Custom forged wheels can transform your vehicle's look and performance, but waiting for them can be frustrating. Many customers ask about production times without understanding the complex manufacturing process behind these premium wheels.

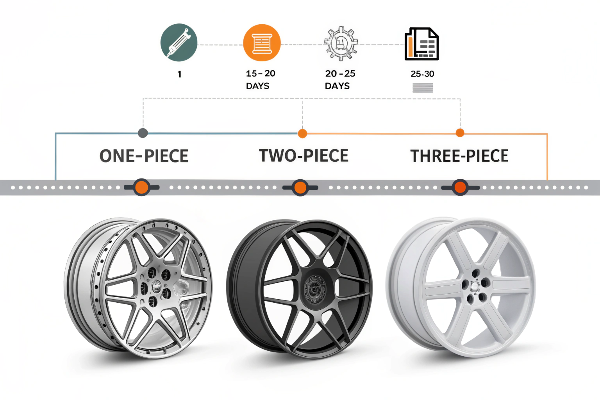

Manufacturing time for custom forged wheels varies by design complexity: one-piece wheels take 15-20 days, two-piece wheels require 20-25 days, and three-piece wheels need 25-30 days. International shipping adds 10-30 days depending on destination.

manufacturing](https://treewheels.com/wp-content/uploads/2025/08/image-1-custom-forged-wheels-manufacturing-sty.png)

As a manufacturer with years of experience in the forged wheel industry, I've seen how production timelines can make or break a customer relationship. Let's explore what affects manufacturing time and set realistic expectations for your custom wheel project.

How Long Does It Take to Make Forged Wheels?

Many wheel buyers get frustrated when their custom wheels take longer than expected. They don't realize that quality forged wheels require precise manufacturing steps and careful quality control to ensure safety and performance.

One-piece forged wheels typically take 15-20 days to manufacture, two-piece designs require 20-25 days, and three-piece wheels need 25-30 days. For international buyers, shipping adds 10 days within Asia or up to 30 days for deliveries to Europe and the Americas.

Creating premium forged wheels isn't a rushed process—each step requires precision and expertise. At Tree Wheels, our manufacturing timeline reflects our commitment to quality and craftsmanship. The complexity of your design directly impacts production time, with customization options like unique finishes or complex spoke patterns adding extra days to the schedule.

For one-piece wheels, we start with a solid aluminum billet that undergoes high-pressure forging. This 15-20 day process includes heat treatment, CNC machining, quality testing, and finishing treatments. Two-piece designs take longer (20-25 days) as we must manufacture and precisely assemble separate components. Three-piece wheels are our most time-consuming product at 25-30 days, requiring perfect alignment of the outer lip, inner barrel, and center section.

International logistics add another layer to delivery timelines. While Asian customers might receive their wheels within 10 days after production, our customers in the US, Canada, and Europe should expect roughly 30 days for ocean freight. For urgent orders, we offer air freight options that significantly reduce transit time but at a higher shipping cost.

| Wheel Type | Production Time | Asian Shipping | Americas/Europe Shipping |

|---|---|---|---|

| One-Piece | 15-20 days | +10 days | +30 days |

| Two-Piece | 20-25 days | +10 days | +30 days |

| Three-Piece | 25-30 days | +10 days | +30 days |

How Are Forged Wheels Manufactured?

When customers experience wheel performance issues, it's often because they don't understand the complex manufacturing differences between cast and forged wheels. This knowledge gap leads to unrealistic expectations about both quality and production time.

Forged wheels are manufactured by applying extreme pressure to heated aluminum billets, creating dense, strong metal structures. Unlike cast wheels, this process eliminates porosity and weak points, resulting in wheels that are 20-30% lighter yet significantly stronger than cast alternatives.

for custom wheels forged wheel manufacturing process](https://treewheels.com/wp-content/uploads/2025/08/image-3-forged-wheel-manufacturing-process-sty.png)

At Tree Wheels, our forging process begins with selecting premium aluminum alloys, typically 6061-T6 or 7075 grade aluminum known for exceptional strength-to-weight ratios. We start with solid cylindrical billets that weigh significantly more than the final product. These raw materials undergo a transformation through multiple specialized steps that each contribute to the wheel's final performance characteristics.

