Are you struggling with wheel finish decisions? Chinese forged wheel finishes often disappoint buyers due to inconsistent quality. I've faced this problem repeatedly when producing finishes for our customers.

When sourcing forged wheels from China, avoid chrome plating whenever possible and opt for polished finishes instead. Chrome plating in China suffers from quality control issues due to outsourced plating facilities, while high-quality polishing (especially mirror polishing) offers superior durability, consistency, and a beautiful rainbow reflection effect without environmental concerns.

As the founder of Tree Wheels, I've spent years perfecting our wheel production processes. Through many painful lessons with various finishing methods, I've discovered crucial insights that can save you significant headaches and money when ordering custom wheels from China. Let me explain why this matters so much for your wheel investment.

Which is better, chrome or polished wheels?

When investing in custom wheels, choosing between chrome plating and polishing can make or break your satisfaction. I've seen countless customers disappointed after waiting weeks for their chrome-plated wheels.

Polished wheels are superior to chrome wheels when sourcing from China because they offer better quality control, durability, repairability, and environmental benefits. While chrome provides initial shine, polished wheels maintain their appearance longer and can be easily restored if damaged, unlike chrome which peels and cannot be repaired locally.

The real issue with Chinese chrome plating isn't the technology itself but the production ecosystem. In China, wheel manufacturers don't operate their own chrome plating facilities. Due to strict environmental regulations, plating facilities are located in remote areas, completely separated from wheel production. This creates a critical quality control gap.

When we send perfectly manufactured wheels to these third-party plating facilities, we lose direct oversight. Despite working with numerous plating vendors, this disconnected process consistently creates problems. Wheels that leave our factory in perfect condition often return with inconsistent plating thickness, pinholes, or adhesion issues that only become evident weeks later.

In contrast, our polishing processes happen in-house with specialized equipment imported from Japan. This gives us complete quality control from start to finish. Our mirror polishing technology creates an exceptional finish with a distinctive rainbow reflection effect that many customers actually prefer to chrome once they see it in person.

How long does chrome plating last on wheels?

The durability of wheel finishes directly impacts your long-term satisfaction and maintenance costs. I've received countless complaints from customers about premature chrome deterioration.

Chrome plating from Chinese manufacturers typically lasts 1-3 years before showing signs of peeling or bubbling, depending on environmental conditions. In coastal areas or regions using road salt, deterioration can begin within months. Quality polished wheels, however, can maintain their appearance for 5+ years with basic maintenance.

The chrome plating process involves multiple layers: first copper, then nickel, and finally chrome. This complex process creates multiple potential failure points. If any contaminant gets trapped between these layers during the outsourced plating process, it creates weak points where moisture can eventually penetrate.

In my experience overseeing thousands of wheel orders, chrome wheels used in harsh environments inevitably develop problems. Coastal regions with salt air, areas with road salt in winter, or locations with high humidity all accelerate chrome deterioration. When chrome begins failing, it doesn't just dull—it peels and bubbles in unsightly patches that cannot be repaired.

Properly polished wheels face different challenges. While they may oxidize slightly over time, they don't "fail" catastrophically like chrome. More importantly, they can be restored to near-original condition with simple polishing compounds. This means the lifetime value of polished wheels is significantly higher, as they can be refreshed multiple times over many years.

For our customers who absolutely insist on the chrome look, we've developed advanced PVD (Physical Vapor Deposition) finishes as an alternative. While more expensive initially, PVD provides chrome-like appearance with much better durability and environmental benefits.

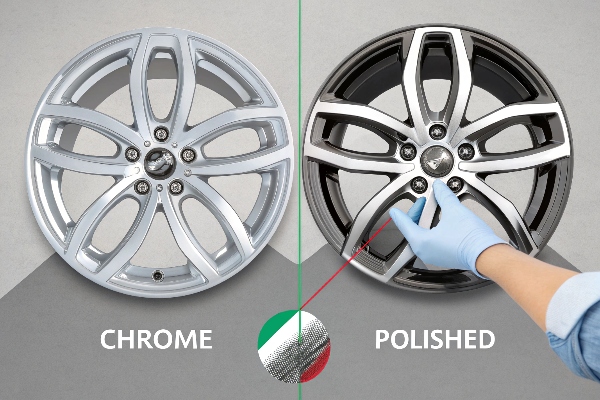

How to tell if something is chrome or polished?

