You're struggling to find the perfect wheel fitment for your vehicle. Standard options just don't work, and wheel offset confusion is making your customization journey frustrating. Let me help solve this problem.

Custom forged wheels offer virtually any offset from extreme negative (-100) to high positive (+60) values, depending on available blanks and designs. For unique offsets beyond this range, custom forging is possible but requires significant investment in new molds and tooling.

options Custom wheels with different offsets](https://treewheels.com/wp-content/uploads/2025/08/1-custom-wheels-with-different-offsets-flat.png)

When I first entered the forged wheel manufacturing business, I quickly learned that offset options are a critical factor for customers seeking the perfect stance. Many people don't realize just how flexible custom wheel production can be in terms of offset possibilities, but there are some important limitations to understand.

What Is The Offset On Custom Wheels?

You've probably seen wheels that sit perfectly flush with the fender or ones that poke out aggressively. The difference between these looks often comes down to one critical measurement – offset.

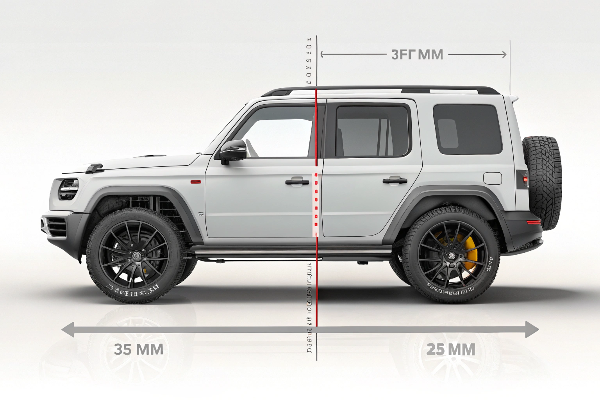

Wheel offset is the distance in millimeters between the wheel's mounting surface and its centerline. Positive offset means the mounting surface is toward the outside face (common in most modern cars), while negative offset means it's toward the inside (creating that "deep dish" look).

measurement](https://treewheels.com/wp-content/uploads/2025/08/2-diagram-explaining-wheel-offset-measurement-.png)

In my years manufacturing custom wheels, I've seen how offset fundamentally impacts both the appearance and performance of a vehicle. Understanding offset is essential whether you're a wheel shop owner or car enthusiast.

The offset measurement directly determines how your wheels will sit within the wheel wells. When a customer orders custom forged wheels, this specification is one of the most crucial factors we discuss. For production vehicles, manufacturers carefully select offset values to ensure proper clearance with suspension components, optimal handling characteristics, and correct load distribution.

Custom wheel production offers much more flexibility than off-the-shelf options. In our factory, we maintain an inventory of various wheel blanks (the raw forged pieces before machining) to accommodate different offset requirements. Standard passenger car wheels typically have offsets ranging from +15 to +45, but custom forging allows us to go well beyond these parameters. Our CNC machining centers can precisely create mounting surfaces at virtually any position within the physical constraints of the wheel design.

For high-end applications like race cars or show vehicles, we can tailor offsets to the exact millimeter based on detailed measurements of the vehicle's suspension geometry and desired aesthetic outcome.

What Offset Will Make Wheels Stick Out?

You want that aggressive stance where your wheels extend beyond your fenders, but you're confused about exactly what offset will achieve this look without causing mechanical issues or legal problems.

Negative offset wheels (typically -10 to -50) will make wheels stick out beyond the fenders. The more negative the number, the further the wheels will extend outward. However, extremely negative offsets may require fender modifications and can affect handling and legal compliance.

Vehicle with wheels sticking out due to [negative offset](https://treewheels.com/do-positive-offset-wheels-stick-out/)](https://treewheels.com/wp-content/uploads/2025/08/3-vehicle-with-wheels-sticking-out-due-to-negat.png)

During my time in wheel manufacturing, I've worked with many customers seeking that perfect aggressive stance. The relationship between offset and wheel position is something I explain almost daily.

Creating wheels that stick out (sometimes called "poke" in the customization community) requires careful consideration of several factors beyond just selecting a negative offset. When a customer approaches us for wheels with this specific look, we first need to understand their vehicle's original specifications and how far they want the wheels to extend.

| Original Offset | New Offset | Result |

|---|---|---|

| +45mm (typical factory) | +25mm | Subtle outward position |

| +45mm (typical factory) | +15mm | Moderate outward position |

| +45mm (typical factory) | 0mm | Significant outward position |

| +45mm (typical factory) | -15mm | Aggressive "poke" stance |

| +45mm (typical factory) | -30mm or lower | Extreme stance (may require modifications) |

Our H-type wheel blanks, specifically designed for more extreme negative offsets (up to about -100mm), are particularly popular for pickup trucks and SUVs where aggressive stances are common. These specialized blanks cost approximately 200 yuan more per wheel compared to standard passenger car blanks, reflecting the additional material and different forging requirements.

