Choosing the right forged wheels for your vehicle can feel overwhelming. With different construction types offering various benefits, how do you know which option is best for your specific automotive needs?

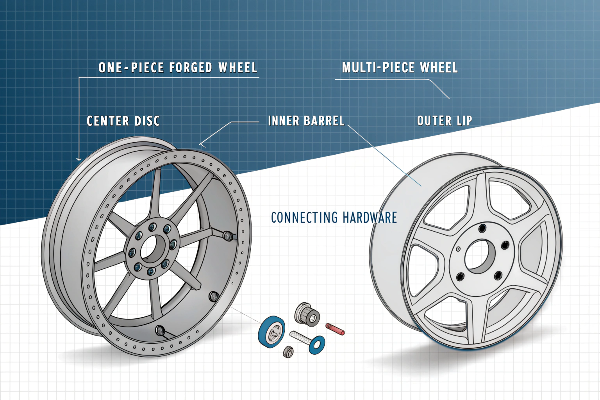

The main difference between one-piece and multi-piece forged wheels lies in their construction. One-piece wheels are manufactured as a single unit, while multi-piece wheels are assembled from separate components - typically a center disc plus one or more rim sections connected with hardware.

As a manufacturer with years of experience crafting premium forged wheels, I've guided countless clients through this decision. The choice between single-piece and multi-piece construction affects everything from performance to aesthetics. Let's explore the key differences to help you make an informed decision for your next wheel upgrade.

What is the difference between single piece and multi piece wheels?

Customers often ask about construction differences when considering an upgrade. Is one type truly superior, or does it depend on specific applications?

Single-piece wheels are forged from one continuous block of aluminum, creating a unified structure without joints. Multi-piece wheels combine separate components - typically a center disc and outer rim(s) - joined with precision bolts, allowing for customization in size, offset, and appearance.

When we manufacture wheels at Tree Wheels, we distinguish them based on their overall structure. One-piece forged wheels represent a single continuous unit, machined from a solid block of aluminum through our advanced forging process. In contrast, multi-piece wheels consist of separate components assembled together.

Two-piece wheels typically combine a center disc with a rim section (often called the "barrel"). Three-piece wheels take this modular approach further, usually incorporating a center disc plus two rim sections that create the complete barrel. This structural difference fundamentally impacts not just how we manufacture the wheels, but also their performance characteristics and aesthetic possibilities.

From a production perspective, manufacturing a one-piece wheel requires more sophisticated equipment for the initial forging but fewer assembly steps. Our multi-piece offerings require precise engineering to ensure the connection points maintain structural integrity under demanding conditions. We've found that certain high-performance applications benefit from the unified strength of monoblock (one-piece) construction, while custom automotive projects often benefit from the design flexibility of multi-piece wheels.

Comparative Strength and Weight Characteristics

| Wheel Type | Strength | Weight | Manufacturing Complexity |

|---|---|---|---|

| One-Piece | Highest | Lowest | Single continuous process |

| Two-Piece | High | Medium | Requires precision assembly |

| Three-Piece | Good | Highest | Most complex assembly process |

What is the point of multi piece wheels?

When customers visit our factory, they often wonder why we offer multi-piece options when one-piece seems simpler. What benefits justify their more complex design?

Multi-piece wheels excel in customization flexibility, allowing for unique fitments impossible with one-piece designs. They enable extreme lip depths, custom widths, and easy repair of damaged sections without replacing the entire wheel - perfect for modified vehicles requiring specific dimensions.

showcasing deep lip design](https://treewheels.com/wp-content/uploads/2025/08/image-3-custom-multi-piece-wheels-showcasing-deep.png)

The primary advantage of multi-piece wheels lies in their unparalleled design flexibility. When I work with performance shops modifying Mustangs and other high-end vehicles, they often request specialized fitments that one-piece wheels simply cannot achieve. Three-piece wheels are particularly valuable when clients need ultra-wide or exceptionally narrow widths, or when they desire dramatically deep lips for a striking visual impact.

In our manufacturing facility, we've produced three-piece wheels with extraordinary lip depths that would be physically impossible to create from a single forging. The sectional construction allows us to precisely engineer each component for its specific function. This modularity also provides practical benefits, as damaged sections can be replaced individually rather than requiring an entirely new wheel.

Beyond fitment considerations, multi-piece wheels offer significant aesthetic advantages. The visible hardware joining the components becomes part of the design language, with the bolts serving as both functional elements and visual accents. We can create two-tone or multi-color finishes by treating each section differently, offering customization options not possible with monoblock wheels.

For automotive enthusiasts seeking the ultimate in personalization, multi-piece wheels enable "mix and match" combinations of different center designs with various lip styles. This gives modification shops tremendous flexibility in creating truly unique wheel packages for their clients. Many of our international customers appreciate this versatility when creating show-stopping vehicles that stand out from the crowd.

