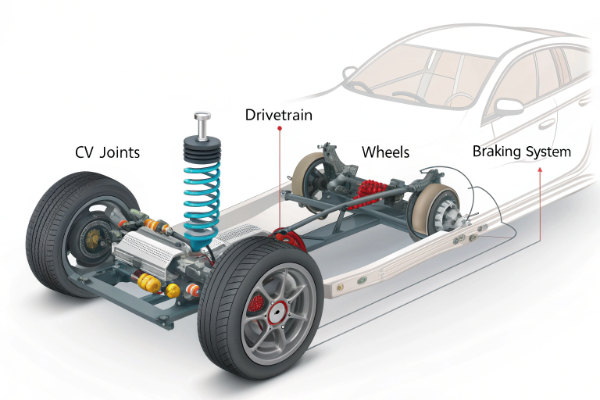

Multiple factors can cause high-speed car vibration including tire issues (uneven wear, separated belts), mechanical problems (worn CV joints, driveshafts, bearings), suspension issues (worn bushings, bad shocks), and brake components (warped rotors). Comprehensive diagnosis is essential as new wheels often reveal pre-existing problems.

While wheel and tire issues are common culprits, vibration at high speeds can stem from numerous vehicle components. As someone who has worked with high-performance wheels for years, I've seen many cases where new wheels were blamed for revealing problems that already existed.

Tire-related issues extend beyond balance problems. Internal belt separation, where the steel belts inside the tire begin to delaminate, creates uneven weight distribution that no amount of balancing can fix. This problem worsens at high speeds and typically requires tire replacement. Similarly, tires with irregular wear patterns will create vibration even when mounted on perfectly manufactured wheels.

Driveline components frequently cause vibrations that mimic wheel balance issues. Worn CV joints, damaged driveshafts, and failing wheel bearings all create vibrations that intensify with speed. In my experience, customers often don't realize these underlying problems until they install new wheels, which typically have tighter tolerances than factory wheels.

Suspension components affect how your vehicle handles road imperfections and can contribute to vibration. Worn control arm bushings, ball joints, or shock absorbers compromise your vehicle's ability to maintain consistent road contact. New wheels, especially larger ones with lower-profile tires, provide less cushioning and make these problems more noticeable.

I recall assisting a customer who insisted our forged wheels were causing severe vibration in his BMW M5. After extensive troubleshooting, we discovered that his vehicle had slightly bent control arms from a previous minor accident. The factory wheels masked this issue due to their flexibility, but our more precise forged wheels highlighted the underlying problem.

| Component | Symptoms | Diagnostic Method |

|---|---|---|

| Tires | Vibration changes with speed | Visual inspection, road force testing |

| Wheel bearings | Noise accompanies vibration | Jack test, stethoscope examination |

| CV joints | Vibration during acceleration | Inspection for torn boots, clicking sounds |

| Driveshaft | Vibration increases with speed | Inspection for runout, balance check |

| Suspension | Vibration over bumps | Inspection for worn components |

| Brake rotors | Vibration during braking | Thickness variation measurement |

Can Tires Be Balanced But Still Vibrating?

You've had your tires professionally balanced, yet that annoying vibration persists. This puzzling situation leaves you wondering if you've wasted money on balancing or if something more serious is wrong.

Yes, tires can be perfectly balanced yet still cause vibration due to issues like tire conicity (slight cone shape), internal structural damage, radial or lateral runout problems, or force variation. Standard balancing equipment often misses these issues, which require specialized road force balancing to detect.

Standard wheel balancing only addresses weight distribution around the wheel's circumference. However, modern tires can have complex internal issues that create vibration even when perfectly balanced. This is why at TreeWheels, we recommend comprehensive road force balancing for all our wheels after tire mounting.

Tire conicity occurs when a tire takes a subtle cone shape rather than a perfect cylinder. This creates a constant pull and vibration that intensifies with speed. Similarly, radial force variation means the tire doesn't maintain consistent stiffness throughout its rotation, creating a bounce effect that traditional balancing can't detect.

Even the most precisely manufactured wheels from our facility can exhibit vibration if paired with problematic tires. I've seen cases where customers blamed premium forged wheels for vibration, only to discover their tires had internal defects. When mounting new tires on quality wheels, always insist on road force balancing that measures these variations.

The most overlooked aspect of proper wheel/tire setup is the matching process. Advanced tire shops use road force balancing machines not just to add weights but to determine the optimal position for mounting the tire on the wheel. By aligning the stiffest point of the tire with the lowest point of the wheel, vibration can be minimized beyond what simple balancing achieves.

In our manufacturing process at TreeWheels, we conduct runout testing that measures lateral and radial runout to within 0.015mm. This precision ensures our wheels maintain perfect roundness. However, when a tire with even minor defects is mounted, this precision can be compromised. This is why comprehensive testing of the complete wheel-tire assembly is crucial.

I recently consulted on a case where a customer with a high-performance Porsche was experiencing vibration despite multiple balancing attempts. By employing road force balancing and finding the optimal mounting position, we reduced the measured force variation from 28 pounds to just 7 pounds, completely eliminating the perceptible vibration.

| Beyond Basic Balancing | What It Addresses | Why It Matters |

|---|---|---|

| Road force measurement | Stiffness variations | Detects issues standard balancing misses |

| Match-mounting | Aligns tire/wheel high-low spots | Minimizes combined runout |

| Dynamic balance | Tests at multiple speeds | Ensures balance at highway speeds |

| Runout measurements | Detects wheel or tire roundness issues | Identifies manufacturing defects |

| Hub-centric mounting | Ensures proper wheel centering | Prevents vibration from off-center rotation |

Conclusion

High-speed vibration after installing new rims typically stems from improper balancing, installation errors, or reveals pre-existing vehicle issues rather than wheel manufacturing defects. Proper professional installation with comprehensive road force balancing solves most problems. At TreeWheels, we ensure every forged wheel meets rigorous quality standards to deliver the smooth, precise performance your premium vehicle deserves.