Choosing the wrong wheel style can ruin your car's entire aesthetic. Many enthusiasts spend thousands on wheels only to discover they've selected a design that clashes with their vehicle's lines. The confusion between deep dish and concave wheels is particularly common.

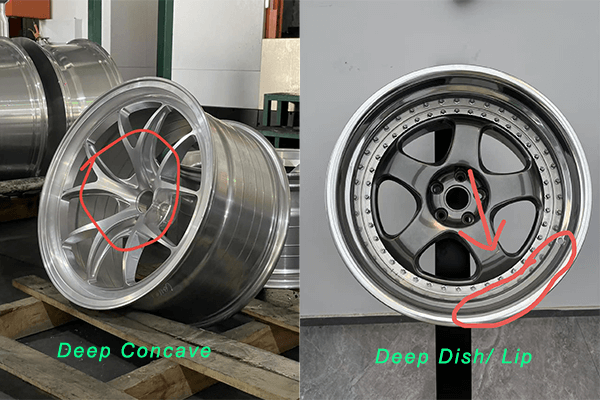

Deep dish and concave wheels are distinctly different designs. Deep dish wheels feature a wide, flat lip extending from the spokes to the edge, creating a "plate-like" appearance. Concave wheels have a curved, inward-sloping face from the lip to the center, giving a three-dimensional, aggressive look.

As a forged wheel manufacturer, I've seen countless customers confuse these terms when placing orders, only to be disappointed when their wheels arrive. This misunderstanding stems from how these terms are often used interchangeably in online forums and social media, despite representing fundamentally different design philosophies. Let's clarify these differences and help you make the right choice for your vehicle.

What Exactly Are Deep Dish Wheels and How Do They Transform Your Car?

The allure of deep dish wheels is undeniable. Their dramatic lip extensions create a vintage, muscular stance that turns heads instantly. But many enthusiasts don't realize how these wheels fundamentally alter a vehicle's appearance and performance.

Deep dish wheels feature a wide, flat lip extending outward from the spoke area, typically 3-4 inches in width. This design creates a "dish" or "plate-like" appearance that adds visual weight to the wheel and produces a classic, often Euro-inspired aesthetic that works particularly well on vintage and luxury vehicles.

In our TreeWheels production facility, we've observed deep dish designs remain particularly popular in the European market segment. The extended lip creates a visual statement that's hard to ignore, especially when paired with polished or chrome finishes that emphasize the dish depth. However, these designs come with practical considerations that many enthusiasts overlook.

The wide lip affects fitment significantly. In fact, we recently worked with a McLaren owner who wanted an extreme deep dish look. To achieve the desired aesthetic, we had to reduce the ET value (offset) to -15, which ultimately caused clearance issues with both the vehicle's body and brake calipers. After several design revisions, we reached a compromise that maintained some of the deep dish look without compromising functionality.

Deep dish designs also typically weigh more than their concave counterparts due to the additional material in the lip area. This weight difference, while seemingly minor, can impact performance metrics like acceleration and braking. Despite these challenges, deep dish wheels continue to command a loyal following among enthusiasts who prioritize classic styling over absolute performance.

For vehicles with adequate clearance, particularly older models with smaller brake packages, deep dish wheels can completely transform the stance. Our Tree Classic series caters specifically to this segment, offering dish depths ranging from 2.5 to 4 inches to accommodate different vehicle types and owner preferences.

How Do Concave Wheels Create That Aggressive, High-Performance Look?

When you see a modern supercar with wheels that seem to draw your eye inward, you're looking at the concave effect. But why has this design become so dominant in performance circles? The answer lies in both aesthetics and engineering.

Concave wheels feature an inward curve from the lip toward the center, creating depth and dimension. Unlike deep dish wheels with their flat extended lips, concave designs create visual drama through inward curvature. This design produces an aggressive, modern aesthetic while often providing improved structural strength and aerodynamics.

Our internal sales data at TreeWheels confirms the growing preference for concave designs, particularly in the North American market where they outsell deep dish designs by approximately 23%. This trend is especially pronounced in the 20-22 inch wheel segment, where visual impact matters tremendously.

The popularity of concave wheels isn't just about looks. Wind tunnel testing we conducted with a racing team partner revealed that moderate concave designs (approximately 25-30mm of concavity) can reduce airflow resistance by about 2.7% compared to flat-faced alternatives. This aerodynamic advantage explains why our Tree Apex series, featuring moderate concave profiles, is particularly popular among track enthusiasts and performance-focused customers.

Concave designs also offer practical benefits regarding brake clearance. The inward curve naturally creates more room for large brake calipers, making them ideal for modern performance vehicles with substantial braking systems. This advantage becomes even more significant as vehicles continue to adopt larger brake packages for improved stopping power.

The manufacturing process for concave wheels presents unique challenges. Creating consistent concavity while maintaining structural integrity requires precise control over the forging process. At our production facility, we utilize specialized dies and multi-stage forming processes to achieve different concavity levels without compromising wheel strength. We classify our concave designs into three categories:

| Concavity Level | Depth Range | Ideal Applications |

|---|---|---|

| Mild Concave | 10-20mm | Luxury sedans, GT cars |

| Medium Concave | 20-35mm | Sports cars, performance sedans |

| Deep Concave | 35mm+ | Supercars, aggressive builds |

Each level offers a distinctly different visual impact, allowing customers to select exactly how dramatic they want their wheel profile to appear.

Can You Combine Deep Dish and Concave Elements for the Ultimate Wheel Design?

Many enthusiasts assume they must choose between deep dish and concave designs, but is this really an either/or decision? The wheel industry has evolved to offer innovative hybrid designs that capture the best of both worlds.

