Wheels take brutal punishment daily. Potholes, curbs, and harsh weather constantly test their limits, yet many drivers underestimate the impact wheel quality has on performance, safety, and long-term costs.

Forged wheels outlast cast wheels significantly due to their manufacturing process. The forging process aligns the metal's grain structure, creating a stronger molecular bond that resists fatigue and cracking. This results in wheels that maintain structural integrity for 10-15+ years under normal conditions.

next to [cast wheels](https://mam-wheels.com/blog/the-tough-choice-cast-or-forged-wheels/) showing structural differences forged wheels vs [cast wheels](https://mam-wheels.com/blog/the-tough-choice-cast-or-forged-wheels/) comparison](https://treewheels.com/wp-content/uploads/2025/08/image-1-forged-vs-cast-wheels-comparison-create.png)

While forged wheels offer superior durability, the practical question isn't just about quality but value. With prices often 3-5 times higher than cast wheels, it's important to understand if the investment makes sense for your specific needs. Let's explore the complete comparison to help you make an informed decision.

What Are the Disadvantages of Forged Wheels?

Every car enthusiast dreams of upgrading to forged wheels. But the excitement often fades when they see the price tag, leaving many wondering if the premium cost truly delivers proportional value.

The main disadvantages of forged wheels include high cost (typically $3,000-$6,000+ per set), limited design options compared to cast wheels, longer production times, and more expensive repairs if damaged. They may also offer minimal practical benefits for everyday drivers who don't push their vehicles to performance limits.

of forged wheels disadvantages of forged wheels illustrated](https://treewheels.com/wp-content/uploads/2025/08/image-2-disadvantages-of-forged-wheels-illustra.png)

As a manufacturer of premium forged wheels, I believe in complete transparency about when these wheels make sense. The truth is, not everyone needs forged wheels. For daily commuters with standard vehicles, cast wheels provide excellent durability at a fraction of the cost. My own daily driver, a moderately priced vehicle, runs perfectly fine on factory cast wheels.

Forged wheels shine in specific situations. They're ideal for high-performance vehicles where every pound matters, or for custom builds where the aesthetic statement justifies the investment. The weight reduction improves acceleration, braking, and handling, while the stronger structure handles track conditions better. However, these benefits primarily matter for enthusiasts pushing their vehicles to the limit or owners of premium vehicles like Porsche, BMW, or Mercedes where the driving experience enhancement matches the investment.

Another consideration is customization lead time. While cast wheels are often available immediately, forged wheels typically require 15-35 days of production time depending on complexity, plus shipping. This means planning ahead for your wheel upgrade rather than making a spontaneous change.

How Much Stronger Are Forged Wheels Than Cast Wheels?

When shopping for wheels, you'll hear claims about forged wheels being "stronger" than cast alternatives. But the difference in strength isn't just marketing—it's measurable and significant in real-world applications.

Forged wheels are approximately 20-30% stronger than cast wheels while weighing 25-40% less. This strength-to-weight advantage comes from the manufacturing process where metal is compressed under extreme pressure (up to 9,000 tons), creating a denser, grain-aligned structure that resists bending, cracking, and fatigue.

The strength difference between forged and cast wheels becomes most apparent in demanding situations. I've witnessed firsthand how these differences play out during testing and real-world applications. When our forged wheels undergo impact testing, they typically withstand forces that would crack or completely shatter comparable cast wheels.

This strength advantage comes from fundamental differences in how these wheels are made. Cast wheels are produced by pouring molten aluminum into a mold, similar to making ice cubes. This creates a less dense structure with tiny air pockets and random grain patterns. Forged wheels, however, start as solid billets of aircraft-grade aluminum that are compressed and shaped under massive pressure.

The results are measurable across multiple strength metrics:

| Strength Measurement | Cast Wheels | Forged Wheels | Advantage |

|---|---|---|---|

| Impact resistance | Baseline | 20-30% higher | Forged |

| Fatigue resistance | Baseline | 25-35% higher | Forged |

| Weight efficiency | Baseline | 25-40% lighter | Forged |

| Tensile strength | Moderate | High | Forged |

This strength difference matters most for performance vehicles, off-road applications, or when driving frequently on rough roads. For a typical family vehicle driving on well-maintained roads, the additional strength provides minimal practical benefit beyond peace of mind.

How Long Can Forged Rims Last?

Car owners often wonder if premium wheel investments will stand the test of time. With proper care, will those expensive forged wheels truly outlast multiple vehicles, or is their longevity overstated?

