Truck owners face a frustrating dilemma when shopping for rims. Mass-produced options lack personality, while custom alternatives come with sky-high prices and questionable quality. The perfect balance seems impossible to find.

The best rims for trucks combine durability, proper fitment, and style while matching your specific driving needs. Forged aluminum wheels typically offer the optimal balance of strength, weight, and customization options, with leading specialized manufacturers providing better performance than budget mass-produced alternatives.

Choosing the right rims transforms both your truck's performance and appearance. Let's explore what makes certain truck rims superior and how to find the perfect set for your specific needs.

What Is the Best Rim Brand for Trucks?

Truck owners often feel overwhelmed by countless rim brands promising unbeatable performance. With prices ranging from budget to premium, it's challenging to determine which brands truly deliver on their promises.

The best truck rim brands combine manufacturing expertise, quality materials, and rigorous testing. While major brands like Fuel, Method, and Black Rhino offer reliable mass-produced options, specialized custom forged wheel manufacturers like Tree Wheels provide superior strength-to-weight ratios and personalized designs.

When evaluating truck rim brands, I've learned that manufacturing approach matters more than brand recognition. Each category serves different needs and budgets, but understanding the differences helps make informed decisions.

Mass-produced cast wheels from established brands like Fuel and Method dominate the market due to their accessibility and recognizable designs. These brands offer consistent quality at reasonable price points, making them popular choices for truck enthusiasts seeking immediate solutions with proven patterns.

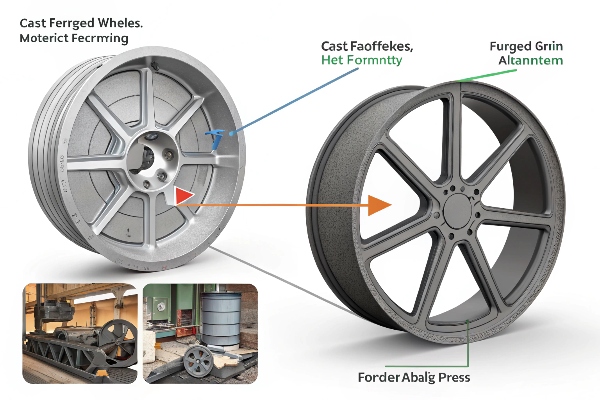

Custom forged options from specialized manufacturers present a different value proposition. Through my experience with Tree Wheels, I've seen how forged aluminum wheels created specifically for individual customers deliver superior metallurgical properties and exclusivity. The forging process aligns the metal's grain structure, resulting in wheels that can be both lighter and stronger than cast alternatives.

Here's a comparison of approaches:

| Aspect | Mass-Produced Brands | Custom Forged Specialists |

|---|---|---|

| Price Range | $200-800 per wheel | $500-2000+ per wheel |

| Production Time | Immediate (in-stock) | 15-35 days (custom made) |

| Design Options | Limited to catalog | Fully customizable |

| Strength | Good | Excellent |

| Weight | Moderate | Optimized/Lightweight |

| Exclusivity | Common designs | One-of-a-kind |

The best brand ultimately depends on your specific priorities - budget, timeline, performance needs, and desire for uniqueness.

What Type of Rims Are Most Durable?

Truck owners often damage rims on rough terrain or when hauling heavy loads. This leads to costly replacements and potential safety issues when wheels fail under demanding conditions.

Forged one-piece aluminum wheels offer the greatest durability for trucks due to their manufacturing process that aligns the metal's grain structure. Multi-piece forged wheels provide similar strength with added customization options, while quality steel wheels remain the most impact-resistant choice for extreme off-road use.

Durability comes from a combination of material, manufacturing process, and design engineering. I've analyzed thousands of wheel applications and found clear patterns in what creates lasting performance.

Forged one-piece wheels represent the gold standard for durability. The manufacturing process involves applying extreme pressure to heated aluminum billets, creating a dense, aligned grain structure throughout the wheel. This produces a wheel that can be up to 300% stronger than cast alternatives while actually weighing less. The absence of joints eliminates potential failure points, making them ideal for trucks facing varied terrain or carrying substantial loads.

Multi-piece forged wheels follow closely in durability while offering greater design flexibility. By creating separate components (typically center, inner barrel, and outer lip) from forged materials, then precisely assembling them, manufacturers can create complex designs without sacrificing significant strength. The engineering challenge comes at the connection points, which must be properly designed and assembled.

Steel wheels, though heavier, remain relevant specifically for extreme impact resistance. Their ductility allows them to bend rather than break under severe impacts, making them suitable for hardcore off-roading where rock strikes are common.

The construction method matters as much as the material:

| Construction | Strength | Weight | Customization | Best Use Case |

|---|---|---|---|---|

| Forged 1-Piece | Highest | Low | Moderate | Performance/All-Purpose |

| Forged Multi-Piece | Very High | Moderate | High | Show/Performance Balance |

| Flow-Formed | High | Moderate | Moderate | Budget Performance |

| Cast | Moderate | High | High | Street Use |

| Steel | High Impact | Very High | Low | Extreme Off-Road |

Proper engineering matters regardless of construction - even the strongest materials fail when poorly designed. Leading manufacturers employ Finite Element Analysis (FEA) testing to optimize designs for specific load patterns trucks encounter.

What to Avoid When Buying Rims?

Truck owners frequently make costly mistakes when purchasing rims, falling for flashy designs without considering compatibility or quality issues. These errors often lead to poor fitment, reduced performance, and even safety hazards.

