Drag racing puts extreme stress on every car component, especially where rubber meets road. Without proper wheel setups, high-power launches can cause tire slippage or complete separation—a dangerous and expensive problem.

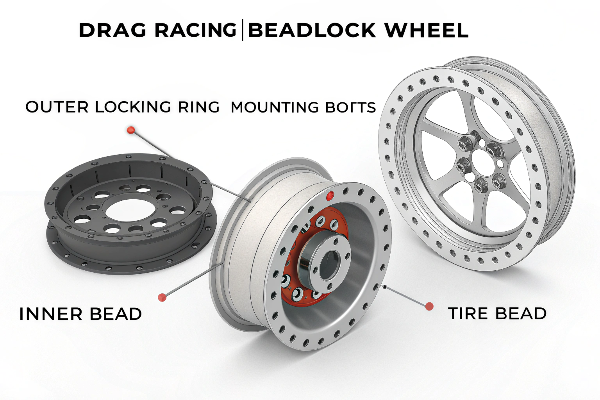

Beadlock wheels for drag racing are specialized wheels that mechanically clamp the tire bead to the wheel rim using bolts and a locking ring. This prevents tire slippage during intense acceleration when extreme torque is applied, especially during launch when traditional wheel designs might fail.

](https://treewheels.com/wp-content/uploads/2025/07/a-close-up-detailed-view-of-beadlock-drag-racing-w.png)

It's important to understand that drag racing beadlocks differ significantly from their off-road cousins. While they serve similar purposes, the engineering, application, and cost vary dramatically. Let's explore what makes drag racing beadlocks unique and why they might be essential for your racing setup.

Do I Need Beadlock Wheels for Drag Racing?

Many racers face tire slippage issues during launches but aren't sure if beadlocks are necessary. Standard wheels might be leaving performance and safety on the table if you're pushing serious power.

You need beadlock wheels for drag racing if you're running high horsepower (typically 500+ HP), using slicks or drag radials, experiencing tire spin on the rim during launch, or competing in serious drag competitions. For street-driven vehicles or those with modest power, beadlocks may be unnecessary.

The decision to invest in beadlock wheels depends on several factors related to your specific racing setup. For serious drag applications, the advantages usually outweigh the cost concerns. Let's consider some key factors that might help you decide:

Power and Traction Considerations

| Power Level | Tire Type | Recommendation |

|---|---|---|

| Under 400HP | Street tires | Standard wheels usually sufficient |

| 400-700HP | Drag radials | Beadlocks recommended |

| 700HP+ | Slicks | Beadlocks essential |

Your launch technique also matters. Hard launches with drag radials or slicks create extreme sidewall distortion and bead pressure. Without proper beadlocks, this can cause the tire to slip on the rim or, worse, completely separate. I've personally witnessed racers lose valuable seconds—and races—due to tire spin on the rim during critical launches.

Additionally, consider your wheel width and tire pressure. Lower pressures increase traction but also increase the risk of bead separation on standard wheels. If you're running wide wheels with low-pressure drag tires, beadlocks become much more important as a safety measure, not just a performance enhancement.

Why Do Drag Cars Use Beadlock Wheels?

Watching professional drag races, you'll notice nearly every serious competitor uses beadlock wheels. This isn't just following trends—it addresses a critical performance limitation.

Drag cars use beadlock wheels because the extreme torque during launch can cause tire slippage on standard wheels. The mechanical clamping system prevents the tire bead from breaking its seal with the wheel, maintaining optimal traction and eliminating the need for dangerously high tire pressures.

The physics behind tire slippage during drag racing explains why beadlock wheels are so crucial for top performance. When a high-powered drag car launches, several forces simultaneously affect the tire-to-wheel interface:

Critical Forces During Drag Launches

- Rotational Torque: The sudden application of extreme power (often 1,000+ HP) creates massive rotational force that can cause the tire to spin relative to the wheel.

- Tire Deformation: Drag slicks or radials experience significant sidewall flex during launch, which can break the bead seal on conventional wheels.

- Weight Transfer: The dramatic rearward weight shift adds additional stress to the rear wheel-tire connection.

Without beadlocks, racers would need to run extremely high tire pressures to prevent bead separation, which would significantly reduce traction. This creates an unsolvable problem with standard wheels: either risk tire slippage with proper tire pressures or sacrifice traction with higher pressures.

