You notice a crack in your rim and panic sets in. The thought of buying new wheels brings financial stress, but driving on damaged rims feels risky. What should you do?

Fixing a cracked rim is generally not worth it for structural damages. Minor scratches can be repaired through repainting or polishing, but deep cracks compromise safety and performance. For structural damage, complete replacement is the safer, more cost-effective long-term solution.

cracked aluminum wheel rim](https://treewheels.com/wp-content/uploads/2025/07/image-1-cracked-aluminum-wheel-rim-create-a-rea.png)

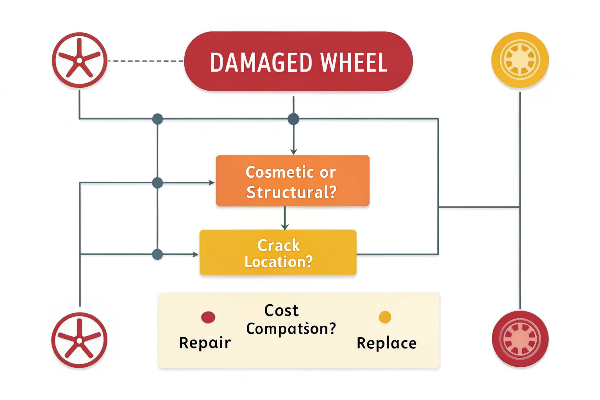

When facing rim damage, many drivers wonder if repair is a viable option. The answer depends on the type and extent of damage. Let's explore whether repairing a cracked rim makes sense financially and from a safety perspective, or if replacement is the better option.

Should I Repair a Cracked Rim?

Your once-perfect wheel now shows a visible crack. You're wondering if repair is possible or if you're facing an unavoidable replacement expense.

You should only repair a cracked rim. Structural cracks, splits, or fractures that affect the rim's integrity cannot be safely repaired and require complete replacement to maintain driving safety.

Understanding what type of damage can be repaired is crucial for making an informed decision. Not all rim damage is created equal. From our years of manufacturing experience, we've learned to categorize rim damage into two main types: cosmetic and structural.

Cosmetic damage includes:

- Surface scratches from curb scrapes

- Minor scuffs that don't affect performance

- Paint chips or clear coat damage

- Light corrosion on the finish

These issues can often be repaired through professional refinishing services, polishing, or repainting. The wheel maintains its structural integrity, and repairs focus purely on restoring appearance.

Structural damage, however, is entirely different:

- Cracks that extend into the barrel or spokes

- Bends that change the wheel's geometry

- Fractures around lug bolt holes

- Any damage affecting the airtight seal with the tire

As manufacturers, we design wheels with precise stress calculations. Once a structural crack occurs, the metal's integrity is compromised in ways that welding or other repair methods cannot fully restore. The wheel can never regain its original strength and safety characteristics.

Many repair shops might offer to weld cracks, but this creates a false sense of security. The heat from welding actually changes the metal's properties around the repair site, potentially creating new weak points. This is why, as manufacturers, we cannot endorse structural repairs on safety-critical components like wheels.

How Much Does It Cost to Fix a Cracked Rim?

When you discover a cracked rim, cost concerns quickly follow. You're caught between spending money now or potentially facing bigger expenses later.

Cosmetic rim repairs typically cost $125-250 per wheel, while structural repair attempts run $150-400. However, complete replacement—the only safe solution for structural cracks—costs $250-1000+ per wheel depending on material and design. Aftermarket options may offer better value than dealer replacements.

The cost of wheel repairs varies significantly based on several factors that I've observed through our manufacturing and distribution channels. Understanding the true cost implications helps buyers make more informed decisions.

| Repair Type | Average Cost Range | When Appropriate | Long-term Value |

|---|---|---|---|

| Cosmetic Refinishing | $75-200 | Surface scratches, scuffs | Good when properly done |

| Paint/Powder Coating | $100-250 | Finish damage, minor corrosion | Good for appearance only |

| Structural Welding | $150-400 | Never recommended | Poor - creates false security |

| Complete Replacement | $250-1000+ | Structural damage | Excellent - restores safety |

Beyond the immediate repair costs, there are hidden expenses that many vehicle owners don't consider. A poorly repaired wheel can lead to:

- Increased tire wear (uneven contact patches)

- Reduced fuel efficiency (from imbalance)

- Damage to suspension components (from vibration)

- Potential blowouts or failures at highway speeds

From our manufacturing perspective, the metallurgical properties of a wheel are permanently altered when a crack occurs. The repair process itself, particularly welding, creates heat-affected zones where the metal's crystalline structure changes. This fundamentally weakens the wheel in ways that aren't visible to the naked eye but become critical during emergency maneuvers or impacts.

