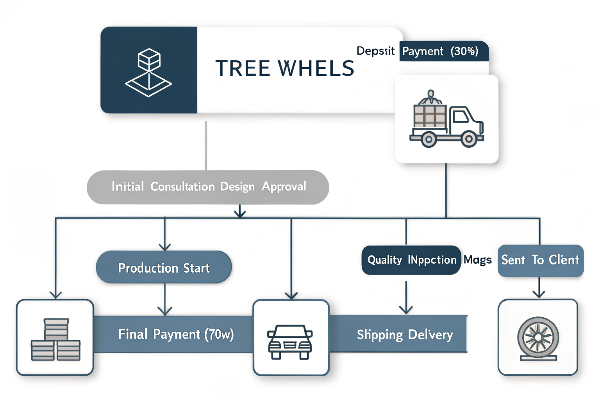

Custom forged wheels are a significant investment. As a manufacturer, I've seen clients struggle with unexpected payment terms that cause project delays and frustration. Understanding standard payment structures before ordering can save you headaches and keep your wheel project on track.

When ordering custom forged wheels, the industry standard payment term is typically a 50% deposit upfront after price approval, followed by the remaining 50% before shipping. This process includes design approval stages with 3D renderings and engineering analyses before production begins.

Working with clients worldwide for years, I've learned that payment terms can make or break the custom wheel ordering experience. Let me walk you through what you should expect when ordering premium forged wheels and why these terms exist in our industry.

Why Are Forged Wheels So Expensive?

The sticker shock of custom forged wheels often surprises first-time buyers. How can a set of wheels cost as much as a decent used car? The answer lies in what you don't see behind the scenes.

Forged wheels are expensive because they require specialized multi-million-dollar equipment, premium aluminum alloys costing 3-4 times more than cast materials, and 15-30 hours of skilled labor per wheel. Each wheel also undergoes extensive engineering, including 3D modeling, CAD design, and FEA strength testing.

At TreeWheels, our manufacturing process begins long before metal meets machine. When you pay that 50% deposit, you're not just securing a production slot—you're funding a comprehensive engineering process. We immediately begin developing detailed 3D renderings and CAD drawings tailored to your specific vehicle and performance requirements.

The forging process itself requires immense pressure and precision. Our hydraulic presses apply up to 10,000 tons of force to premium aluminum billets, creating a grain structure that's dramatically stronger than cast wheels. This equipment represents millions in investment that smaller manufacturers simply can't match. The raw materials alone cost substantially more—aerospace-grade aluminum alloys that provide the perfect balance of strength and weight.

| Cost Factor | Forged Wheels | Cast Wheels |

|---|---|---|

| Raw Materials | Premium aerospace-grade aluminum | Standard aluminum alloy |

| Material Cost | 3-4x higher | Baseline |

| Equipment Required | Multi-million dollar hydraulic presses | Conventional casting equipment |

| Labor Hours Per Wheel | 15-30 hours | 5-10 hours |

| Engineering Process | Custom 3D renderings, CAD design, FEA testing | Limited customization |

| Quality Control Points | 8-12 inspections | 3-5 inspections |

Each wheel must pass through multiple machining stages, each requiring specialized operators and quality control checkpoints. Custom finishes add another layer of complexity, with some multi-stage processes adding days to production time. Our most intricate finishes require hand-polishing and specialized coating processes that cannot be automated. The extensive pre-production engineering work—ensuring your wheels will handle your vehicle's specific weight, torque, and driving conditions—adds tremendous value but significant cost to the final product.

Who Makes The Best Forged Wheels?

When clients ask me who makes the best forged wheels, I could simply name-drop prestigious brands. However, the true answer requires a more nuanced understanding of what "best" means for your specific needs.

The best forged wheel manufacturers combine technical expertise with customization capabilities. Top-tier producers like HRE, BBS, Vossen, and TreeWheels differentiate themselves through consistent quality control, comprehensive engineering validation, and the ability to precisely meet specific performance requirements rather than offering one-size-fits-all solutions.

