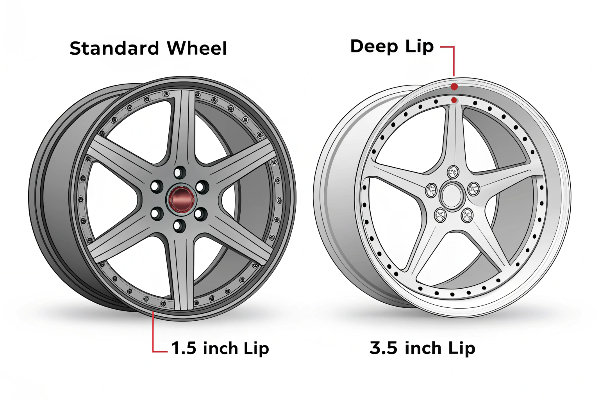

Having trouble finding wheels that make your car stand out from the crowd? Regular wheels are everywhere, making your ride blend in rather than turn heads. Deep lip wheels could be your solution.

Deep lip wheels are custom wheels featuring an extended outer edge (lip) that extends further than standard wheels. They're typically constructed using a multi-piece design, most commonly with 2-piece or 3-piece forging methods to achieve the dramatic extended edge appearance.

As a professional wheel manufacturer specializing in custom forged wheels, I've seen firsthand how the right set of deep lip wheels can transform a vehicle's appearance. The extended lip creates a striking visual effect that immediately draws attention and gives your car that aggressive stance enthusiasts crave.

Are Deep Dish Rims Good?

Are you wondering if deep dish rims are worth the investment? Standard wheels might look fine, but they don't create the same visual impact or customization possibilities that deep dish options offer.

Deep dish rims are excellent for achieving a distinctive, aggressive aesthetic that standard wheels cannot match. They provide better fitment options for vehicles with wide fenders and allow for greater personalization through custom offsets, widths, and finishes.

I've worked with numerous clients, particularly Mustang owners, who specifically request deep lip designs for their vehicles. The appeal goes beyond mere aesthetics. Deep dish wheels allow for precise fitment tailoring that's simply impossible with one-piece wheels.

| Aspect | One-Piece Wheels | Deep Dish (Multi-Piece) Wheels |

|---|---|---|

| Design Flexibility | Limited by casting/forging constraints | Highly customizable lip depth and offset |

| Aesthetic Impact | Standard appearance | Dramatic, attention-grabbing look |

| Fitment Options | Fixed specifications | Adjustable width and offset for perfect fitment |

| Customization | Limited to finish options | Components can be mixed, matched, and finished individually |

| Visual Presence | Subtle | Aggressive, premium appearance |

The multi-piece construction splits the wheel into separate components – typically the center section, inner barrel, and outer lip. This design approach allows for much more dramatic lip dimensions than what's possible with one-piece wheels. For customers who want that flush, aggressive look without rubbing issues, deep dish designs provide the perfect solution through custom backspacing and offset adjustments.

What Are the Disadvantages of Deep Dish Rims?

Considering deep dish rims but concerned about potential drawbacks? Many enthusiasts focus only on the impressive aesthetics but overlook important practical considerations that might affect performance and maintenance.

Deep dish rims typically weigh more than standard wheels due to their multi-piece construction. They're also more expensive, require specialized cleaning techniques for the complex surfaces, and offer less protection for the tire sidewall in some configurations.

In my experience manufacturing various wheel styles, the disadvantages of deep dish rims come down to several key factors that customers should consider before making their purchase.

| Disadvantage | Description | Mitigation Strategy |

|---|---|---|

| Structural Integrity | Multi-piece construction has connection points that can be weak spots | Increased spoke thickness and premium materials |

| Weight | Heavier than one-piece counterparts due to hardware and structural requirements | Advanced forging techniques to minimize weight gain |

| Maintenance | Requires periodic hardware inspection and specialized cleaning | Regular maintenance schedule and proper cleaning tools |

| Cost | Significantly higher manufacturing cost due to complex assembly | Modular design allows for component replacement instead of full wheel |

| Load Rating | Generally lower than comparable one-piece wheels | Engineering adjustments to ensure safety standards are met |

| Corrosion Risk | Hardware and connection points may be susceptible to corrosion | Premium hardware with protective coatings |

The load rating hierarchy is clear: one-piece wheels offer the highest strength, followed by two-piece, and finally three-piece designs. This doesn't mean three-piece wheels are unsafe – far from it – but it does require additional engineering considerations. To compensate for this structural difference, we often increase spoke thickness in our three-piece forged wheels to ensure they meet proper load ratings and safety standards.

