The automotive aftermarket is flooded with wheel options, but not all meet crucial safety standards. Many customers risk their safety with untested wheels, unaware of potential catastrophic failures under real-world driving conditions.

Quality forged wheels must meet multiple international standards including JWL, VIA, TÜV, SAE J2530, and ISO standards. These certifications verify a wheel's structural integrity through load rating tests, impact resistance evaluations, and material quality assessments to ensure safety under various driving conditions.

At Tree Wheels, we don't see testing standards as mere bureaucratic hurdles—they're vital safety guarantees. Each wheel we produce undergoes rigorous dynamic balancing and radial/axial runout testing before leaving our factory. These tests are non-negotiable parts of our quality control process. True quality isn't just visible in a wheel's appearance but is proven through these unseen testing protocols. Let me guide you through the standards that matter most in the industry.

What is the JWL Standard for Wheels?

Many wheel buyers see certification stamps but don't understand their significance. This lack of knowledge can lead to purchasing inadequately tested wheels that may fail under stress.

JWL (Japan Light Alloy Wheel) is a rigorous Japanese testing standard for aftermarket wheels. It evaluates structural integrity through rotating bending fatigue tests, impact resistance assessments, and material composition analysis. The more stringent JWL-VIA certification adds additional dynamic cornering fatigue testing.

standard testing procedure [JWL](https://wheelsape.com/pages/what-does-jwl-and-jwl-t-marked-on-the-wheels-mean) certification testing process](https://treewheels.com/wp-content/uploads/2025/09/image-2-jwl-standard-testing-procedure-tech-i.png)

The JWL standard is something I consider one of Asia's most demanding wheel certifications. Through my experience working with Japanese clients, I've noticed they place significantly higher importance on JWL certification compared to other markets. At Tree Wheels, we don't just meet basic JWL requirements—we achieve the more stringent JWL-VIA standard, which is particularly crucial for high-performance vehicles.

JWL testing evaluates wheels through several critical procedures:

Key Components of JWL Testing

| Test Type | Purpose | What It Reveals |

|---|---|---|

| Rotating Bending Fatigue | Simulates continuous wheel rotation under load | Long-term structural durability |

| Impact Resistance | Tests wheel resilience against sudden impacts | Real-world pothole and curb strike performance |

| Material Analysis | Evaluates alloy composition and quality | Consistent strength throughout the wheel |

For wheels that carry the additional VIA certification, dynamic cornering fatigue testing is added. This simulates the lateral forces experienced during aggressive cornering—something particularly relevant for performance applications. Meeting JWL-VIA standards means a wheel has proven its ability to withstand not just straight-line stress but also the complex forces encountered during spirited driving.

Who Makes the Best Forged Wheels?

Consumers often struggle to differentiate between marketing claims and genuine quality when choosing wheel manufacturers. This confusion can lead to overpaying for mediocre products or undervaluing truly superior options.

The best forged wheel manufacturers combine advanced materials science with precision manufacturing processes. Top-tier producers utilize aerospace-grade aluminum alloys, maintain strict quality control protocols, offer comprehensive customization options, and employ multi-stage testing beyond minimum required standards.

As the founder of Tree Wheels, I believe "best" is determined by multiple factors: material quality, manufacturing processes, customization capabilities, and consistency. Our advantage lies in blending traditional forging techniques with modern CNC machining while offering unparalleled customization options. We may not be the largest manufacturer, but the dedication and technology we invest in each wheel ensures our products maintain exceptional quality standards.

The forged wheel industry has several notable players, each with particular strengths. What truly separates exceptional manufacturers from adequate ones is their approach to the entire production ecosystem:

Critical Factors in Superior Forged Wheels

- Material Selection: Premium manufacturers start with higher-quality aluminum billets with precisely controlled alloy compositions

- Forging Pressure: The best wheels are created using higher pressure during forging, creating denser molecular structures

- Heat Treatment Expertise: Advanced thermal processing creates the optimal balance between strength and flexibility

- Machining Precision: State-of-the-art CNC equipment with tolerances measured in microns, not millimeters

- Finishing Technologies: Multi-stage surface treatments that enhance both appearance and durability

At Tree Wheels, we've developed our manufacturing processes by combining traditional craftsmanship with cutting-edge technology. Our partnership with specialized manufacturing facilities gives us complete control over the supply chain—from raw material selection through final quality verification. This holistic approach is what enables us to produce wheels that perform exceptionally under the most demanding conditions.

What Does SAE J2530 Mean?

Vehicle owners often encounter wheel certification labels without understanding their significance. This knowledge gap can lead to improper wheel selection that compromises vehicle safety and performance.