It's worth noting that extremely negative offsets can create several practical issues including increased stress on wheel bearings, altered steering geometry, reduced turning radius, and potential rubbing against fenders during suspension compression. We always recommend professional consultation to ensure compatibility with your specific vehicle.

What Are The Different Types Of Wheel Offsets?

You're trying to understand wheel offset terminology but feel overwhelmed by technical jargon. The difference between positive, negative, and zero offset remains confusing despite your research efforts.

There are three primary wheel offset types: positive (mounting face toward outer side), zero (mounting face aligned with centerline), and negative (mounting face toward inner side). Each creates a distinct appearance and affects handling differently.

comparison Comparison of different [wheel offset](https://www.lesschwab.com/article/wheels/what-is-wheel-offset.html) types](https://treewheels.com/wp-content/uploads/2025/08/4-comparison-of-different-wheel-offset-types-.png)

Having produced thousands of custom wheels, I've become intimately familiar with how different offset types impact both aesthetics and performance. Let me break down these different configurations for you.

| Offset Type | Typical Range | Visual Appearance | Common Applications | Manufacturing Considerations |

|---|---|---|---|---|

| Positive Offset | +35mm to +55mm | Wheels sit inward, flush or tucked under fenders | Most modern passenger cars, performance vehicles | Uses standard wheel blanks, most cost-effective |

| Zero Offset | 0mm | Balanced look with equal inner and outer depth | Custom street cars, some classic vehicles | Requires specific blanks depending on width |

| Negative Offset | -5mm to -50mm | "Deep dish" appearance, wheels extend outward | Custom show cars, lifted trucks, modified vehicles | Requires specialized blanks, higher production costs |

From a manufacturing standpoint, zero offset wheels typically require specialized blanks depending on the overall wheel width. They offer a good compromise between aesthetics and practicality, often fitting without requiring significant vehicle modifications.

Our shop can produce wheels with negative offsets approaching -100mm for specific applications like lifted trucks and custom show vehicles. These extreme negative offset wheels require our specialized H-type blanks, which come at a premium due to their unique forging requirements and lower production volumes.

What Does +35 Offset Mean?

You've spotted wheels labeled with "+35 offset" and wonder how this specific number would affect your car's appearance and performance compared to other options. The technical implications remain unclear.

A +35mm offset means the wheel's mounting surface sits 35mm outward from the wheel's centerline. This moderate positive offset is popular for aftermarket wheels as it typically positions wheels slightly more outward than factory specifications, creating a subtle enhancement to stance without clearance issues.

In my years of wheel manufacturing, +35mm has been one of our most frequently requested offset specifications, particularly for performance-oriented vehicles seeking an enhanced appearance without sacrificing functionality.

| Vehicle Type | Typical Factory Offset | Effect of +35mm Offset | Visual Impact | Performance Impact |

|---|---|---|---|---|

| Compact Sedan | +40mm to +45mm | 5-10mm outward shift | Slightly more aggressive stance, wheels align better with fenders | Minimal impact on handling, may feel slightly wider track |

| Sports Car | +45mm to +50mm | 10-15mm outward shift | Noticeably more aggressive stance | Minor changes to steering feel, wider stance can improve stability |

| SUV/Crossover | +35mm to +45mm | 0-10mm outward shift | Subtle to moderate improvement in stance | Minimal to no impact on handling |

| Luxury Sedan | +45mm to +55mm | 10-20mm outward shift | Significant improvement in stance | May noticeably alter steering feel, wider track impression |

For example, on a typical compact or mid-size sedan with factory +45mm offset wheels, switching to +35mm wheels would move each wheel outward by 10mm. This 10mm change might seem minimal on paper, but visually, it creates a noticeable improvement in stance without risking fender contact or negatively affecting handling characteristics.

From a production perspective, +35mm offset wheels fall well within our standard manufacturing capabilities using our most common wheel blanks. This makes them cost-effective to produce while still offering meaningful customization. The +35mm specification also typically provides adequate clearance for brake components on most vehicles, though we always recommend checking specific brake clearance requirements, especially for vehicles with upgraded brake systems.

Conclusion

Custom wheel offset options range from extreme negative to high positive values, with each affecting both appearance and performance. Understanding your specific needs is crucial for achieving the perfect fitment.

At Tree Wheels, we craft premium forged wheels with precision offsets to match your exact specifications, because sincerity in customization is our foundation.