Are you tired of your tires slipping off rims during intense off-road adventures? This frustrating and dangerous situation can ruin your experience and leave you stranded in extreme terrain. Beadlock wheels solve this critical problem.

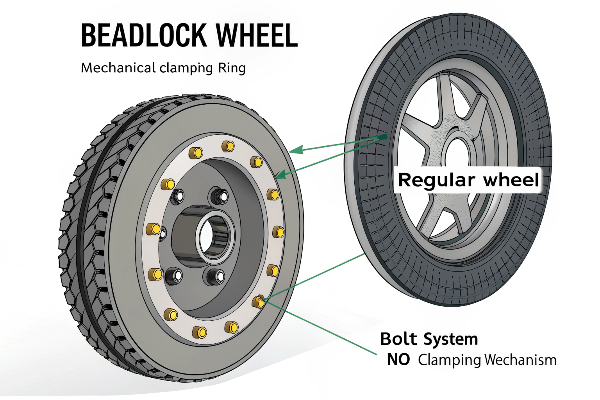

Beadlock wheels are specialized off-road rims with an additional outer ring that mechanically clamps the tire bead to the wheel. This prevents the tire from separating from the rim when running at extremely low pressures required for maximum traction in challenging off-road conditions.

gripping terrain off road beadlock wheels in action](https://treewheels.com/wp-content/uploads/2025/07/1-for-off-road-beadlock-wheels-in-action-a-det.png)

As a manufacturer specializing in high-end forged wheels, I've seen countless customers transform their off-road experience with proper beadlock wheels. The difference is remarkable - especially when tackling sand, mud, rocks or steep inclines where tire pressure becomes a critical factor. Let's dive deeper into what makes these wheels special and clear up some common misconceptions.

What Is The Difference Between Beadlock And Regular Wheels?

Traditional wheels rely solely on air pressure to keep tires mounted securely. When pressure drops too low, the tire bead can slip off the rim, creating dangerous situations and potential damage to both components.

Beadlock wheels feature a mechanical clamping system where an outer ring physically bolts to the wheel, pinching the tire bead in place. This allows for extremely low tire pressure without risk of tire separation, while regular wheels require maintaining higher pressures (typically 30+ PSI) to keep tires mounted.

The structural differences between beadlock and regular wheels go beyond just appearance. Beadlocks are typically forged rather than cast, ensuring maximum strength for extreme conditions. The design incorporates an outer ring with multiple bolts (usually 16-32) that clamp through the tire's bead and into the wheel itself. This creates a mechanical grip that's independent of air pressure.

Installation is also significantly different. Regular wheels allow for straightforward tire mounting, while beadlocks require careful assembly with precise torque specifications for each bolt in a specific sequence. This prevents warping and ensures even pressure distribution. The maintenance requirements also differ substantially - beadlocks need regular bolt checks and retorquing to maintain their integrity, while regular wheels rarely need such attention.

Performance characteristics vary dramatically between these wheel types. When properly installed, beadlocks provide superior traction in challenging terrain by allowing tires to conform to obstacles without rolling off the rim. This "airing down" technique is essential for serious off-roaders but impossible with standard wheels. The trade-off comes in on-road performance, where beadlocks can create vibration and balance issues if not perfectly maintained.

| Feature | Beadlock Wheels | Regular Wheels |

|---|---|---|

| Construction | Usually forged | Cast or forged |

| Minimum Safe Tire Pressure | Significantly reduced | 30+ PSI |

| Mounting Mechanism | Mechanical clamping | Air pressure only |

| Installation Complexity | High (requires specific torque pattern) | Low |

| Maintenance | Regular bolt checks required | Minimal |

| Off-road Performance | Superior at low pressures | Limited by minimum pressure |

| Weight | Heavier | Lighter |

| Cost | Higher | Lower |

Are Beadlocks Good For Off-Roading?

When facing extreme terrain like deep sand or slippery rock faces, standard wheels force a difficult choice: maintain safe tire pressure but sacrifice traction, or risk tire separation by running lower pressures for better grip.

Beadlock wheels are excellent for serious off-roading because they allow you to safely run significantly reduced tire pressures which dramatically increases the tire's footprint, improving traction on sand, mud, and rocks. This capability is essential for tackling extreme terrain that would be impossible with regular wheels.

The performance advantages of beadlock wheels in off-road environments cannot be overstated. When I create custom beadlock wheels for serious off-roaders, I emphasize several key benefits that make them essential equipment rather than optional upgrades.

First, the ability to run at dramatically reduced air pressure transforms how a vehicle interacts with challenging terrain. At lower pressures, tires can conform around obstacles rather than attempting to climb over them. This creates a larger contact patch that distributes weight more effectively, preventing the vehicle from sinking in soft surfaces like sand or mud. The difference can be between completing a trail and getting hopelessly stuck.

Second, beadlocks provide confidence in technical rock-crawling situations where sidewall grip becomes crucial. When navigating steep rock faces, the tire's sidewall often provides critical traction. With beadlocks, drivers can position their vehicles in ways that would otherwise risk tire separation with standard wheels.

Third, the durability factor cannot be ignored. Even the highest quality standard wheels can experience bead failure under the stresses of serious off-roading. I've manufactured both types and witnessed the difference firsthand - properly designed beadlock wheels withstand impacts and lateral forces that would cause immediate failures in conventional setups.