Common Multi-Piece Wheel Applications

| Vehicle Type | Typical Wheel Choice | Primary Reason |

|---|---|---|

| Track/Racing | One-piece | Maximum strength-to-weight ratio |

| Show Cars | Three-piece | Dramatic aesthetic options |

| Modified Muscle Cars | Two/Three-piece | Custom fitment for wide tires |

| Luxury Custom Builds | Three-piece | Premium appearance with deep lips |

Are 2-piece wheels better than 1 piece?

I frequently get asked by modification shops if they should recommend two-piece wheels over one-piece designs. The answer isn't always straightforward.

Two-piece wheels aren't inherently "better" than one-piece designs - they serve different purposes. One-piece wheels offer superior strength-to-weight ratios and durability under extreme conditions. Two-piece wheels provide greater design flexibility, repair options, and aesthetic possibilities while maintaining good performance characteristics.

When advising our clients about wheel selection, I recommend a simple hierarchy: one-piece first, two-piece second, three-piece third - unless specific design requirements dictate otherwise. This recommendation comes from years of manufacturing experience and understanding of structural engineering principles.

One-piece forged wheels provide unmatched strength and stability because they lack connection points that could potentially fail under stress. The unified structure of a monoblock wheel means force is distributed evenly throughout the entire wheel. When we test wheels on our lab equipment, one-piece designs consistently demonstrate superior durability under extreme conditions.

However, two-piece wheels offer a compelling middle ground for many applications. They provide significantly more design flexibility than one-piece options while avoiding some of the weight penalties of three-piece configurations. For clients seeking moderate lip depth or specific offset requirements that one-piece wheels can't accommodate, two-piece designs deliver an excellent balance of performance and aesthetics.

Price considerations also factor into this decision. Looking at our current catalog, one-piece 19" wheels start around $210 per unit, while two-piece versions begin at $430. This substantial difference reflects both the more complex manufacturing process and the enhanced customization options available with multi-piece designs.

Many of our custom shop clients have found that two-piece wheels represent an ideal compromise for street performance vehicles, where the slight weight increase and minimal structural differences have negligible real-world impact, but the design benefits are immediately noticeable.

Application-Based Wheel Selection Guide

| Primary Need | Recommended Construction | Why |

|---|---|---|

| Maximum Performance | One-piece | Best strength-to-weight ratio |

| Moderate Customization | Two-piece | Good balance of strength and design options |

| Extreme Styling | Three-piece | Maximum customization potential |

| Cost Efficiency | One-piece | Simpler manufacturing process |

What are the disadvantages of forged wheels?

Despite all the benefits, some customers hesitate when they see the price difference between forged and cast wheels. Is the premium price justified?

Forged wheels' main disadvantages include higher cost due to intensive manufacturing processes and limited design flexibility in one-piece versions. Multi-piece forged wheels address design limitations but increase complexity, weight, and cost compared to simpler alternatives.

While forged wheels offer significant performance advantages, they do come with certain trade-offs that buyers should consider. The most obvious disadvantage is price - our forged wheels typically cost substantially more than cast alternatives. This price difference reflects the intensive manufacturing process required to create properly forged wheels. For example, our one-piece 20" forged wheels start at $225, while comparable cast wheels might be half that price.

The forging process itself creates some limitations, particularly for one-piece designs. Since the metal is compressed under extreme pressure, certain intricate designs that are easily achieved with casting become difficult or impossible with forging. This is one reason why multi-piece options have become popular - they allow us to create complex center designs while maintaining the structural benefits of forged components.

For multi-piece forged wheels, the main disadvantages include increased weight compared to one-piece equivalents. The hardware required to connect the components adds mass, which can impact performance slightly. Three-piece designs, while offering maximum customization, represent our heaviest and most expensive options - our 21" three-piece wheels start at $570, more than double the price of equivalent one-piece designs.

Maintenance considerations also differ between wheel types. One-piece forged wheels require minimal maintenance beyond normal cleaning. Multi-piece designs require occasional inspection and potentially re-torquing of the hardware that connects the components - a minor but additional maintenance requirement that some customers prefer to avoid.

Despite these disadvantages, the demand for our forged wheels continues to grow among performance-focused clients who understand the significant benefits in strength, weight reduction, and durability that properly engineered forged wheels provide over cast alternatives.

Forged Wheel Comparison Table

| Factor | One-Piece Forged | Multi-Piece Forged | Cast Wheels |

|---|---|---|---|

| Relative Cost | High | Very High | Moderate |

| Weight Efficiency | Excellent | Good | Fair |

| Design Flexibility | Limited | Excellent | Very Good |

| Strength | Highest | High | Moderate |

| Maintenance | Minimal | Periodic hardware checks | Minimal |

Conclusion

When selecting between one-piece and multi-piece forged wheels, consider your priorities: performance, aesthetics, or customization. One-piece offers unmatched strength and simplicity, while multi-piece provides design flexibility for unique applications.

At Tree Wheels, we craft all our forged wheel types with precision and care, ensuring sincerity above all in every wheel we produce.