Forged wheels typically last 10-20+ years under normal driving conditions, often outliving the vehicle itself. Their dense, uniform grain structure resists metal fatigue, corrosion, and structural degradation. Many owners transfer their forged wheels between multiple vehicles over decades, making them a long-term investment.

demonstration](https://treewheels.com/wp-content/uploads/2025/08/image-4-forged-wheels-longevity-demonstration-c.png)

Longevity is perhaps the most compelling argument for forged wheels when considering lifetime value. While the initial investment is substantial, the extended service life distributes the cost over many more years of use compared to cast alternatives.

From our customer feedback and industry experience, we've observed that properly maintained forged wheels often remain in excellent condition even after 15+ years of service. Many of our customers have transferred their TreeWheels forged wheels through multiple vehicle upgrades, effectively extending their investment across different cars.

Several factors contribute to this exceptional durability:

-

Material integrity - The forging process eliminates the microscopic air pockets and inconsistencies found in cast wheels that can lead to stress cracks over time.

-

Finish durability - The denser surface of forged wheels allows for finishes that bond more effectively to the metal, resulting in better resistance to flaking, peeling, and corrosion.

-

Structural resilience - Forged wheels flex slightly under impact rather than cracking, then return to their original shape. This elasticity prevents the cumulative damage that eventually compromises cast wheels.

-

Repair potential - When damage does occur, forged wheels are often repairable due to their material consistency, while cast wheels more frequently require complete replacement.

Of course, longevity depends significantly on driving conditions, maintenance, and exposure to harsh elements. Wheels subjected to extreme environments like frequent track use or severe winter conditions with road salt may require more attention to maintain their longevity advantage.

What Are the Strongest Types of Wheels?

Wheel strength matters when you're shopping for upgrades, but with marketing terms like "flow-formed," "rotary-forged," and "fully-forged" clouding the conversation, it's hard to know what truly represents the strongest option.

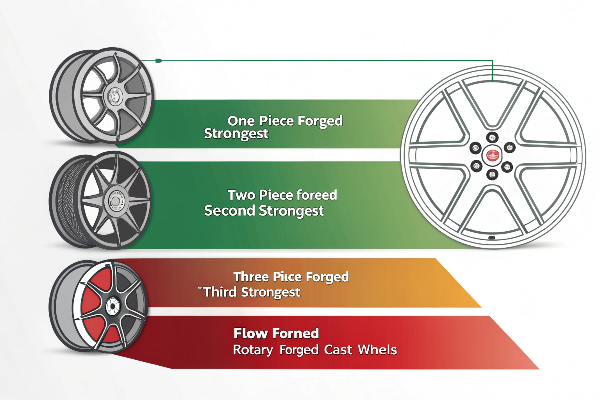

One-piece forged wheels represent the pinnacle of wheel strength with their seamless monoblock construction. The absence of joints creates the highest possible structural integrity. Two-piece forged wheels follow closely in strength, while three-piece designs offer more customization options but slightly lower overall strength due to their modular nature.

When discussing wheel strength, we need to consider multiple manufacturing methods and their resulting structures. At TreeWheels, we produce wheels across the strength spectrum, but our expertise in forged construction allows me to provide insight into the hierarchy of wheel strength.

From strongest to least strong, here's how different wheel types compare:

-

Multi-piece forged wheels - These represent the ultimate in wheel technology. Each component (center, inner barrel, outer lip) is individually forged for optimized strength, then precision-assembled. Three-piece designs offer the best combination of strength, customization, and repairability.

-

One-piece forged wheels - Created from a single billet of aluminum through an intensive forging process, these monoblock designs offer exceptional strength-to-weight ratios with no weak points from joining different components.

-

Flow-formed/rotary-forged wheels - A hybrid manufacturing process that starts with a cast wheel center but applies spinning force to the barrel portion, creating alignment in the metal grain structure. They offer about 15-20% better strength than fully cast wheels at a more accessible price point.

-

Gravity-cast wheels - The standard manufacturing process used for most factory wheels, offering adequate strength for normal driving conditions at an economical price point.

-

Low-pressure cast wheels - The most basic wheel manufacturing method, typically used for the most budget-oriented aftermarket wheels.

The performance difference becomes most apparent in extreme conditions. During professional racing or serious off-roading, the superior strength of forged wheels provides meaningful performance advantages and safety margins. For extreme applications like competitive drifting or rock crawling, multi-piece forged wheels offer both the needed strength and the ability to replace individual components if damage occurs.

Conclusion

Forged wheels offer superior durability and strength compared to cast alternatives, but their value depends entirely on your specific needs and vehicle. For daily drivers, cast wheels work perfectly fine, while performance enthusiasts gain real benefits from forged options. At TreeWheels, we craft custom forged excellence for those who demand the absolute best.