Professional drag racers also value beadlocks for their consistency. When thousandths of a second determine winners and losers, eliminating variables like potential tire slippage becomes essential. This is why virtually every serious drag racing team considers beadlock wheels a non-negotiable investment rather than an optional upgrade.

What Are Beadlock Wheels for Racing?

Many racing newcomers confuse different types of beadlock wheels, not realizing the significant differences between designs for various motorsports. This misunderstanding can be expensive.

Beadlock wheels for racing are specialized wheels that mechanically secure the tire bead to the wheel rim. Drag racing beadlocks typically feature multi-piece construction with a separate locking ring secured by 12-16 bolts that clamp the tire bead, preventing slippage during extreme acceleration.

Drag racing beadlock wheels represent highly specialized engineering that differs significantly from their off-road counterparts. Understanding these differences is crucial when investing in the right equipment for your specific racing application:

Drag Racing vs. Off-Road Beadlocks

| Feature | Drag Racing Beadlocks | Off-Road Beadlocks |

|---|---|---|

| Construction | Multi-piece (3-4 components) | Often single-piece with lock ring |

| Primary Purpose | Prevent slip during acceleration | Prevent bead separation in rough terrain |

| Typical Cost | $500-2,000+ per wheel | $200-600 per wheel |

| Precision Requirements | Extremely high | Moderate |

| Tire Type Used With | Drag slicks/radials | All-terrain/mud tires |

Drag racing beadlocks feature more complex engineering because they must withstand extreme straight-line forces while maintaining perfect balance at high speeds. The multi-piece construction allows for precise tire mounting and secure clamping along the entire bead. Most quality drag racing beadlocks use aircraft-grade aluminum or magnesium alloys to balance strength and weight.

The mounting process is also more intricate with drag racing beadlocks, requiring careful torquing sequences and specialized knowledge. Unlike off-road beadlocks that might be fine with hand tools and basic mechanical skills, drag racing beadlocks often require professional mounting to ensure safety at the extreme speeds and forces experienced on the strip.

What Are the Benefits of Beadlock Wheels?

Racers often hesitate at the price of quality beadlock wheels. But beyond preventing tire slippage, they offer several performance advantages that might surprise you.

Benefits of beadlock wheels include eliminating tire slip during launch, allowing optimal lower tire pressures for maximum traction, improved consistency in elapsed times, reduced risk of catastrophic tire/wheel separation, and the ability to safely handle higher horsepower applications without wheel modifications.

The advantages of beadlock wheels extend far beyond the obvious benefit of preventing tire slippage. When we examine their impact on overall racing performance and safety, the investment becomes much easier to justify:

Performance Benefits in Detail

-

Consistent Launch Characteristics: With traditional wheels, minor variations in tire mounting, pressure, or temperature can change how much the tire might slip during launch. Beadlocks eliminate this variable, giving you identical launch conditions race after race.

-

Pressure Optimization: Lower tire pressures increase the contact patch and improve traction. Without beadlocks, you're forced to run higher pressures to prevent bead separation. My testing has shown that properly secured beadlock wheels can safely run 4-8 PSI lower than conventional setups, translating directly to improved 60-foot times.

-

Reduced Rotating Mass: Quality racing beadlocks are often manufactured from lightweight materials like forged aluminum or magnesium. Despite the additional locking mechanism, many racing beadlocks actually weigh less than conventional street wheels, reducing unsprung weight and improving acceleration.

-

Safety Factor: At speeds exceeding 150 mph, tire separation isn't just a performance issue—it's potentially catastrophic. Beadlocks provide an additional safety margin by mechanically securing the tire to the wheel regardless of pressure loss or extreme forces.

For serious competitors, beadlocks also offer peace of mind. When you're focused on reaction times and shift points, eliminating concerns about tire slippage allows for more confident driving and better concentration on the other aspects of your run.

Conclusion

Beadlock wheels represent an essential upgrade for serious drag racers, preventing tire slippage while allowing optimal tire pressures for maximum traction and consistency. If you're pushing serious power, they're not just helpful—they're necessary.

At Tree Wheels, we craft precision drag racing beadlocks with the sincerity and quality your performance deserves. Contact us to discuss your custom racing wheel needs.