The forging process itself involves heating the aluminum billets to approximately 450-500°C before applying up to 10,000 tons of pressure. This extreme force rearranges the metal's grain structure to create a more uniform, denser material with superior mechanical properties. Unlike casting, where molten metal might trap air pockets or develop inconsistent cooling patterns, forging creates a consistent molecular structure throughout the wheel.

After initial forging, our wheels enter the CNC machining phase, where computer-guided precision tools remove excess material to create the final design. This stage is particularly time-intensive for complex designs with intricate spoke patterns or weight-reduction pockets. For multi-piece wheels, each component undergoes separate machining before being precision-assembled with specialized hardware.

The final stages involve surface treatment, including cleaning, priming, painting, and clear coating. Each wheel undergoes rigorous quality control testing, including dimension verification, X-ray inspection for internal integrity, and pressure testing. We also conduct specialized tests for impact resistance and load capacity to ensure every wheel exceeds international safety standards like TÜV and JWL requirements.

| Manufacturing Step | Purpose | Time Required |

|---|---|---|

| Material Selection | Ensure quality foundation | 1-2 days |

| Forging Process | Create dense, strong structure | 3-5 days |

| CNC Machining | Define wheel design | 5-10 days |

| Surface Treatment | Apply finishes and coatings | 3-7 days |

| Final QC Testing | Verify quality and safety | 2-3 days |

Where Are Specialty Forged Wheels Made?

Consumers often struggle to find reliable specialty wheel manufacturers, facing challenges with inconsistent quality and uncertain delivery times. This uncertainty creates anxiety about investing in high-performance wheels.

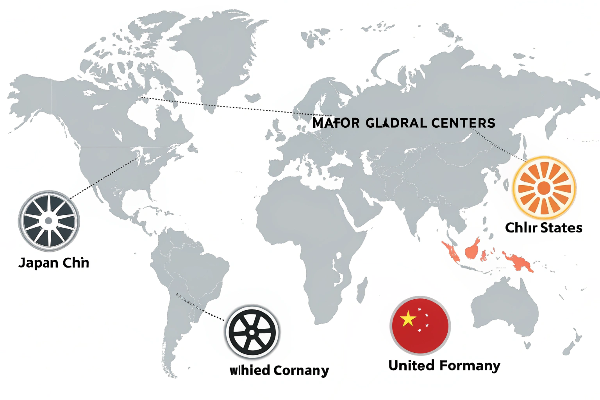

Specialty forged wheels are primarily manufactured in Japan, China, the United States, and Germany. Japan leads in ultra-premium wheels with exceptional craftsmanship, while China offers excellent quality-to-price ratio for mid-to-high end products. American and German manufacturers focus on motorsport and luxury applications.

As a Chinese manufacturer with extensive industry knowledge, I've observed the global landscape of forged wheel production evolve significantly. China has rapidly advanced its manufacturing capabilities, now producing wheels that meet international standards while maintaining competitive pricing. Our facility at Tree Wheels represents this new generation of Chinese manufacturing—combining advanced technology with strict quality control.

Japan remains the gold standard for ultra-premium forged wheels, with manufacturers like Rays and Work Wheels demonstrating exceptional attention to detail and precision. Their decades of experience and craftsmanship culture create wheels that are recognized worldwide for superior quality, though at premium price points. For customers requiring absolute perfection regardless of cost, Japanese wheels remain the benchmark.

The United States hosts several renowned manufacturers specializing in motorsport and performance applications. Companies like HRE and Forgeline have established strong reputations for domestic production of high-quality wheels with distinctive American design aesthetics. Similarly, German manufacturers like BBS focus on engineering excellence, particularly for motorsport and high-performance European vehicles.

