Importing forged wheels from China can seem overwhelming. You worry about quality, communication barriers, customs procedures, and getting the right specifications for your vehicle or business needs.

The process of importing forged wheels from China involves finding a reliable manufacturer, specifying your wheel requirements, negotiating terms, completing payment, and arranging shipping and customs clearance. Working with a trusted supplier who handles logistics can simplify this process significantly.

Whether you're an individual car enthusiast looking for custom wheels or a business owner planning to enter the wheel modification market, importing from China offers significant advantages. Let me break down the entire process for you based on my experience as a manufacturer of high-end forged wheels.

Are Forged Wheels Made in China?

Many car enthusiasts worry about quality when considering Chinese-made wheels. They've heard mixed stories and aren't sure if premium forged wheels can come from China.

Yes, high-quality forged wheels are manufactured in China. Over the past decade, Chinese wheel manufacturers have invested heavily in advanced forging technology, CNC machining equipment, and quality control systems to produce world-class forged wheels that meet international standards.

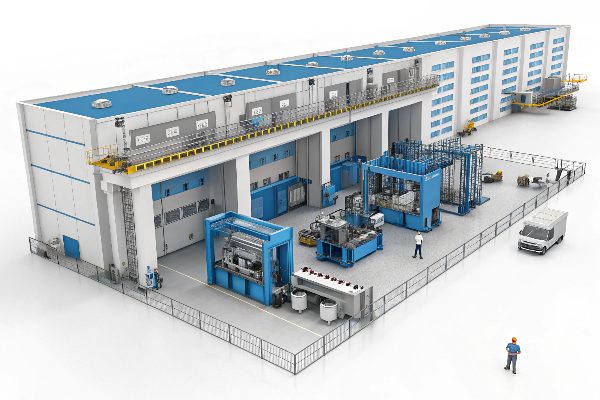

As someone involved in the production of forged wheels in China, I can provide a deeper look into the manufacturing landscape. China has emerged as a major player in the global forged wheel market due to several key advantages. Many Chinese manufacturers, including our facility at Tree Wheels, have invested in state-of-the-art equipment and technology to ensure precision manufacturing.

The forging process in China follows the same rigorous standards used globally. It begins with high-grade aluminum alloy billets (typically 6061-T6 or similar aerospace-grade material) that undergo intense pressure and heat treatment. This process aligns the metal's grain structure, creating a stronger, lighter product compared to cast wheels.

Quality control has significantly improved, with many manufacturers now implementing:

| Quality Measure | Implementation in Chinese Factories |

|---|---|

| Material Testing | X-ray fluorescence analysis to verify alloy composition |

| Structural Testing | FEA (Finite Element Analysis) for strength and impact resistance |

| Certification | ISO 9001, TÜV, JWL, and DOT compliance |

| Final Inspection | Computerized balance testing and runout measurements |

The best Chinese manufacturers also maintain transparency about their processes and are willing to provide detailed documentation about material sourcing, testing protocols, and quality certifications. This level of accountability has helped Chinese forged wheels gain acceptance in premium markets worldwide.

Where Are Forged Wheels Made?

When investing in premium forged wheels, buyers often wonder about manufacturing origins. They want to know if location affects quality and if they're getting true value for their investment.

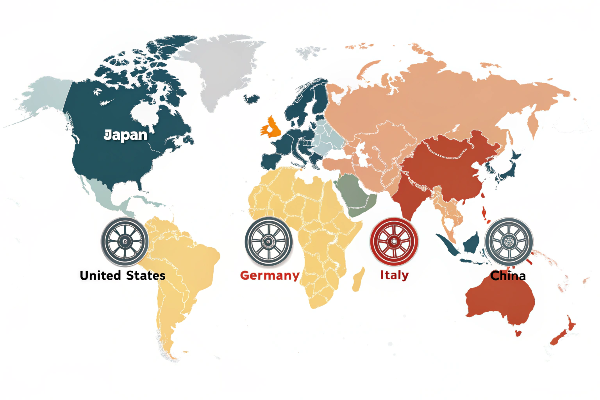

Forged wheels are produced globally, with major manufacturing hubs in Japan, the United States, Germany, Italy, and China. While Japan and Western countries were traditionally known for premium forged wheels, China has emerged as a significant player, combining advanced technology with cost advantages.

The global landscape of forged wheel manufacturing reveals interesting patterns of specialization and expertise across different regions. Each manufacturing hub brings its own strengths to the industry, influencing both design philosophies and production techniques.

Japanese manufacturers like Rays Engineering (makers of Volk Racing wheels) and Work Wheels have built their reputation on precision engineering and consistent quality control. Their wheels often feature distinctive designs that balance performance and aesthetics, with many JDM (Japanese Domestic Market) styles becoming globally popular.

American manufacturers such as HRE Performance Wheels and Forgeline focus on larger diameter wheels with designs that complement American muscle cars and luxury vehicles. These companies often emphasize customization options and create wheels that make bold styling statements.

European production, particularly in Italy and Germany, tends to focus on wheels for high-performance and luxury European vehicles. BBS from Germany and OZ Racing from Italy are known for their motorsport heritage and technical innovation.

