Staring at the price tag of forged wheels often gives customers sticker shock. The vast difference between $30 cast wheels and $200+ forged options leaves many wondering if the upgrade is really worth it.

Custom forged wheels typically cost between $170-$680 per wheel depending on size and construction type. Monoblock (one-piece) forged wheels start around $170, while two-piece designs range from $395-$570, and three-piece wheels cost $480-$680.

with different designs and finishes](https://treewheels.com/wp-content/uploads/2025/08/1-custom-forged-wheels-with-different-designs-and.png)

I've been in the wheel manufacturing business for years, and the question of price justification comes up constantly. Many customers don't understand why there's such a massive price gap between cast and forged wheels. If you're trying to decide whether forged wheels deserve their premium price tag, let me break down what you're actually paying for.

How expensive are forged wheels?

Looking at premium wheels can cause serious budget anxiety. With regular cast wheels available for as little as $30 each, the jump to $200+ for forged options makes many customers hesitate.

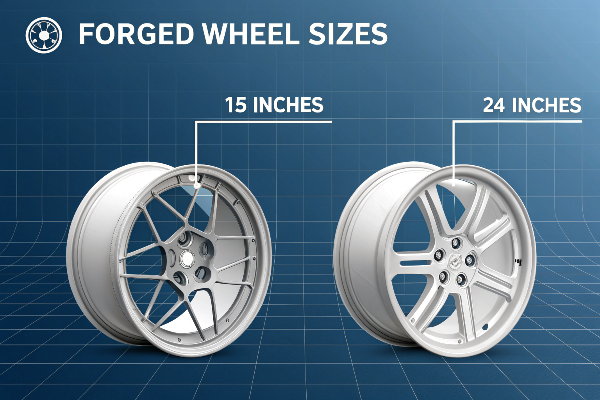

Forged wheels range from $170 for basic 15-17" monoblock designs to $680 for premium 24" three-piece constructions. Two-piece forged wheels fall in the middle at $395-$570, with prices increasing proportionally with wheel diameter.

When I show customers our price list, I always explain what factors into these costs. The manufacturing process for forged wheels is significantly more involved than cast alternatives. Our monoblock (one-piece) forged wheels represent the entry point into premium wheel territory, starting at $170 for 15-17" sizes and gradually increasing to $370 for 24" options.

For those seeking even more customization and performance benefits, our two-piece forged wheels start at $395 for 15-17" sizes and range up to $570 for 24" wheels. These provide better strength-to-weight ratios and more design flexibility than monoblocks. Our top-tier three-piece forged wheels, which offer maximum customization potential and highest performance capabilities, begin at $480 for smaller sizes and reach $680 for 24" diameter wheels.

The size-based pricing reflects not just the additional material required but also the increased manufacturing complexity and specialized equipment needed for larger wheels. Each wheel size category requires different forging pressures, tooling setups, and CNC machining parameters, which all factor into the final price point.

Forged Wheel Pricing Breakdown by Construction Type

| Wheel Size | Monoblock | Two-Piece | Three-Piece |

|---|---|---|---|

| 15"-17" | $170 | $395 | $480 |

| 18" | $190 | $410 | $500 |

| 19" | $210 | $430 | $520 |

| 20" | $225 | $445 | $535 |

| 21" | $260 | $465 | $570 |

| 22" | $295 | $500 | $610 |

| 23" | $330 | $535 | $640 |

| 24" | $370 | $570 | $680 |

Are forged rims worth it?

I often have customers question the value proposition of forged wheels. With prices 5-10 times higher than cast alternatives, the hesitation is understandable.

Forged wheels are worth the investment for performance enthusiasts, offering 20-40% weight reduction, superior strength, and enhanced driving dynamics. For daily drivers and standard vehicles, cast wheels provide adequate function at significantly lower costs.

I'm always straightforward with my customers about when forged wheels make sense and when they might be unnecessary. As a manufacturer of premium forged wheels, I could push everyone toward our high-end products, but the truth is more nuanced. The "worth it" question ultimately depends on your specific needs and priorities.