When customers focus only on immediate costs, they often miss the bigger financial picture. A quality replacement wheel is an investment in safety that typically delivers better value over time compared to a series of escalating problems from a compromised repair.

Is It Safe to Drive on a Cracked Rim?

You spot a crack in your rim but have places to go. The temptation to postpone dealing with it is strong, but nagging safety concerns won't go away.

Driving on a cracked rim is never safe. Even hairline cracks can suddenly expand under driving forces, potentially causing catastrophic tire failure, loss of vehicle control, or accidents. A cracked rim requires immediate attention and should not be driven on except in emergencies.

As wheel manufacturers, we engineer our products to withstand enormous stresses—from cornering forces to pothole impacts to the constant weight of the vehicle. A crack in any part of the wheel means the structural integrity has been compromised in a significant way.

The physics behind wheel failure is concerning. Wheels are subjected to multiple force types:

- Radial forces - The weight of the vehicle pressing downward

- Lateral forces - Side pressures during turning and cornering

- Impact forces - Sudden shocks from road hazards

- Rotational forces - Torque from acceleration and braking

- Thermal expansion/contraction - Temperature changes affecting metal

A crack creates a stress concentration point where these forces multiply. What might start as a small, seemingly insignificant crack can rapidly expand under the right conditions. This effect is especially pronounced in aluminum alloy wheels, which are designed with precisely calculated strength-to-weight ratios leaving little margin for structural compromise.

Our testing procedures have demonstrated that wheel failures rarely occur gradually—they tend to happen suddenly and catastrophically. When a wheel fails at highway speeds, the consequences can include:

- Immediate loss of air pressure

- Vehicle pulling sharply to the affected side

- Loss of steering control

- Potential rollover in severe cases

The risk isn't worth taking, especially when you consider that a wheel failure doesn't just endanger the driver but everyone else on the road. Even driving slowly on a cracked rim can cause the crack to expand or damage other components like brake calipers, suspension parts, or the tire itself.

Is It Better to Fix a Rim or Replace It?

Your damaged rim presents a dilemma: invest in repairs to save money now, or replace it entirely for potentially better long-term value?

For structural damage like cracks, replacement is always better than fixing a rim. While repairs may seem economical initially, replaced wheels provide restored safety, performance, and peace of mind. Only minor cosmetic damage should be repaired, as structural repairs compromise safety and often cost more over time.

Making the right decision between repair and replacement requires understanding the true costs and benefits beyond the initial price tag. As manufacturers, we see the consequences of both choices throughout the wheel's lifecycle.

The decision process should consider several factors:

Safety Considerations

Nothing outweighs safety in this equation. A properly manufactured new wheel meets all safety standards and load ratings. Our production facilities use precise metallurgical processes that cannot be duplicated in repair shops. Heat treatments, alloy compositions, and manufacturing tolerances are all carefully controlled to create a wheel that performs predictably under stress.

Repaired wheels, particularly those with structural damage, introduce unpredictable variables. The wheel's ability to distribute forces evenly becomes compromised, creating weak points that may fail at critical moments.

Performance Impact

Wheels aren't merely aesthetic components—they're precision instruments that affect:

| Performance Factor | Impact of New Wheel | Impact of Repaired Wheel |

|---|---|---|

| Tire Wear | Even, predictable | Often uneven, accelerated |

| Fuel Economy | Optimized | Potentially reduced |

| Handling | Factory-specified | May be compromised |

| Comfort | Balanced ride | Possible vibrations |

| Braking | Even heat dissipation | Potentially uneven |

Long-term Economic Analysis

While a repair might save money initially, the total cost of ownership often favors replacement:

- Reduced tire lifespan from improper wheel geometry

- Additional repairs as cracks reappear or expand

- Increased fuel consumption from weight imbalance

- Potential damage to other components (bearings, suspension)

- Lower resale value of the vehicle

Based on our industry experience, we've seen customers spend more on multiple repairs and associated problems than they would have on a straightforward replacement. Quality replacement wheels don't necessarily mean expensive OEM parts—many aftermarket options provide excellent quality at competitive prices.

For drivers focused on both safety and value, replacement offers the best combination of immediate peace of mind and long-term economic sense.

Conclusion

Fixing a cracked rim is rarely worth it when structural damage exists. Always prioritize safety by replacing structurally compromised wheels. At Tree Wheels, we craft custom forged wheels that deliver both safety and style—because your peace of mind on the road is priceless.