You've seen those deep concave wheels on performance cars and want that aggressive look for your ride. But pushing wheel concavity too far risks rubbing issues, compromised handling, and even structural failure.

The maximum safe wheel concavity depends on your vehicle's suspension setup, fender clearance, and brake components. Most vehicles can safely accommodate moderate concavity (15-25mm inset from the outer lip), while extreme concavity often requires suspension modifications and may affect handling characteristics.

[wheel concavity](https://treewheels.com/can-three-piece-forged-wheels-achieve-the-seamless-look-of-a-one-piece-design/) comparison](https://treewheels.com/wp-content/uploads/2025/07/image-prompt-1-wheel-concavity-comparison-crea.png)

As a forged wheel manufacturer, I've seen countless customers chase the deepest concave profile possible without understanding the technical limitations. While we can certainly produce wheels with extreme concavity, whether they'll work properly on your specific vehicle is another question entirely. Let me break down what you need to know about maximizing wheel concavity without sacrificing performance.

How much do rims affect performance?

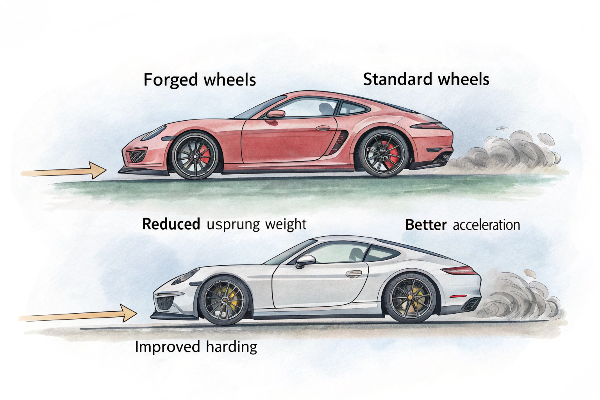

Your choice of wheels significantly impacts vehicle dynamics, affecting everything from cornering ability to ride comfort. Most drivers underestimate just how much these circular components influence their driving experience.

Wheels affect performance through weight, rotational inertia, width, diameter, offset, and rigidity. Lighter wheels improve acceleration and braking by reducing unsprung weight. Wider wheels increase cornering grip but may reduce straight-line stability. Proper wheel selection balances aesthetics with handling characteristics.

Dive deeper into wheel performance factors, and you'll find it's not just about looks. When we design forged wheels at Tree Wheels, we consider several critical performance variables. Weight is perhaps the most significant factor - a reduction of even a few pounds per wheel creates noticeable improvements in acceleration, braking distance, and suspension response. This is why our forging process is so valuable; it creates wheels that are typically 25-40% lighter than cast alternatives while maintaining superior strength.

Wheel width affects the tire's contact patch with the road. Wider wheels generally allow for wider tires, increasing the contact patch and potentially improving grip. However, there's a sweet spot - go too wide, and you'll increase rolling resistance and potentially cause rubbing issues with your fenders or suspension components.

| Wheel Aspect | Performance Impact | Aesthetic Impact |

|---|---|---|

| Weight | Lighter wheels improve acceleration, braking, and ride quality | Minimal visual impact |

| Width | Wider wheels can increase grip but may reduce straight-line stability | Wider stance, more aggressive look |

| Concavity | Deep concave wheels may require offset changes that affect handling | Dramatic visual appeal, more aggressive stance |

| Material | Forged wheels offer better strength-to-weight ratio than cast | Premium appearance, especially with machined finishes |

What effect will fitting wheel rims with a larger negative offset have on scrub radius?

Changing wheel offset is one of the most misunderstood aspects of wheel fitment. Many enthusiasts push for extreme negative offsets without realizing the significant impacts on steering geometry and handling dynamics.

Fitting wheels with larger negative offset (wheels sitting further outward) increases the scrub radius - the distance between the steering axis and the center of the tire contact patch. This increased scrub radius results in greater steering effort, more tramlining on uneven roads, and accelerated wear on steering components.

[scrub radius](https://treewheels.com/can-i-replace-17-inch-wheels-with-18-inch/) diagram](https://treewheels.com/wp-content/uploads/2025/07/image-prompt-3-scrub-radius-diagram-create-a-t.png)

The relationship between wheel offset and scrub radius deserves careful consideration when selecting wheels with aggressive concavity. In the wheel manufacturing process at Tree Wheels, we frequently consult with customers about their vehicle's original specifications to recommend appropriate offset ranges. When you decrease offset (more negative), you're effectively moving the wheel's mounting surface outward relative to the wheel centerline.

This change extends beyond mere aesthetics - it fundamentally alters your vehicle's steering geometry. The scrub radius is the distance between where your steering axis intersects the ground and the center of your tire's contact patch. A properly designed suspension has an optimal scrub radius that balances steering feel, stability, and component longevity.