When buying truck rims, avoid incorrect sizing (especially improper offset and bolt patterns), exceeding load ratings, choosing excessively heavy designs, and purchasing from manufacturers without proper testing certifications like ISO and TÜV. Also beware of counterfeit products and unrealistically low prices.

After years in the truck rim industry, I've witnessed numerous purchasing mistakes that lead to regret. Understanding these pitfalls can save significant time and money.

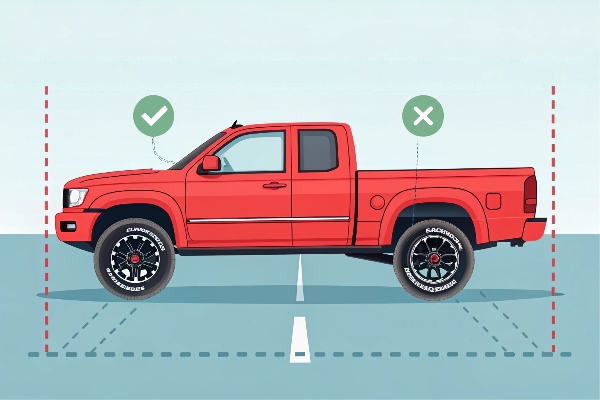

Incorrect sizing represents the most common and potentially dangerous mistake. Truck rims require precise specifications beyond just diameter and width. Offset (how the wheel sits in relation to the hub mounting surface) affects handling, clearance, and stress on suspension components. Even small variances can cause rubbing against brake components or fenders, leading to premature tire wear or dangerous driving conditions.

Load rating ignorance is equally problematic. Every wheel has a maximum weight capacity that must exceed your truck's requirements. This becomes critical for working trucks or those with heavy accessories like winches or steel bumpers. Manufacturers like Tree Wheels employ FEA testing specifically to guarantee strength across various load scenarios.

Here's what to verify before purchasing:

| Critical Specification | Why It Matters | How to Verify |

|---|---|---|

| Bolt Pattern | Must precisely match your truck | Check manual or measure existing wheels |

| Offset | Affects stance, clearance, handling | Manufacturer spec or measure existing wheels |

| Hub Bore | Ensures proper centering | Check manual or measure existing hub |

| Load Rating | Must meet vehicle weight requirements | Verify with wheel manufacturer |

| Certification | Ensures safety standards met | Look for ISO, DOT, TÜV markings |

Another trap is choosing rims based solely on appearance without considering weight implications. Excessively heavy wheels create unsprung weight that negatively impacts acceleration, braking, fuel economy, and even suspension component lifespan. Forged wheels often provide the best balance between strength and weight.

Counterfeit wheels present a serious concern, particularly with popular designs. These typically lack proper engineering, material quality, and testing. Warning signs include dramatically lower pricing than competitors, vague manufacturing information, or missing certification marks.

What Is the Best Material for Truck Rims?

Truck owners struggle to navigate conflicting claims about rim materials. Steel, cast aluminum, and forged aluminum all have vocal advocates, creating confusion about which truly delivers the best performance for different driving needs.

Forged aluminum alloys represent the best material for most truck rims, offering superior strength-to-weight ratio, excellent durability, and resistance to corrosion. For extreme off-road use, steel remains valuable for impact resistance, while chrome finishes should generally be avoided due to durability concerns.

Material selection fundamentally shapes a wheel's performance characteristics. Through my experience testing different materials in varied environments, I've developed clear insights on their relative strengths.

Forged aluminum stands out as the premier material for most truck applications. The forging process aligns the metal's grain structure, eliminating the microscopic air pockets and inconsistencies found in cast wheels. This results in a wheel that can be designed with thinner walls while maintaining superior strength. A properly engineered forged aluminum wheel typically weighs 20-40% less than a comparable cast wheel.

This weight reduction delivers significant performance benefits:

- Improved acceleration and braking

- Enhanced fuel economy

- Reduced strain on suspension components

- Better heat dissipation for brakes

- Reduced unsprung weight for better handling

The specific aluminum alloy also matters significantly. Most premium manufacturers use 6061-T6 or similar aerospace-grade alloys, which contain precise amounts of magnesium and silicon to optimize strength characteristics.

Manufacturing process comparison:

| Process | Material Structure | Strength | Weight | Price | Best For |

|---|---|---|---|---|---|

| Forged | Dense, aligned grain | Highest | Lowest | Premium | Performance, All-purpose |

| Flow-Formed | Cast face, worked barrel | High | Moderate | Mid-range | Value performance |

| Cast | Random grain structure | Moderate | Highest | Economy | Street use, visual impact |

| Steel | Uniform, ductile | High impact | Very high | Economy | Extreme conditions |

Steel wheels still maintain relevance specifically for extreme conditions. Their ability to bend rather than crack during severe impacts makes them ideal for hardcore rock crawling or environments where wheel damage is expected. However, their significant weight penalty makes them suboptimal for most other truck applications.

Surface treatments like chrome plating affect both appearance and durability. While visually striking, chrome finishes tend to be vulnerable to environmental damage, particularly in areas using road salt or with extreme temperature variations. Powder coating and advanced ceramic coatings offer superior durability for most environments.

Conclusion

The best truck rims balance proper fitment, material quality, and manufacturing excellence. Forged aluminum wheels from specialized manufacturers deliver optimal performance and personalization, making them the superior choice for discerning truck owners seeking both functionality and unique style.