Distinguishing between chrome and polished finishes helps you verify what you're actually receiving. I've had customers unknowingly accept lower-quality options because they couldn't tell the difference.

Chrome plated wheels have a bluish-silver, mirror-like reflection with perfect evenness and depth. Polished wheels appear slightly warmer in tone with a more direct reflection. The simplest test: chrome shows fingerprints easily but wipes clean completely, while polished surfaces briefly retain a ghost of fingerprints even after wiping.

Visual assessment alone can be challenging, especially with today's high-quality polishing techniques. At Tree Wheels, our Japanese polishing equipment achieves a finish so brilliant it creates rainbow reflections that can be mistaken for chrome. However, there are several reliable methods to distinguish between them.

The temperature test is particularly effective – chrome feels noticeably colder to the touch than polished aluminum because of its different thermal conductivity. Another telling difference appears during cleaning: chrome repels most contaminants and wipes completely clean with minimal effort, while polished aluminum may require slightly more attention to restore its full shine.

Understanding these differences becomes crucial when inspecting your wheel order. Chrome's perfect evenness comes at a cost – once damaged, the entire wheel needs replating. Polished wheels might show minor scratches more readily, but these can be buffed out without returning the wheel to a specialized facility.

For professionals and enthusiasts who frequently modify vehicles, recognizing these finish characteristics helps make informed decisions based on the vehicle's use case rather than just initial appearance. Show cars might benefit from chrome's perfect mirror finish for brief displays, while daily drivers and performance vehicles generally fare better with high-quality polished finishes that age more gracefully.

What are the cons of chrome wheels?

Understanding the downsides of chrome wheels helps you make an informed decision that avoids future regrets. After years of customer feedback, I've compiled the real-world disadvantages that aren't mentioned in sales brochures.

Chrome wheels' disadvantages include: 1) Irreparable damage if the plating cracks or peels, requiring complete replacement; 2) Environmental concerns from toxic chemicals used in chrome plating; 3) Weight increase of approximately 3-5% compared to polished wheels; and 4) Significantly higher cost—typically 30-40% more expensive than equivalent polished wheels.

The environmental impact of chrome plating deserves special attention. Traditional hexavalent chromium plating processes used in many Chinese facilities create toxic waste that's extremely difficult to dispose of properly. This is precisely why the Chinese government has isolated these facilities in remote areas with special permits. While some facilities have upgraded to trivalent chromium processes (less harmful but not as durable), many still use older, more damaging methods.

The weight penalty of chrome wheels is particularly relevant for performance applications. The multiple layers of plating materials add noticeable weight, especially on larger wheel faces. This additional unsprung weight negatively impacts acceleration, braking, and handling characteristics. For show cars, this might be acceptable, but for any performance application, it's a significant disadvantage.

Cost considerations extend beyond the initial purchase. When chrome inevitably fails, you can't simply repair it locally like you can with polished wheels. The entire wheel must be stripped and replated at specialized facilities—assuming the underlying wheel hasn't been damaged by corrosion that often occurs under failed plating. This makes the lifetime cost of ownership substantially higher.

At Tree Wheels, we've invested heavily in developing alternative finishes like our mirror polishing technique and PVD coating processes that provide similar aesthetic appeal without these significant drawbacks. Our customers who initially insisted on chrome often become our biggest advocates for polished finishes after experiencing the quality and durability differences firsthand.

Conclusion

Choose polished wheels from Chinese manufacturers for better quality control, durability, and environmental benefits. Chrome might look perfect initially, but polished finishes from specialists like Tree Wheels provide better long-term value and can be maintained for years to come.