However, beadlocks do come with trade-offs. They're heavier, which affects unsprung weight and can impact overall vehicle performance. They require consistent maintenance and proper installation. And they're a significant investment compared to standard wheels. But for those who regularly tackle challenging terrain, these compromises are well worth the transformative off-road capability they provide.

What Is The Difference Between Real And Fake Beadlock Wheels?

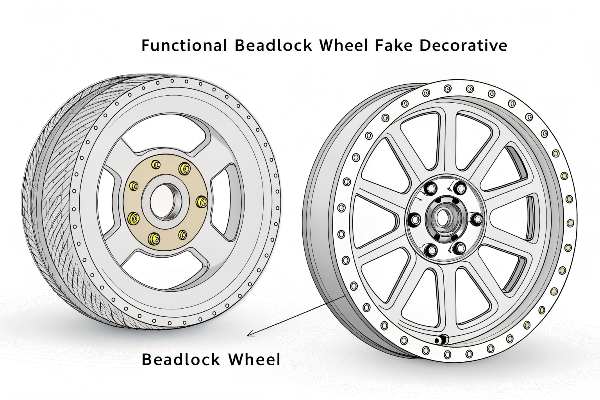

Many wheels advertised as "beadlocks" are merely styled to look the part. These cosmetic imitations can cause dangerous confusion when drivers attempt to run low tire pressures, mistakenly believing their wheels provide actual mechanical retention.

Real beadlock wheels have a functional outer ring physically bolted through the tire bead, mechanically securing it to the wheel. Fake beadlocks (also called "simulated" or "style" beadlocks) only mimic this appearance without providing any mechanical clamping, relying solely on air pressure like regular wheels.

The distinction between real and fake beadlock wheels goes far beyond simple aesthetics and directly impacts both safety and performance. As someone who produces authentic forged beadlock wheels, I encounter frequent confusion about these differences.

Authentic beadlock wheels feature a removable outer ring secured with numerous bolts (typically 16-32) that physically clamp through the tire's outer bead and into the wheel itself. This creates a true mechanical connection that maintains tire position even at significantly reduced pressures. The manufacturing process requires precise machining tolerances and high-strength materials to withstand the extreme forces encountered during off-road use.

Simulated beadlocks, by contrast, incorporate styling elements that mimic the appearance of bolt patterns and rings, but these features are purely decorative. They're often cast directly into the wheel face or attached as non-functional overlays. While they may look convincing, they provide zero mechanical retention of the tire bead. This means they must maintain normal tire pressures to prevent bead separation.

The performance implications are significant. Real beadlocks allow for the "aired down" driving technique essential for maximizing traction in difficult terrain. Fake beadlocks cannot safely run at reduced pressures, negating the primary advantage of beadlock wheels. Additionally, authentic beadlocks typically undergo more rigorous strength testing due to their intended use in extreme conditions.

From a manufacturing perspective, producing real beadlock wheels requires significantly more engineering, material quality, and precision than simulated versions. This explains much of the price difference between authentic and cosmetic beadlocks - one is specialized performance equipment while the other is primarily an aesthetic upgrade.

Is Beadlock Rims Illegal?

The legality of beadlock wheels creates considerable confusion for off-road enthusiasts. Many mistakenly believe these specialized wheels are universally banned, while others assume they're always legal since they're readily available for purchase.

Most true beadlock wheels are not street legal in many jurisdictions because they lack DOT certification, with mechanical clamping systems falling outside standard wheel safety regulations. However, laws vary significantly by location, with some areas allowing their use or having exemptions for off-road-only vehicles.

The legal status of beadlock wheels creates a paradoxical situation that affects both manufacturers and users. As a producer of high-performance forged wheels including beadlock designs, I navigate this complex regulatory landscape daily. The core issue stems from certification requirements rather than the technology itself.

In the United States, most road-legal wheels must meet Department of Transportation (DOT) standards, which primarily assess components secured through conventional means. True beadlocks, with their bolted retention systems, don't fit neatly into these testing protocols. Consequently, many manufacturers (including ourselves) must label authentic beadlocks as "off-road use only" despite their superior performance characteristics.

Ironically, simulated beadlock wheels that provide no actual safety benefit in off-road conditions can obtain full street legality since they're functionally identical to conventional wheels. This creates the counterintuitive situation where wheels that look capable but aren't receive legal approval, while truly functional equipment faces restrictions.

Enforcement practices add another layer of complexity. Some regions strictly prohibit beadlocks on public roads, while others take a more lenient approach, focusing on actual safety issues rather than technical compliance. The distinction between dedicated off-road vehicles (which may never see public roads) and dual-purpose vehicles further complicates matters.

Professional off-roaders and dedicated enthusiasts often maintain two sets of wheels - beadlocks for trail use and conventional wheels for transport to and from off-road areas. Others accept the legal ambiguity as part of the hobby, understanding that the performance benefits in challenging terrain sometimes justify the regulatory gray area. As wheel manufacturers, we focus on creating the highest quality products possible while clearly communicating intended use cases and legal limitations.

Conclusion

Beadlock wheels provide essential mechanical tire retention for serious off-roading at low pressures, but require understanding the differences between real and simulated versions and navigating complex legal considerations. At Tree Wheels, we craft premium forged beadlocks that deliver performance without compromise, backed by our sincerity-first approach.