Finding high-quality forged wheels feels overwhelming with countless options and price ranges. Many buyers struggle to determine which manufacturers truly deliver premium products versus those making empty promises.

The best places to buy high-quality forged wheels are directly from reputable manufacturers like Tree Wheels or established distributors who source from certified factories in China. Look for suppliers who offer proper certifications, FEA testing reports, and use raw forgings from respected foundries.

As a manufacturer in this industry for years, I've seen many buyers struggle with counterfeit or subpar products. The truth is that many well-known wheel brands actually source their products from Chinese factories like ours – they just don't advertise this fact openly. Let me share some insider knowledge to help you find genuine high-quality forged wheels.

Who makes the best forged wheels?

Many wheel enthusiasts feel lost when trying to identify truly superior forged wheel manufacturers among countless brands making bold claims about quality and performance.

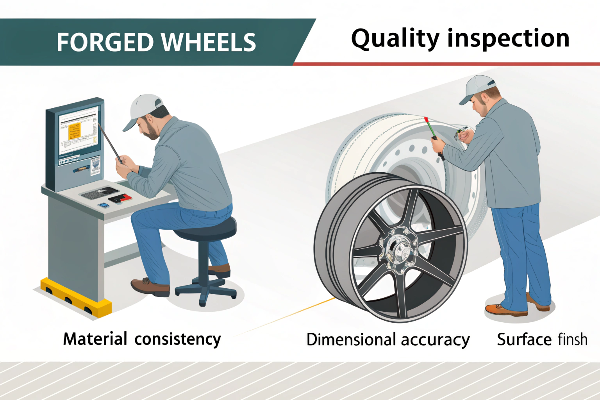

The best forged wheels come from manufacturers who use premium aluminum alloys, maintain strict quality control processes, and employ advanced forging techniques. Top producers include specialized factories in China that supply many global brands, particularly those using premium forgings from foundries like Zhejiang Hongxin, Shandong Juncheng, and Jiangsu Poran.

At Tree Wheels, we've built our reputation on creating superior forged wheels through careful material selection and rigorous production standards. When evaluating wheel quality, understanding the manufacturing process is crucial. The journey begins with selecting the right aluminum billets, typically 6061-T6 or 7075-T6 alloys for optimal strength-to-weight ratio.

Our manufacturing process employs both cold and hot forging techniques under massive hydraulic presses (up to 9,000 tons of pressure) to align the metal's grain structure for superior strength. This contrasts sharply with cast wheels, where molten aluminum is simply poured into molds, resulting in random grain structures and potential air pockets.

Key Quality Indicators for Premium Forged Wheels

| Quality Factor | What to Look For | Why It Matters |

|---|---|---|

| Raw Material Source | Certified aluminum alloy suppliers | Determines fundamental strength properties |

| Forging Process | Multiple-stage forging with proper heat treatment | Creates optimal grain structure and eliminates weaknesses |

| Testing Protocols | FEA testing, impact testing, radial fatigue testing | Verifies wheel can handle real-world stresses |

| Surface Treatment | Multiple layers of protection, quality paint/powder coating | Prevents corrosion and ensures longevity |

| Certifications | ISO, DOT, TÜV standards compliance | Confirms adherence to international safety standards |

What are the most reliable replica wheels?

Car enthusiasts worry about safety risks and poor quality when considering replica wheels, but don't want to pay astronomical prices for name-brand options.

The most reliable replica wheels are those produced by legitimate manufacturers who focus on proper engineering rather than merely copying designs. Quality replicas undergo the same rigorous testing as original wheels, use similar material quality, and maintain proper weight ratings – typically costing 30-50% less than brand-name counterparts.

](https://treewheels.com/wp-content/uploads/2025/08/image-3-various-replica-wheel-designs-manufacture.png)

Many don't realize that the term "replica" doesn't automatically mean inferior quality. At Tree Wheels, we differentiate between properly engineered performance replicas and dangerous counterfeits. True quality replicas maintain critical safety and performance specifications while offering design similarities to popular styles.

When sourcing reliable replica wheels, I always recommend looking beyond visual appearance. A proper replica must maintain the original's load ratings, undergo similar testing protocols, and use comparable materials. Our engineering team thoroughly analyzes original wheel designs before creating replicas that maintain or exceed safety margins while offering significant cost advantages.

