Many car enthusiasts face problems with inferior wheels from China. Poor quality control, unclear standards, and deceptive marketing leave buyers frustrated and vehicles unsafe.

To ensure quality wheels from China, verify the manufacturer uses high-grade aluminum alloys, owns their production line (except plating), conducts proper testing (both radial runout and dynamic balance), and holds relevant certifications like ISO, DOT, TÜV or JWL.

Finding trustworthy wheel manufacturers in China can feel overwhelming. The market is flooded with options ranging from premium forged wheels to dangerously substandard products. Understanding what happens behind the scenes in Chinese wheel factories will help you make informed decisions and avoid costly mistakes.

What are cheap rims made of?

Cheap wheels often hide dangerous secrets beneath their shiny finish. Low-quality materials and cut corners in manufacturing create ticking time bombs for your vehicle.

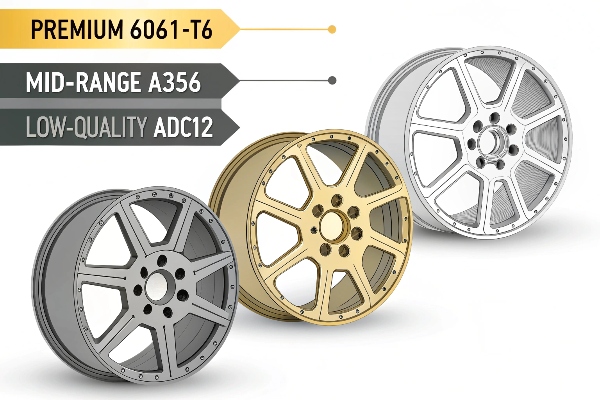

Inexpensive wheels from China typically use recycled aluminum with impurities or lower-grade alloys (like ADC12 instead of 6061-T6). These materials have weaker structural integrity, leading to cracks, bends and potential failure under stress.

Many people don't realize that wheel manufacturing in China follows a complex supply chain. Contrary to popular belief, not all processes happen under one roof. The journey begins with large factories supplying aluminum to forging plants. These specialized forging facilities then process the raw materials into wheel blanks of various sizes before delivering them to wheel manufacturers.

From there, most production steps can be completed in-house at the wheel factory, with the exception of electroplating, which is typically outsourced (we actually recommend avoiding electroplated finishes altogether, as explained in another post). Quality control must start at the source - that's why at TreeWheels, we only source our forged wheel blanks from major established suppliers like Zhejiang Hongxin, Jiangsu Poran, or Shandong Juncheng.

Using blanks from smaller, lesser-known factories significantly reduces quality while lowering prices. This explains the wide price variations you might see when comparing Chinese wheel brands. The best manufacturers maintain control over all production stages (except plating) within their own facilities. Some Chinese wheel factories outsource certain processes to specialized workshops nearby - while this creates cost efficiencies through cluster effects, it sacrifices quality control at critical stages.

| Quality Level | Material Used | Characteristics | Longevity |

|---|---|---|---|

| Premium | 6061-T6 or 7075-T6 aluminum | High strength, corrosion resistance, crack resistance | 10+ years |

| Mid-range | A356 aluminum alloy | Good strength, acceptable weight | 5-8 years |

| Low-end | ADC12 or recycled aluminum | Poor strength, higher weight, prone to cracking | 2-4 years or less |

What is the test before shipment?

Many buyers overlook crucial pre-shipment testing for wheels. Skipping these vital checks leads to safety issues, performance problems, and premature wheel failure on the road.

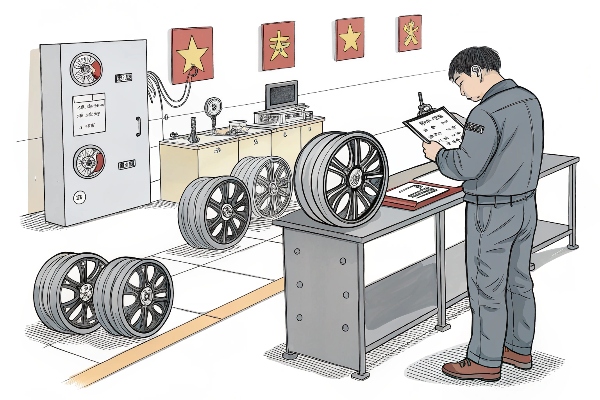

Quality wheels undergo multiple pre-shipment tests including dimensional inspection, visual inspection, air tightness test, radial/lateral runout testing, and dynamic balancing. These verify the wheels meet safety standards and will perform properly when installed.