Yes, you can combine deep dish and concave elements through designs like "concave lip" wheels. These feature a moderately wide lip that transitions into a concave face, offering both the dimensional depth of concave wheels and the lip presence of deep dish styles. This hybrid approach has become increasingly popular for those wanting distinctive yet balanced aesthetics.

](https://treewheels.com/wp-content/uploads/2025/10/image-4-concave-lip-wheel-design-create-a-detai.png)

At TreeWheels, we've identified this market gap and successfully developed our "Concave Lip" design series. This approach preserves some width in the lip while incorporating an inward angle to the lip itself. The result is a sophisticated profile that works exceptionally well on Japanese domestic market (JDM) style vehicles and has quickly become our fastest-growing product line.

The technical execution of these hybrid designs requires sophisticated engineering. The transition between the lip and the concave face must be seamless to maintain both structural integrity and visual flow. Our engineers use advanced 3D modeling software to perfect these transitions, ensuring that the final product maintains ideal load ratings while delivering the desired aesthetic.

| Design Type | Manufacturing Complexity | Production Time | Premium Over Standard |

|---|---|---|---|

| Standard One-Piece | 3-4 forming operations | 15-20 days | Baseline |

| Hybrid Concave Lip | 5-7 forming operations | 20-25 days | +15-20% |

| Three-Piece Custom | 9+ forming operations | 30-35 days | +80% |

Manufacturing complexity increases substantially with these hybrid designs. A standard one-piece forged wheel typically requires 3-4 forming operations, while our hybrid designs often demand 5-7 distinct forming steps to achieve the perfect balance between concavity and lip presence. This added complexity is reflected in both production time and cost, with our hybrid designs typically commanding a 15-20% premium over standard designs.

The versatility of these hybrid wheels makes them particularly valuable for enthusiasts with multiple vehicles or those who want a distinctive look without committing fully to either aesthetic extreme. We've found that approximately 35% of our custom wheel clients ultimately select some variation of these hybrid designs after reviewing the full range of options.

For the most discerning clients, our three-piece forged wheel offerings provide the ultimate flexibility. While priced at approximately 1.8 times the cost of our one-piece designs, these wheels offer nearly unlimited customization options in terms of lip depth, concavity, color combinations, and surface treatments. The profit margins on these premium designs are approximately 40% higher than standard offerings, reflecting both their manufacturing complexity and the unique value they provide to customers seeking absolute personalization.

How Do Different Wheel Designs Impact Vehicle Performance and Fitment?

The aesthetics of wheel design often drive purchasing decisions, but the performance implications are equally important. How do these different designs affect your vehicle's handling, fitment, and overall capability?

Wheel design significantly impacts performance beyond aesthetics. Deep dish wheels often require more extreme offsets, potentially affecting handling and steering feel. Concave designs typically offer better brake clearance and may provide slight aerodynamic benefits. Both designs affect unsprung weight differently, with deep concave designs often being lighter than equivalent deep dish versions.

diagram](https://treewheels.com/wp-content/uploads/2025/10/image-5-wheel-fitment-considerations-create-an-.png)

During our decade of manufacturing experience at TreeWheels, we've observed consistent patterns in how wheel design affects practical considerations. Offset management becomes particularly critical with deep dish designs. When a customer requests an extremely deep lip, we often need to use more negative offset values, sometimes approaching -15 as we encountered with our McLaren client. These extreme offsets can alter the scrub radius of the suspension, potentially changing steering feel and response.

Weight distribution within the wheel structure also varies significantly between designs. Deep dish wheels concentrate more mass toward the outer edge of the wheel, which can increase rotational inertia. This physical property can subtly impact acceleration, braking, and suspension response. In contrast, concave designs often distribute weight more evenly or concentrate it closer to the center, potentially offering handling benefits.

Brake clearance remains one of the most critical technical considerations when selecting wheel designs. Modern vehicles with large brake packages often struggle with deep dish designs, as the flat expanse of the dish provides limited room for caliper clearance. This is why we see concave designs dominating in the performance and supercar segments, where substantial braking systems are common.

Our "stepped concave" designs, which we're currently developing for our new Tree Royal series, offer an interesting solution to these challenges. By creating multiple concave transitions within the wheel face, we can maintain adequate brake clearance while still delivering dramatic visual impact. This design approach has seen surging demand in the Middle Eastern market, particularly in Dubai where visual distinction is highly valued.

When consulting with clients, we typically provide comprehensive fitment simulation using their specific vehicle data. This allows us to recommend the maximum lip width or concave depth that can be safely accommodated without compromising functionality. The table below summarizes the typical maximum specifications we recommend for different vehicle classes:

| Vehicle Type | Max Safe Dish Depth | Max Safe Concave Depth | Typical Ideal Offset Range |

|---|---|---|---|

| Compact Sports Cars | 2.0-2.5" | 25-35mm | ET+35 to ET+45 |

| Mid-Size Performance | 2.5-3.0" | 30-40mm | ET+25 to ET+40 |

| Full-Size Luxury | 3.0-3.5" | 20-30mm | ET+15 to ET+35 |

| SUVs/Trucks | 2.0-2.5" | 15-25mm | ET+20 to ET+45 |

These guidelines ensure that our clients receive wheels that not only look exceptional but also maintain proper functionality and performance characteristics.

Conclusion

Understanding the difference between deep dish and concave wheel designs is crucial for selecting the perfect aesthetic for your vehicle. Whether you prefer the classic lip extension of deep dish or the aggressive inward curve of concave designs, TreeWheels offers custom forged solutions that perfectly balance form and function for your unique automotive vision.