Understanding Different Types of Wheel Construction

Quality replica wheels come in various construction methods, each with specific benefits:

| Construction Type | Manufacturing Process | Best For | Price Range |

|---|---|---|---|

| Monoblock Forged | Single piece forged from aluminum billet | Maximum strength, racing applications | $170-$370 |

| 2-Piece Forged | Forged center with separate outer barrel | Custom widths, aggressive fitments | $395-$570 |

| 3-Piece Forged | Separate forged center with two-piece rim | Ultimate customization, show cars | $480-$680 |

| Flow-Formed | Cast center with flow-formed barrel | Budget-conscious enthusiasts | $120-$250 |

Many of our customers find that properly engineered 2-piece and 3-piece replica wheels offer the best balance of performance, customization options, and value. These construction methods allow us to create wheels that precisely match vehicle specifications while maintaining proper load ratings.

Which company makes the best wheels?

Wheel buyers face decision paralysis with hundreds of brands claiming superior quality, making it nearly impossible to identify truly exceptional manufacturers from clever marketers.

The best wheel companies maintain complete control over their production process, source premium raw materials, employ advanced engineering teams, and validate designs through comprehensive testing. Superior manufacturers include specialized factories that supply OEM clients and high-end aftermarket brands, particularly those with full ISO certification.

From my experience managing a wheel manufacturing facility, I can tell you that the best wheel companies aren't necessarily those with the biggest marketing budgets. True quality comes from technical expertise and manufacturing discipline. Many top-tier wheel brands actually source from a small network of specialized factories with exceptional capabilities.

At Tree Wheels, we've invested heavily in state-of-the-art CNC machinery, precision measuring equipment, and skilled engineers. Our facility maintains tight tolerances throughout production – typically within 0.02mm for critical dimensions. This level of precision ensures perfect balance and fitment, which directly impacts vehicle performance and safety.

Key Capabilities of Top-Tier Wheel Manufacturers

| Manufacturing Capability | Industry Standard | Premium Manufacturers |

|---|---|---|

| CNC Machining Precision | ±0.05mm | ±0.02mm |

| Surface Treatment Layers | 3-4 layers | 5-7 layers with specialized primers |

| Quality Control Inspection | Spot-checking | 100% inspection with computerized balancing |

| Design Customization | Limited options | Full customization with engineering support |

| Testing Protocols | Basic load testing | Comprehensive multi-stage testing including corner fatigue |

When evaluating wheel manufacturers, ask specific questions about their quality control processes. Premium manufacturers will gladly provide detailed information about their testing protocols, raw material sources, and engineering capabilities. This transparency is often the best indicator of a truly superior wheel company.

How much are forged wheels?

Many enthusiasts assume that quality forged wheels are financially out of reach, forcing them to compromise on safety and performance with cheaper alternatives.

Genuine forged wheels from direct manufacturers typically range from $170-$370 per wheel for one-piece designs, $395-$570 for two-piece constructions, and $480-$680 for three-piece wheels, with variations based on size, complexity, and finishing options. Custom finishes and special designs may increase costs by 10-30%.

Through our years of producing forged wheels, I've found that pricing transparency builds trust with customers. Many wheel buyers are surprised to learn that dealing directly with a manufacturer like Tree Wheels can reduce costs by 40-60% compared to purchasing through multiple distribution layers.

Our pricing structure is straightforward – one-piece monoblock wheels start around $170 for 15"-17" sizes and increase to approximately $370 for 24" applications. Two-piece and three-piece constructions cost more due to their complex manufacturing processes and additional materials. For instance, our three-piece 24" wheels are priced at $680 per wheel.

Understanding Pricing Factors for Forged Wheels

| Factor | Impact on Price | Typical Cost Increase |

|---|---|---|

| Wheel Size | Larger sizes require more raw material | +$30-50 per inch increase |

| Construction Type | More complex designs require additional labor | +$200-300 from one-piece to three-piece |

| Concavity Profile | Deep concave designs require more machining | +$40-80 for aggressive concavity |

| Custom Finishes | Special coatings and multi-tone finishes require additional labor | +$50-150 depending on complexity |

| Custom Offsets | Non-standard specifications require program adjustments | +$30-60 for special offsets |

I always recommend customers focus on their specific performance needs rather than simply choosing the most expensive option. For street performance and occasional track use, our one-piece forged wheels offer exceptional value. For show vehicles requiring unique aesthetics, our three-piece options allow limitless customization while maintaining safety standards.

Conclusion

Finding high-quality forged wheels requires understanding manufacturing processes, asking the right questions, and working directly with reputable manufacturers. By prioritizing quality materials, proper testing, and transparent business practices, you'll secure superior wheels at fair prices. Tree Wheels delivers premium forged wheels with sincerity above all, ensuring your investment enhances both performance and aesthetics.