At TreeWheels, we've benchmarked our processes against industry leaders worldwide. What separates truly exceptional manufacturers isn't just equipment or marketing—it's their approach to engineering and quality control. The best manufacturers invest heavily in pre-production validation, which is why we provide comprehensive FEA strength analysis before a single piece of metal is cut.

| Manufacturer Comparison | Production Capabilities | Pre-Production Services | Quality Control | Customer Support |

|---|---|---|---|---|

| TreeWheels | One-piece, two-piece, three-piece forged | 3D renderings, CAD drawings, FEA analysis | Tolerances to 0.001", full testing reports | Direct engineer access, video updates |

| Industry Leader A | Limited to one-piece and two-piece | Basic renderings, limited testing | Standard industry testing | Dealer network only |

| Industry Leader B | Full range capabilities | Comprehensive engineering | Excellent QC protocols | Limited direct support |

| Budget Manufacturers | Usually one-piece only | Minimal customization | Basic quality checks | Limited warranty support |

The finest wheel producers maintain incredibly tight tolerances across every dimension. When we machine our wheels, we work to tolerances measured in thousandths of an inch, ensuring perfect fitment and performance. Our testing protocols exceed industry standards because we understand that wheels are safety-critical components. Each wheel undergoes radial and rotational fatigue testing that simulates years of real-world driving conditions.

Customer support also distinguishes premium manufacturers. Throughout our 50-50 payment process, we maintain constant communication, providing updates with images and videos at key production stages. The most reputable companies stand firmly behind their products with comprehensive warranties and clear communication—we provide detailed test reports with each completed order so clients understand exactly what they're receiving and why it's worth the premium price.

How Much Are Forged Wheels?

Pricing for forged wheels varies dramatically based on numerous factors, creating confusion for many buyers. Let me break down what influences these costs from a manufacturer's perspective.

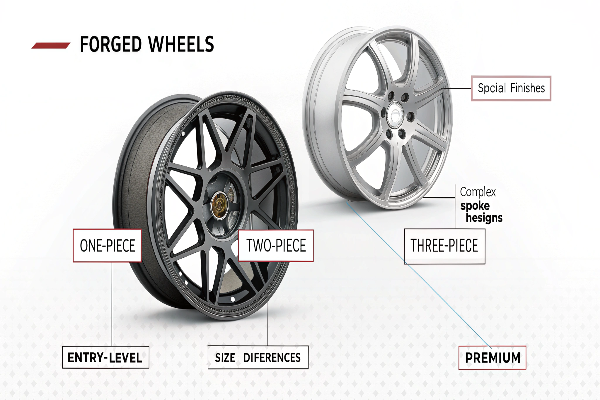

Forged wheels typically range from $1,000-$3,500 per wheel for one-piece designs, while two and three-piece wheels can cost $2,500-$5,000+ each. Pricing varies based on diameter, width, design complexity, and finish options. Custom engineering and testing services like FEA analysis are built into premium wheel prices.

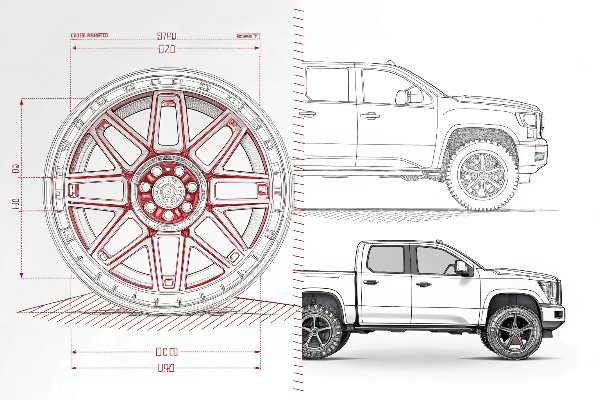

From my experience producing thousands of custom sets at TreeWheels, wheel size significantly impacts pricing. Every inch of diameter and width increases material costs and machining time. A 22-inch wheel requires substantially more raw aluminum and machine time than a 19-inch wheel of similar design. Complex spoke patterns that require intricate 5-axis CNC machining add hours to production time and thousands to the final price.