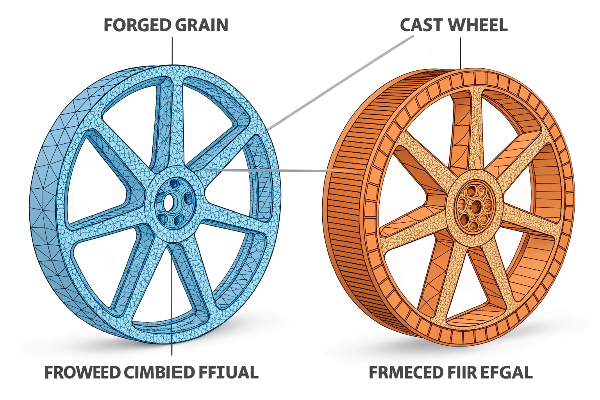

For performance applications, the benefits of forged wheels are substantial and measurable. The manufacturing process aligns the metal's grain structure like bamboo fibers, creating a wheel that's not just lighter but significantly stronger. This translates to reduced unsprung weight, which improves acceleration, braking, handling, and even fuel economy to a small degree. When a performance car shaves 40-60 pounds of rotating mass by switching to forged wheels, the impact on driving dynamics is immediately noticeable.

However, I always tell customers that if their vehicle is primarily for commuting and everyday transportation, cast wheels will likely serve them perfectly well. Many cast wheels have attractive designs that most people can't visually distinguish from forged options. In fact, I drive with cast wheels on my own daily commuter vehicle because they're perfectly adequate for regular driving.

Comparison of Cast vs. Forged Wheel Properties

| Property | Cast Wheels | Forged Wheels | Benefit of Forged |

|---|---|---|---|

| Structure | Granular | Fibrous | Enhanced strength |

| Weight | Standard | 20-40% lighter | Better performance |

| Strength | Good | Excellent | Higher safety margin |

| Production | Mass-produced | Individually crafted | Custom specifications |

| Price | $30-100 | $170-680 | Premium quality |

| Best for | Daily driving | Performance/Modification | Specialized use |

Why are forged wheels more expensive?

When customers see our price list, they often experience sticker shock. The substantial price difference between cast and forged wheels raises eyebrows and questions.

Forged wheels cost more because they're manufactured using an intensive process that compresses aluminum under extreme pressure (up to 10,000 tons), creating a stronger, lighter structure with aligned grain patterns. Each wheel is then individually CNC-machined rather than mass-produced.

process](https://treewheels.com/wp-content/uploads/2025/08/4-forged-wheel-manufacturing-process-style-reali.png)

Having overseen the production of thousands of custom wheels, I've gained intimate knowledge of what drives the pricing differences. The manufacturing processes for cast and forged wheels couldn't be more different, and this directly impacts the final cost.

Cast wheels are made by pouring molten aluminum into molds, allowing for mass production with minimal variation. This process is efficiently automated and requires little individual attention, which keeps costs low. The resulting wheels have a granular internal structure that, while adequate for everyday use, lacks the strength and resilience of forged alternatives.

In contrast, our forged wheels begin with solid aluminum billets that undergo extreme pressure compression—sometimes exceeding 10,000 tons of force. This compression fundamentally alters the metal's structure, aligning the grain patterns to create a fibrous, bamboo-like internal composition that provides superior strength with less material. After forging, each wheel must be individually machined on CNC equipment to achieve the final design specifications.

This personalized manufacturing approach continues throughout the process—each forged wheel passes through multiple stages of individual craftsmanship rather than moving along an automated assembly line. For two-piece and three-piece constructions, the complexity increases substantially, requiring precise fitment of components, specialized hardware, and additional quality control steps.

Manufacturing Cost Factors for Forged Wheels

| Production Factor | Impact on Cost | Details |

|---|---|---|

| Raw Materials | High | Premium aluminum alloys |

| Forging Process | Very High | Specialized equipment, high pressure |

| CNC Machining | High | Individual programming for each design |

| Labor | Medium-High | Skilled technicians vs. automation |

| Quality Control | Medium | Multiple inspection points |

| Customization | High | Design adaptability adds complexity |

| Production Volume | High | Small batches vs. mass production |

Conclusion

Custom forged wheels cost between $170-$680 per wheel because of their superior strength, reduced weight, and individualized manufacturing process. Whether they're worth it depends entirely on your vehicle's purpose and your performance priorities. Tree Wheels delivers premium forged wheels with sincerity above all, ensuring your investment delivers real performance benefits.