SAE J2530 is a comprehensive American standard developed by the Society of Automotive Engineers for aftermarket wheels. It specifies test procedures for radial fatigue, cornering fatigue, impact resistance, and material properties to ensure wheels withstand real-world driving stresses and maintain safety in diverse conditions.

certification testing [SAE J2530](https://www.wheelership.com/blog/the-importance-of-j-2530-certification?srsltid=AfmBOorRPCSiDkiup0A_JaZq2tOKhSwVUuON8EV81IPPrifdeo9S9e3I) testing equipment](https://treewheels.com/wp-content/uploads/2025/09/image-4-sae-j2530-certification-testing-line-.png)

SAE J2530 is a standard I particularly value—it's far more comprehensive than many realize. Rather than merely testing basic structural integrity, it evaluates wheel performance under extreme conditions. While many competitors simply highlight their testing compliance, at Tree Wheels, we use SAE J2530 standards to guide our entire design and manufacturing process, not just as final verification.

The J2530 standard encompasses several rigorous testing protocols that simulate real-world conditions:

SAE J2530 Testing Components

| Test Procedure | Simulation Purpose | Safety Implication |

|---|---|---|

| Radial Fatigue | Continuous straight-line driving | Prevents structural failure during highway use |

| Cornering Fatigue | Forces experienced during turns | Ensures wheel integrity during hard cornering |

| Impact Testing | Pothole strikes and curb impacts | Validates wheel's ability to absorb sudden shocks |

| Material Analysis | Consistency throughout the wheel | Confirms uniform strength with no weak points |

What makes SAE J2530 particularly valuable is its holistic approach. Rather than focusing on a single aspect of performance, it creates a comprehensive performance profile. At Tree Wheels, we've integrated these testing principles into our design philosophy. Every wheel we create is engineered from the ground up to not just pass these tests but to exceed standards by a substantial margin. This approach ensures our customers receive wheels that maintain their structural integrity even under the most demanding driving conditions.

Are OEM Wheels Forged or Cast?

Car buyers often assume all factory wheels share similar manufacturing methods and quality levels. This misconception can lead to unrealistic expectations when comparing aftermarket options to original equipment.

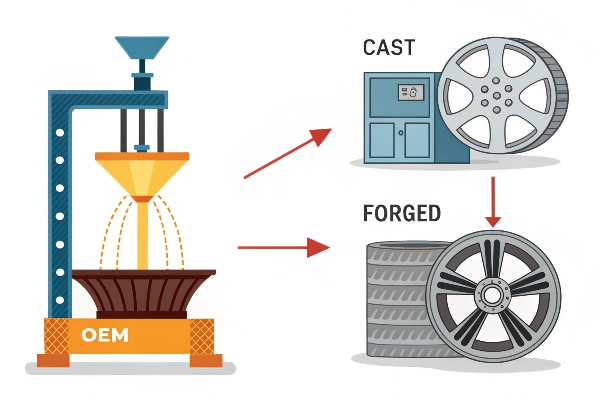

Most OEM (Original Equipment Manufacturer) wheels are pressure die-cast aluminum due to cost efficiency and manufacturing speed. However, premium and performance-oriented vehicles increasingly feature forged wheels as factory equipment, particularly when weight reduction and strength are prioritized for performance or efficiency gains.

This question comes up frequently in my conversations with clients. Most OEM wheels are indeed cast, primarily for cost considerations. However, high-end models from manufacturers like Porsche, Ferrari, and others increasingly use forged wheels as factory equipment. Through our collaborations with some OEM suppliers, I've observed the market trending toward lighter, stronger forged solutions, especially in the electric vehicle sector, where weight reduction directly impacts range.

The OEM wheel landscape has evolved significantly in recent years, with manufacturing methods chosen based on the vehicle's positioning and performance requirements:

OEM Wheel Manufacturing Approaches

- Standard Production Vehicles: Typically use gravity cast or low-pressure cast wheels to balance cost and adequate performance

- Mid-tier Performance Models: Often employ flow-formed (rotary-forged) wheels as a compromise between cast and fully forged options

- Premium Performance Vehicles: Increasingly specify fully forged wheels, especially for larger diameter applications where weight reduction becomes more critical

- Electric Vehicles: Growing trend toward forged wheels as manufacturers seek to offset battery weight and extend range

- Special Editions: Limited production models frequently feature forged wheels as part of their performance-oriented specifications

What's particularly interesting is how the electric vehicle revolution is changing OEM wheel specifications. The weight savings provided by forged wheels directly translates to extended driving range—a critical selling point. At Tree Wheels, we're seeing increased interest from electric vehicle manufacturers and modification specialists seeking to upgrade from stock cast wheels to our lightweight forged alternatives. Our testing consistently shows that a set of our forged wheels can reduce unsprung weight by 30-40% compared to cast OEM equivalents, delivering meaningful performance and efficiency improvements.

Conclusion

Wheel testing standards ensure safety and performance beyond mere appearances. Understanding JWL, SAE J2530, and manufacturing differences helps you make informed decisions for your vehicle. Tree Wheels delivers quality that exceeds standards through meticulous testing and superior craftsmanship.