While many wheel factories can deliver acceptable aesthetic results with proper supervision (correct dimensions, colors, and finishes), there's a dramatic difference when it comes to technical testing standards. Based on my industry experience, many manufacturers only perform radial and lateral runout tests, mistakenly believing this covers all potential issues. This assumption is dangerous and incorrect.

At TreeWheels, we've encountered special cases where wheels passed radial runout testing but failed dynamic balance tests - and vice versa. Each test measures different quality aspects, and both are absolutely essential for safety and performance. Even more concerning, some lower-tier factories use inadequate testing equipment or apply incorrect standards during these tests, rendering the results essentially meaningless.

Despite these quality control variations, China remains the world's leading wheel exporter, accounting for approximately 70% of global wheel production. Even wheels from factories with substandard testing might outperform locally-manufactured options in many countries. The average consumer might not immediately notice these subtle quality differences during everyday driving, though they affect performance, safety, and longevity.

Comprehensive pre-shipment testing includes:

| Test Type | What It Checks | Why It Matters |

|---|---|---|

| Dimensional Inspection | Exact measurements of all wheel dimensions | Ensures proper fitment on vehicles |

| Visual Inspection | Surface finish, coating quality, cosmetic defects | Verifies appearance quality and coating integrity |

| Air Tightness | Seal integrity for tubeless tire applications | Prevents air leakage and tire pressure loss |

| Radial/Lateral Runout | Wheel roundness and lateral wobble | Prevents vibration and uneven tire wear |

| Dynamic Balance | Weight distribution around wheel | Ensures smooth operation at highway speeds |

How Do Chinese Factories Test Alloy Wheels Before Shipping?

Not all Chinese wheel factories follow the same testing protocols. Inadequate testing procedures can miss critical defects that lead to dangerous road failures and expensive warranty claims.

Reputable Chinese wheel manufacturers use specialized equipment to test both static specifications (dimensions, weight, runout) and dynamic performance (balance, impact resistance). Top-tier factories also conduct batch testing for material composition and structural integrity.

The wheel testing process in Chinese factories varies dramatically based on the manufacturer's commitment to quality. Industry leaders implement comprehensive multi-stage testing regimens that go beyond standard requirements, while budget producers might perform only the bare minimum checks or even falsify documentation without proper testing.

The most significant differentiation between basic and premium manufacturers is laboratory testing capabilities. High-end factories like ours invest in expensive equipment to conduct thorough material analysis, impact resistance testing, and fatigue testing. These tests verify that wheels can withstand real-world driving conditions far beyond basic dimensional checks. We regularly analyze samples from production batches to ensure material consistency and structural integrity throughout the manufacturing process.

Another critical factor is third-party verification. While many factories claim various certifications, legitimate quality manufacturers welcome independent inspections and testing from recognized authorities. TreeWheels products undergo testing to meet international standards including ISO certification, DOT requirements, and compliance with TÜV and JWL standards - creating accountability beyond internal quality control measures.

Traceability systems represent another quality indicator - premium manufacturers implement lot tracking from raw material to finished product. This allows us to trace any quality issue back to its source, whether in materials, specific production equipment, or process parameters. This level of quality management is rarely found in budget wheel factories, which typically lack sophisticated quality management systems.

Levels of wheel testing in Chinese factories:

| Factory Tier | Testing Conducted | Documentation | Quality Control |

|---|---|---|---|

| Premium | Full spectrum material and performance testing, third-party certification | Complete test reports, material certifications, traceability | In-house QC plus third-party verification |

| Mid-range | Basic dimensional and visual testing, limited performance testing | Basic documentation, some certifications | In-house QC only |

| Low-end | Minimal visual inspection | Limited or potentially falsified documentation | Inconsistent or absent QC |

Conclusion

Sourcing quality wheels from China requires understanding the manufacturing process, material differences, and proper testing standards. Choose manufacturers who control their production and perform comprehensive testing.

For truly reliable forged wheels that meet international standards, TreeWheels delivers sincerity and quality in every custom wheel we produce.