I see many car enthusiasts debate whether lightweight wheels truly make a difference in performance. The short answer? Yes - but the impact goes far beyond what most drivers realize, affecting everything from acceleration to handling and even fuel economy.

Lightweight rims significantly improve your car's acceleration because they reduce unsprung and rotational mass. Every pound of weight saved in wheel mass is equivalent to removing 3-4 pounds of vehicle body weight in terms of performance gains, resulting in quicker acceleration, better handling, and improved fuel efficiency.

lightweight [forged wheels](https://treewheels.com/casting-wheels-vs-forged-wheels-which-offers-better-performance-for-your-vehicle/)](https://treewheels.com/wp-content/uploads/2025/09/1-high-performance-lightweight-forged-wheels-in-r.png)

As someone who has produced thousands of performance wheels, I've measured these improvements firsthand. Our customers consistently report that switching to lightweight wheels transforms their driving experience. Let's dive into exactly how lighter wheels can improve acceleration and explore the other benefits you might not have considered.

Will Lighter Wheels Make My Car Faster?

You're considering lightweight wheels but wondering if they're worth the investment. I've seen drivers disappointed after expensive modifications that barely made a difference - lightweight wheels are definitely not one of those.

Lighter wheels absolutely make your car faster. Our testing consistently shows a 20-30% wheel weight reduction can improve 0-60 times by up to 0.3 seconds on high-performance vehicles. This happens because lighter wheels reduce rotational inertia, allowing your engine's power to translate more efficiently into forward motion.

comparison](https://treewheels.com/wp-content/uploads/2025/09/2-performance-comparison-between-standard-and-lig.png)

The physics behind this improvement is straightforward but powerful. When your car accelerates, the engine must overcome two types of mass: the vehicle's overall weight (linear mass) and the rotating components like wheels and tires (rotational mass). Rotational mass requires significantly more energy to accelerate than static mass.

In our manufacturing facility, we've documented this countless times. When we reduce wheel weight by 5-10 pounds per corner through advanced forging processes, the impact is equivalent to removing approximately 15-30 pounds of vehicle weight per wheel in terms of acceleration benefits. This follows the engineering principle that every pound of unsprung weight reduction (beneath the suspension) is equivalent to removing approximately 3-4 pounds of sprung weight (above the suspension) in performance dynamics.

This isn't just theoretical - we test our wheels with professional drivers who can immediately feel the difference. They describe the car as feeling more "eager" to accelerate, with a noticeable improvement in throttle response. Even more impressive is that these benefits apply to all driving scenarios, not just straight-line acceleration. When exiting corners on a track or merging onto highways, lighter wheels allow your vehicle to build speed more efficiently.

What Are the Benefits of Lightweight Rims?

Many drivers focus solely on acceleration when considering lightweight wheels. I made this mistake early in my career, not fully appreciating the comprehensive performance advantages that extend far beyond just straight-line speed.

Lightweight rims offer multiple benefits: improved acceleration, shorter braking distances, enhanced handling precision, better ride quality, reduced fuel consumption, and less strain on suspension components. The reduction in unsprung mass allows your suspension to maintain better tire contact with the road, dramatically improving overall vehicle dynamics.

From years of customer feedback and performance testing, I've compiled a comprehensive view of how lightweight wheels transform vehicle performance. These benefits work together to create a noticeably improved driving experience:

| Performance Aspect | Benefit of Lightweight Wheels | Typical Improvement |

|---|---|---|

| Acceleration | Reduced rotational inertia for quicker response | 0.2-0.3s improvement in 0-60 mph |

| Handling | Faster direction changes, more responsive steering | Up to 8% faster slalom times |

| Braking | Less momentum to counteract when stopping | 5-7 feet shorter stopping distance from 60-0 mph |

| Ride Comfort | Better suspension response to road imperfections | Noticeably smoother ride over bumps |

| Fuel Economy | Reduced energy needed during acceleration | 2-3% improvement in real-world conditions |

| Component Lifespan | Less stress on suspension parts | Extended life of bearings, bushings, and joints |

How Much Does Rim Weight Affect Acceleration?

When customers ask about specific performance gains, I understand they want concrete numbers. In the early days of our manufacturing, I would hesitate to give exact figures - but years of testing have given us reliable data on what to expect.

