Starting an alloy wheel manufacturing business requires significant investment, technical knowledge, and understanding of market demand. But where should you begin? In this post, I'll share a guide based on my experience in China, where I've seen the alloy wheel industry grow and evolve.

Starting an alloy wheel manufacturing business may seem daunting, but with the right steps, it can be a profitable venture.

The first thing to know is that alloy wheels come in two primary types: forged and cast. Each type has different production requirements and profit potential. For casting, it's relatively simple, requiring just a die-casting machine and molds. However, cast wheels typically come with lower profit margins, higher order minimums, and less flexibility in terms of customization. On the other hand, manufacturing forged wheels demands higher standards but offers greater customization opportunities and higher-profit margins. A critical part of forging is working with specialized forging factories to produce the blanks, which you can then refine using precision CNC machinery. However, don't forget about one often overlooked cost—the environmental impact assessment. This equipment is essential and can cost millions in RMB.

How to Manufacture Alloy Wheels?

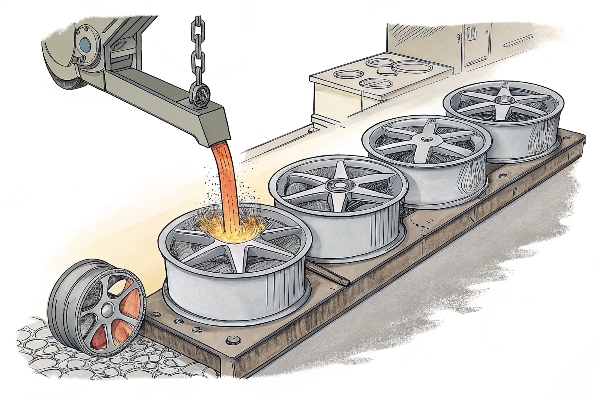

When it comes to manufacturing alloy wheels, one must choose between two primary methods: casting and forging.

Casting alloy wheels is less technically demanding and involves fewer complexities. You only need die-casting machines and molds. While the process is simple, the profit margin tends to be lower, and the minimum order quantity can be high. But there is still strong demand for cast wheels, especially in budget markets and mass production.

In contrast, forging alloy wheels offers more profit potential but is more technical. The manufacturing process starts with forging factories producing the raw blanks using high-pressure machinery. The next step requires precision CNC machines to refine these blanks into finished wheels. The key to success in forging lies in choosing a reliable CNC machine supplier. This investment can be costly, but the return on high-end, custom-designed forged wheels is substantial.

How to Get into the Rim Business?

To get into the rim business, it's essential to grasp both production and market dynamics.

Getting into the rim business starts with choosing the right production method for your target market. If you’re focused on high-end vehicles, forged rims are ideal. For budget-conscious customers, cast rims are a good option.

Once you've selected the production method, it's crucial to consider distribution channels, pricing strategies, and competition. A strong B2B network is essential, as most rim manufacturers sell to auto modification shops, luxury car service centers, and customization specialists. By forming partnerships with these businesses, you can establish a steady stream of orders.

Who is the Largest Manufacturer of Aluminum Wheels?

The global market for aluminum wheels is dominated by a few large manufacturers.

The largest manufacturers of aluminum wheels are typically found in the US, Europe, and Asia. Companies such as ZF Friedrichshafen, CITIC Dicastal, and Enkei are considered the leaders in the industry. These companies focus on both casting and forging methods and serve a range of industries, from automotive to luxury vehicles.

Their success can be attributed to their ability to innovate, invest in technology, and scale production. As a newcomer to the industry, understanding how these companies maintain such dominance—through advanced technology, supply chain efficiency, and strong industry partnerships—can provide invaluable lessons.

How to Start an Alloy Wheel Repair Business?

Alloy wheel repair businesses cater to car owners who need their wheels restored to a like-new condition.

Starting an alloy wheel repair business involves understanding the common types of damage and the best methods for repair. You’ll need to invest in equipment such as welding machines, CNC lathes, and resurfacing tools to restore wheels. Additionally, training in techniques such as wheel straightening, resurfacing, and refinishing is crucial to providing high-quality service.

It’s also important to develop strong relationships with auto repair shops and dealerships, who can refer customers to you. Offering a mobile service can also be a huge advantage, as it makes repairs more accessible to customers. With a good reputation and proper marketing, an alloy wheel repair business can thrive in any market.

Conclusion

Manufacturing and repairing alloy wheels requires both technical expertise and business acumen. By choosing the right production method and focusing on customer satisfaction, you can carve out a profitable niche in the alloy wheel industry. TreeWheels is here to support you with high-quality forged wheels for your business.