Our manufacturing facility in Ningbo, China represents the best balance of quality, customization capability, and value. We've invested in advanced forging equipment, CNC machines, and quality control systems that allow us to produce wheels comparable to global competitors at more accessible price points. Unlike many competitors, we maintain complete control over our production process, from raw material selection through final quality control.

| Region | Quality Level | Price Range | Specialization |

|---|---|---|---|

| Japan | Exceptional | Premium | Ultra-precise, lightweight designs |

| China | Very Good to Excellent | Competitive | Customization, value-oriented |

| USA | Excellent | High | Performance, distinctive designs |

| Germany | Excellent | High | Engineering, motorsport applications |

Who Makes The Best Forged Rims?

Vehicle enthusiasts often struggle to identify truly premium wheel brands amid marketing hype. Without industry knowledge, they risk overpaying for mediocre products or missing out on exceptional quality from lesser-known manufacturers.

The best forged wheels come from specialized manufacturers with extensive engineering experience. Japanese brands like Rays and Work excel in ultra-premium segments, while American companies like HRE create distinctive luxury designs. European manufacturers like BBS focus on motorsport heritage, and select Chinese manufacturers like Tree Wheels offer exceptional value with international certification.

Determining the "best" manufacturer depends heavily on your specific requirements and budget constraints. Through my experience in wheel manufacturing, I've learned that different manufacturers excel in different aspects of wheel production. Rather than ranking manufacturers, I prefer to highlight the unique strengths that distinguish top-tier producers.

Japanese manufacturers like Rays Engineering (Volk Racing, Gram Lights) and Work Wheels have earned their reputation through exceptional precision, innovative designs, and stringent quality control. Their wheels frequently feature advanced technologies like MAT (Metal Air Technique) and specialized flow-forming processes that optimize weight reduction while maintaining structural integrity. These wheels often set the standard for fitment precision and finish quality, though they command premium prices reflecting their craftsmanship.

American manufacturers like HRE Performance Wheels and Forgeline focus on distinctive design aesthetics combined with exceptional engineering. They've built strong reputations particularly in the luxury and exotic car segments, offering extensive customization options with particular attention to finish quality and perfect fitment for high-end vehicles. Their distinctive designs often make them favorites for show cars and luxury vehicles.

Historic European manufacturers like BBS (Germany) leverage their motorsport heritage and engineering excellence. Their wheels benefit from decades of racing development, resulting in designs that emphasize structural rigidity and performance under extreme conditions. Their production processes often combine traditional craftsmanship with advanced manufacturing technology.

As a representative of Tree Wheels, I can share that premium Chinese manufacturers have made remarkable strides in recent years. Our facility combines state-of-the-art equipment with rigorous quality control systems that meet international standards. While we acknowledge that ultra-premium Japanese manufacturers still maintain an edge in certain specialized applications, our ISO and DOT certified wheels offer exceptional value while meeting TÜV and JWL standards—making them ideal for customers seeking premium quality without the extreme premium pricing of some established brands.

| Manufacturer Region | Strengths | Best For | Price Point |

|---|---|---|---|

| Japanese (Rays, Work) | Precision, weight optimization | Track use, weight-critical applications | $$$$$ |

| American (HRE, Forgeline) | Design, customization | Luxury vehicles, show cars | $$$$ |

| European (BBS, OZ) | Engineering, motorsport heritage | Performance driving, European vehicles | $$$$ |

| Chinese Premium (Tree Wheels) | Value, certification, customization | Custom projects with budget considerations | $$$ |

Conclusion

Custom forged wheels require precision manufacturing with timelines varying from 15-30 days based on design complexity, plus shipping time. Understanding these factors helps set realistic expectations for your wheel project.

At Tree Wheels, we combine quality, customization, and competitive pricing—delivering premium forged wheels built on our foundation of sincerity above all.