Do Deep Rim Wheels Make a Difference?

Wondering if deep rim wheels truly transform a vehicle's look, or if they're just an expensive novelty? Many car enthusiasts debate whether the investment delivers real visual impact or performance benefits.

Deep rim wheels dramatically alter a vehicle's stance and presence by creating visual weight at the wheel arches. They enhance the perceived width and aggression of the car while allowing for custom fitment that can improve handling through optimized wheel width, offset, and tire combinations.

From my perspective as a wheel manufacturer who has worked with countless custom builds, deep rim wheels absolutely make a substantial difference in both aesthetics and functionality.

| Impact Area | Standard Wheels | Deep Rim Wheels |

|---|---|---|

| Visual Presence | Factory-like appearance | Premium, customized look with dimensional depth |

| Stance | Limited impact on vehicle profile | Dramatically enhances vehicle stance and presence |

| Fitment Precision | Limited options based on available sizes | Precise control over offset, width, and position |

| Tire Options | Limited by wheel width constraints | Can accommodate wider tire setups for improved grip |

| Customization Flexibility | Fixed design once purchased | Components can be changed/updated over time |

| Visual Weight Distribution | Balanced appearance | Creates emphasis on wheel arches and lower profile |

| Brake Clearance | Fixed design limitations | Can be engineered to accommodate larger brake systems |

The multi-piece construction of deep rim wheels allows for precise fitment customization that can meaningfully improve handling characteristics. For example, with a three-piece wheel, we can create offset combinations that position the tire perfectly under the fender while maintaining ideal scrub radius for steering feel. This level of precision simply isn't possible with mass-produced one-piece wheels.

What Is the Purpose of Deep Dish Wheels?

Curious why deep dish wheels have become so popular in the automotive customization scene? Their distinctive look catches attention, but many wonder if they serve any practical purpose beyond aesthetics.

Deep dish wheels primarily serve aesthetic purposes by creating a dramatic, customized appearance that emphasizes a vehicle's stance. They also allow for custom width and offset combinations that can accommodate wider tires, brake upgrades, and precise fitment for vehicles with modified suspension or body modifications.

showing the dramatic lip profile deep dish wheels with exposed hardware](https://treewheels.com/wp-content/uploads/2025/07/image-5-deep-dish-wheels-with-exposed-hardware-st.png)

The fundamental purpose of deep dish wheels extends beyond simple visual enhancement, though that remains their primary appeal. As someone who designs and manufactures custom wheels, I've observed that deep dish configurations solve several practical challenges for modified vehicles.

| Purpose | Benefit | Typical Application |

|---|---|---|

| Aesthetic Enhancement | Creates dramatic visual impact and premium appearance | Show cars, high-end builds, stance builds |

| Custom Fitment | Allows precise offset and width adjustments | Widebody kits, fender flares, lowered vehicles |

| Brake Accommodation | Provides clearance for upgraded brake systems | Performance builds, track cars |

| Modular Design | Enables component replacement and style updates | Long-term builds with evolving requirements |

| Wide Tire Fitment | Supports mounting of wider performance tires | Drift cars, performance builds |

| Fender Clearance | Allows for tucking or flush mounting based on preference | Stance builds, show cars |

| Bolt Pattern Options | Accommodates unusual or multiple bolt patterns | Conversion builds, custom applications |

| Hardware Aesthetics | Offers visible or hidden hardware options | Show applications with specific style requirements |

For drift and show car applications, deep dish wheels fulfill another important purpose – creating a visual foundation that grounds the vehicle and enhances its stance. The extended lip creates a visual connection between the tire and the wheel that emphasizes width and aggression, complementing lowered suspensions and body modifications.

Conclusion

Deep lip wheels offer unmatched customization and visual impact for modified vehicles, despite some trade-offs in weight and maintenance. When properly engineered, they deliver both style and function. At Tree Wheels, we create deep lip forged wheels with sincerity above all, balancing stunning aesthetics with uncompromising safety.