Increasing negative offset typically increases scrub radius, which can lead to several unwanted effects:

Steering Feel Changes

- Heavier steering effort, especially at low speeds

- More pronounced feedback from road imperfections

- Increased steering kickback on bumpy surfaces

Component Stress

| Component | Impact of Increased Negative Offset |

|---|---|

| Ball joints | Accelerated wear due to increased leverage |

| Wheel bearings | Higher lateral loads and potential premature failure |

| Tie rod ends | Greater stress during steering inputs |

Additionally, excessive negative offset can cause the tire to extend beyond the fender line, which may violate local regulations in many countries and regions. This is why we recommend consulting with suspension specialists when pursuing aggressive concavity that requires significant offset changes.

How do bigger rims affect performance?

The trend toward larger diameter wheels continues to grow, with many customers requesting 20+ inch designs without understanding the performance implications. Size matters—but not always in the way enthusiasts expect.

Bigger diameter wheels typically reduce acceleration due to increased rotational mass but can improve cornering stability and brake clearance. The key performance factors are total wheel-tire package weight and maintaining appropriate sidewall height. Excessive diameter with low-profile tires often worsens ride quality and increases vulnerability to impact damage.

s [wheel diameter](https://treewheels.com/do-aftermarket-wheels-affect-performance/) comparison](https://treewheels.com/wp-content/uploads/2025/07/image-prompt-4-wheel-diameter-comparison-creat.png)

When designing custom forged wheels for our clients, we often have conversations about the ideal diameter for their specific application. The move to larger diameter wheels has both performance benefits and drawbacks that must be carefully weighed. From a manufacturing perspective, we can produce wheels in virtually any diameter, but what works best for your vehicle requires deeper consideration.

Increasing wheel diameter while maintaining the same overall tire diameter (by reducing sidewall height) affects several performance parameters. Most notably, the reduction in sidewall flexibility changes how the suspension interacts with the road. With less tire sidewall to absorb impacts, more energy transfers directly to the suspension components and ultimately to the vehicle's occupants.

Performance Implications of Larger Wheel Diameters:

Handling Characteristics

Larger wheels with lower profile tires generally provide:

- More responsive steering inputs

- Reduced sidewall flex during cornering

- Better stability during high-speed maneuvers

- More precise feedback through the steering wheel

Ride Quality Considerations

| Aspect | 17" Wheel | 19" Wheel | 22" Wheel |

|---|---|---|---|

| Ride Comfort | Excellent | Moderate | Reduced |

| Impact Absorption | High | Moderate | Minimal |

| Road Noise | Lower | Moderate | Higher |

| Vulnerability to Damage | Low | Moderate | High |

From a manufacturing standpoint, larger diameter wheels also require additional engineering considerations. The structural integrity becomes increasingly important as diameter grows, which is why our forged construction process is particularly valuable for larger wheels. The density and alignment of the aluminum grain structure in forged wheels provide superior strength-to-weight characteristics compared to cast alternatives, allowing us to create larger wheels that remain both strong and relatively lightweight.

Are concave wheels good?

Concave wheels have surged in popularity primarily due to their aggressive aesthetic appeal, but their performance implications extend beyond mere looks. Many enthusiasts question whether this design choice offers genuine benefits.

Concave wheels can be beneficial when properly engineered, offering potential weight reduction in the wheel face and improved brake cooling through increased airflow. However, excessive concavity often requires compromised offset that can negatively affect handling. The ideal concavity balances aesthetic desires with your vehicle's specific suspension geometry.

From our perspective as wheel manufacturers at Tree Wheels, concavity isn't simply an aesthetic choice – it's an engineering consideration that affects multiple aspects of wheel performance. The primary attraction of concave wheels is undoubtedly their visual impact – they create a sense of depth and aggression that flat-faced wheels simply cannot match. However, there are genuine functional considerations as well.

When we design concave wheels, we're actually removing material from the face of the wheel, which can reduce weight in the wheel's central section. This weight savings, while minimal compared to overall wheel weight, occurs in an advantageous location – reducing mass near the center of rotation has less impact on rotational inertia than removing the same weight from the wheel's periphery.

The increased open space in concave designs can also improve airflow around brake components. For high-performance applications with large brake calipers, this improved cooling effect can help maintain consistent brake performance during aggressive driving sessions.

Concavity Considerations by Vehicle Type:

| Vehicle Type | Recommended Concavity Approach | Rationale |

|---|---|---|

| Performance Sedans | Moderate concavity with minimal offset changes | Maintains handling characteristics while achieving desired aesthetics |

| Show Cars | Deep concave with appropriate suspension modifications | Prioritizes visual impact over daily driveability |

| Track/Race Cars | Minimal to moderate concavity focused on weight reduction | Performance benefits outweigh aesthetic considerations |

| SUVs/Trucks | Limited concavity with appropriate load ratings | Must maintain structural integrity for heavier vehicles |

It's worth noting that achieving extreme concavity often requires significant offset changes, which circles back to our earlier discussion about scrub radius and handling implications. This is why at Tree Wheels, we always recommend a balanced approach – seeking the maximum concavity that works within your vehicle's mechanical constraints rather than pushing beyond them and compromising performance.

Conclusion

Maximizing wheel concavity requires balancing aesthetic desires with technical considerations specific to your vehicle. While deep concave wheels create stunning visual impact, they must be properly engineered to maintain performance and safety.

At Tree Wheels, we craft custom forged wheels that deliver both the aggressive look you want and the performance your vehicle deserves.