| Wheel Type | Price Range (per wheel) | Production Time | Typical Applications |

|---|---|---|---|

| One-Piece Forged | $1,000 - $3,500 | 15-20 days | Performance cars, luxury SUVs |

| Two-Piece Forged | $1,800 - $4,500 | 20-25 days | High-end luxury, motorsports |

| Three-Piece Forged | $2,500 - $5,000+ | 30-35 days | Ultra-luxury, show cars, racing |

| Additional Cost Factors | Price Impact |

|---|---|

| Basic Finish (Brushed) | +$200 per wheel |

| Complex Finish (Custom colors, tinted clear) | +$400-$600 per wheel |

| Premium Finish (Hand-polished, color-shifting) | +$800-$1,000 per wheel |

| Custom Engraving | +$200-$500 per set |

| Size Increase (per inch over 19") | +$150-$200 per wheel |

Our payment structure—50% deposit followed by 50% before shipping—helps clients manage cash flow while ensuring we can dedicate resources to their project. This deposit funds the critical pre-production phase: creating 3D renderings, CAD drawings, and conducting engineering analyses. Each wheel design is subjected to FEA (Finite Element Analysis) to simulate stress conditions specific to your vehicle, ensuring optimal performance. These engineering services represent significant value but add to the overall investment required for truly custom, high-performance wheels.

Are Forged Truck Wheels Worth It?

Truck owners often question whether expensive forged wheels make sense for vehicles that prioritize utility over performance. After producing thousands of truck wheels, I can provide clear insight into this value equation.

Forged truck wheels are worth the investment for owners seeking improved performance, fuel efficiency, and long-term durability. The significant weight reduction (typically 25-40% versus cast wheels) improves handling and fuel economy by 1-3 MPG, while superior strength handles heavy loads and withstands impacts that would damage cast wheels.

At TreeWheels, we've witnessed firsthand how dramatically forged wheels transform truck performance. The weight savings are particularly impactful on larger vehicles—a 22-inch forged truck wheel might weigh 25-30 pounds, while a comparable cast wheel could exceed 45 pounds. This reduction in unsprung weight improves acceleration, braking, and suspension response immediately noticeable to drivers.

| Performance Comparison | Forged Truck Wheels | Cast Truck Wheels |

|---|---|---|

| Average Weight (22" wheel) | 25-30 lbs | 40-45+ lbs |

| Weight Reduction | Baseline | 25-40% lighter |

| Fuel Economy Improvement | 1-3 MPG better | Baseline |

| Impact Resistance | Maintains structure after impacts | May crack or deform |

| Load Capacity | Higher due to improved strength | Standard |

| Long-term Durability | Excellent | Good to fair |

| Initial Investment | $1,200-$3,500 per wheel | $400-$1,200 per wheel |

Our truck customers consistently report fuel economy improvements of 1-3 MPG after switching to our forged wheels. For commercial users putting significant mileage on their vehicles, this efficiency gain creates a measurable return on investment over time. The performance benefits extend beyond efficiency—reducing rotational mass improves steering response and reduces strain on suspension components, potentially extending their service life.

Durability represents perhaps the most compelling argument for forged truck wheels. Our comprehensive testing program subjects truck wheels to impact forces exceeding those encountered in real-world conditions. The results consistently show that forged wheels maintain structural integrity after impacts that crack or permanently deform cast alternatives. For off-road enthusiasts and commercial users in challenging environments, this durability translates to fewer replacements and greater confidence in remote areas.

Our payment structure for truck wheels follows the same 50-50 model, with the same rigorous design process. The detailed strength analysis reports we provide are particularly valuable for commercial clients who need documentation of weight ratings and load capacities. While the initial investment is higher, the total cost of ownership makes forged truck wheels a financially sound decision for serious users.

Conclusion

Understanding standard payment terms for forged wheels helps set proper expectations and ensures a smooth ordering process. The 50% deposit/50% final payment structure reflects the custom nature and engineering intensity of premium wheels. TreeWheels combines industry-leading technology with transparent payment terms to deliver wheels that transform your vehicle's performance and appearance.