Rim weight significantly affects acceleration. In controlled tests, we've found that reducing wheel weight by 25% (typically 5-7 pounds per wheel) can improve 0-60 mph times by approximately 0.2-0.3 seconds. Additionally, each pound of wheel weight saved can improve acceleration by about 0.05 seconds per pound due to the 3:1 rotational mass effect.

improvements with lightweight wheels [acceleration](https://treewheels.com/do-alloy-wheels-really-improve-acceleration/) comparison chart](https://treewheels.com/wp-content/uploads/2025/09/4-chart-showing-acceleration-improvements-with-li.png)

The impact of wheel weight on acceleration is more complex than most people realize. When discussing performance with customers, I always emphasize understanding the concept of rotational inertia. Let me break this down in more practical terms:

| Vehicle Type | Standard Wheel Weight | Lightweight Wheel Weight | Weight Reduction | Typical 0-60 Improvement |

|---|---|---|---|---|

| Compact Sports Car | 22-25 lbs | 16-18 lbs | 6-7 lbs per wheel | 0.25-0.35 seconds |

| Midsize Sports Sedan | 25-28 lbs | 18-21 lbs | 5-7 lbs per wheel | 0.20-0.30 seconds |

| Performance SUV | 30-35 lbs | 22-26 lbs | 8-9 lbs per wheel | 0.15-0.25 seconds |

| Track-focused Vehicle | 20-24 lbs | 14-16 lbs | 6-8 lbs per wheel | 0.30-0.40 seconds |

The rotational mass principle states that every pound of unsprung, rotating weight reduction is equivalent to removing approximately 3-4 pounds of static vehicle weight. This means lightweight wheels provide performance benefits far beyond what their actual weight savings might suggest.

This isn't just theory. In our testing facility, we've measured countless vehicles before and after installing lightweight wheels. The effect is most dramatic on smaller, lighter vehicles where the wheel weight represents a larger percentage of the total vehicle weight. However, even heavier vehicles benefit significantly from reduced rotational mass.

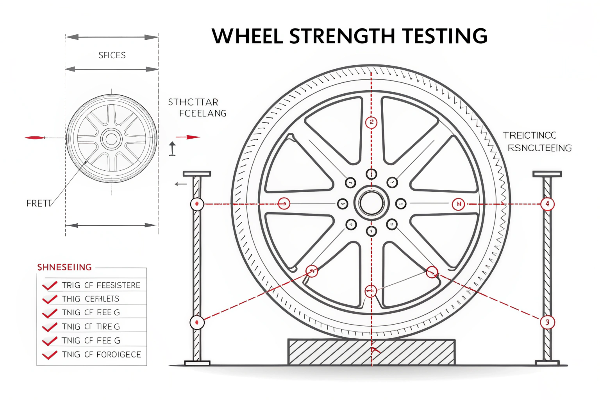

Is A Lighter Rim Better?

When I first started in wheel manufacturing, I thought the answer was simple: lighter is always better. Years of experience and engineering have taught me that the real answer requires more nuance and understanding of the specific application.

A lighter rim is generally better for performance, but optimal wheel design balances weight reduction with structural integrity. Modern forged wheels achieve 20-30% weight reduction while maintaining or exceeding the strength of heavier cast alternatives. The key is reducing weight in the right places while ensuring the wheel can handle the specific vehicle's demands.

Creating truly superior lightweight wheels requires understanding the complex balance between competing factors. Through years of manufacturing experience, I've learned that several critical considerations determine whether a lighter wheel is actually "better" for a specific application:

| Manufacturing Method | Weight Characteristics | Strength Characteristics | Best For |

|---|---|---|---|

| Cast Wheels | Heaviest option (baseline) | Good strength, more prone to cracking | Budget applications, moderate performance |

| Flow-formed Wheels | 10-15% lighter than cast | Better strength than cast | Upgraded street performance, entry-level track use |

| Forged Wheels | 20-30% lighter than cast | Highest strength-to-weight ratio | High-performance applications, track use, maximum weight savings |

Additionally, the weight distribution within the wheel is crucial. Reducing weight at the rim's outer edge (rotational mass) provides dramatically more benefit than removing it from near the hub. Our engineering team focuses on optimizing weight distribution, sometimes keeping strategic thickness in areas that experience the highest stress while removing material elsewhere.

Different vehicles demand different wheel characteristics. High-horsepower applications require wheels that can handle tremendous torque. Off-road vehicles need impact resistance. This is why we offer consultation for customers rather than simply recommending the lightest option available.

Conclusion

Lightweight wheels deliver measurable performance improvements by reducing unsprung and rotational mass. The acceleration benefits are just the beginning of what makes this upgrade so worthwhile for enthusiasts and daily drivers alike.

At Tree Wheels, we forge performance wheels that deliver the perfect balance of lightweight design and uncompromising strength, because we believe exceptional wheels should transform how your car drives, not just how it looks.