When comparing manufacturing locations, consider these factors:

| Manufacturing Region | Typical Strengths | Common Market Focus |

|---|---|---|

| Japan | Precision, lightweight design, technical innovation | Sport compact, JDM style, racing applications |

| USA | Customization, larger sizes, bold designs | Luxury vehicles, muscle cars, trucks, SUVs |

| Europe | Motorsport heritage, OEM partnerships | European luxury and performance cars |

| China | Cost efficiency, modern equipment, rapid production | Wide range including replicas and custom designs |

At Tree Wheels, we've combined the best practices from these global traditions with our own manufacturing strengths. Our facility uses the same forging techniques and quality control measures as premium manufacturers elsewhere, while leveraging our local advantages in production efficiency and cost management.

What Are the Disadvantages of Forged Wheels?

Car enthusiasts considering forged wheels often hesitate due to the steep price. They wonder if the benefits truly justify the significant premium over cast alternatives.

The primary disadvantages of forged wheels include high cost, limited design flexibility compared to cast wheels, longer production time, and potential repair difficulties if damaged. These drawbacks must be weighed against their superior strength, lighter weight, and enhanced performance.

While forged wheels offer numerous performance advantages, it's important to have a realistic understanding of their limitations. This balanced perspective helps customers make informed decisions based on their specific needs and circumstances.

The manufacturing process itself creates some inherent constraints. Forging involves applying massive pressure to aluminum billets, which creates wheels with exceptional strength characteristics but limits design possibilities. The metal flow during forging means that certain complex geometric shapes possible with casting simply cannot be achieved with a forged process. This explains why forged wheels often feature more straightforward designs with clean lines rather than intricate patterns.

Repair considerations also present challenges. When a cast wheel is damaged, it's often easily replaced due to lower cost. However, with an expensive forged wheel, owners naturally want to repair rather than replace. The high-strength nature of forged aluminum can make repairs more difficult and costly. Not all wheel repair shops have the expertise to properly repair forged wheels without compromising their structural integrity.

Weight considerations create another paradox. While forged wheels are generally lighter than cast equivalents, achieving ultra-lightweight designs requires removing more material, which significantly increases machining time and cost. There's always a balance between:

| Factor | Forged Wheel Trade-off |

|---|---|

| Weight Reduction | Higher cost due to additional CNC machining time |

| Design Complexity | Limited by forging process constraints |

| Production Time | Longer lead times, especially for custom specifications |

| Repair Options | Fewer qualified repair facilities, higher repair costs |

At Tree Wheels, we address these disadvantages through honest communication with our customers about what's possible. We provide detailed design consultations to ensure expectations align with the realities of forged wheel manufacturing. For customers concerned about repair issues, we offer guidance on proper wheel care and maintenance to minimize the risk of damage.

Why Are Forged Wheels So Expensive?

Car owners researching forged wheels experience sticker shock. They see prices several times higher than cast alternatives and question if the difference is justified or just marketing hype.

Forged wheels are expensive due to their resource-intensive manufacturing process, which requires specialized equipment, higher-grade raw materials, extensive machining, rigorous quality control, and skilled labor. The resulting product offers superior strength-to-weight ratio and durability that justify the premium price for performance applications.

Forged wheel manufacturing cost factors](https://treewheels.com/wp-content/uploads/2025/08/5-forged-wheel-manufacturing-cost-factors-water.png)

The price of forged wheels reflects the complex, multi-stage manufacturing process that goes into creating these premium products. Unlike cast wheels, which are made by pouring molten aluminum into molds, forged wheels begin with solid billets of aircraft-grade aluminum that undergo tremendous pressure transformation.

The forging process itself requires specialized equipment that represents a significant capital investment for manufacturers. Hydraulic presses capable of exerting the necessary force (often 8,000-10,000 tons) cost millions of dollars to acquire and maintain. These machines compress aluminum billets under extreme heat and pressure to realign the metal's grain structure, creating a product with superior molecular alignment and strength properties.

Raw materials constitute another major cost factor. Forged wheels use premium aluminum alloys (typically 6061-T6 or 7075-T6) that cost significantly more than the secondary aluminum often used in cast wheels. These aerospace-grade materials provide the foundation for the wheel's strength characteristics.

After the initial forging, extensive CNC machining removes excess material to achieve the final design. This process can take several hours per wheel on sophisticated multi-axis CNC machines operated by skilled technicians. The more complex the design and the lighter the desired final weight, the more machining time required, directly impacting cost.

The comprehensive cost breakdown includes:

| Production Element | Approximate Cost Contribution |

|---|---|

| Raw Materials | 15-20% (premium aluminum alloys) |

| Forging Process | 25-30% (equipment, energy, labor) |

| CNC Machining | 20-25% (equipment time, programming) |

| Finishing | 10-15% (painting, powder coating, polishing) |

| Quality Control | 10-15% (testing, inspection, certification) |

| R&D/Design | 5-10% (engineering, prototyping) |

At Tree Wheels, we maintain transparency about our pricing structure. While our wheels represent a significant investment, we ensure customers understand exactly what they're paying for—superior structural integrity, precision manufacturing, verified performance characteristics, and wheels that are optimized for their specific vehicles and driving needs.

Conclusion

Importing forged wheels from China involves finding trusted manufacturers, clear communication about specifications, and understanding the shipping process. With the right partner, you can access high-quality forged wheels at competitive prices.

Tree Wheels combines advanced forging technology with customer-focused service to deliver premium wheels that exceed expectations.