Cast vs. forged wheels - a choice that can make or break your driving experience. Many car owners struggle with this decision, unsure which option truly delivers the best performance for their specific needs.

Both cast wheels and forged wheels serve different purposes based on your driving needs. Cast wheels (made from A356-T6 aluminum) are perfect for everyday driving and more affordable ($30-50 each), while forged wheels (made from 6061-T6 aluminum) offer superior strength-to-weight ratios and performance benefits at a higher price ($150-300+).

Casting vs Forged Wheels comparison](https://treewheels.com/wp-content/uploads/2025/07/image-1-casting-vs-forged-wheels-comparison-style.png)

I've been in the wheel manufacturing business for years, and customers constantly ask me about the differences between cast and forged wheels. The mystery surrounding these two manufacturing methods often leaves drivers confused about which option best suits their vehicle. Let me break down everything you need to know about these two wheel types to help you make the right choice.

Which is better, forged or cast wheels?

You're probably wondering if the premium price of forged wheels is worth the investment. The answer depends on what you want from your driving experience and how you use your vehicle day-to-day.

Neither forged nor cast wheels are universally "better" - they serve different needs. Cast wheels are excellent for everyday drivers seeking affordability and reliability, while forged wheels benefit performance enthusiasts and luxury car owners who require enhanced strength, lighter weight, and greater durability.

The difference between these wheel types starts with their materials and manufacturing processes. Our factory specializes in forged wheels, controlling every production step except the initial forging and electroplating to ensure top quality. Though both use aluminum alloys, cast wheels use A356-T6 aluminum while forged wheels use 6061-T6 aluminum.

Think of cast wheels as being made up of countless particles, similar to stone - sturdy but relatively heavy. Forged wheels, meanwhile, consist of aligned metal "fibers" more like bamboo - lighter, more flexible, yet stronger. This fundamental structural difference comes from how they're made. Cast wheels are produced by pouring molten aluminum into a mold, while forged wheels are hammered and pressed from a solid block of aluminum, aligning the metal's grain structure for superior strength.

| Feature | Cast Wheels | Forged Wheels |

|---|---|---|

| Material | A356-T6 Aluminum | 6061-T6 Aluminum |

| Manufacturing Process | Molten aluminum poured into molds | Pressed and hammered from solid aluminum block |

| Internal Structure | Particle-like structure (like stone) | Fiber-like structure (like bamboo) |

| Weight | Heavier | 20-30% lighter |

| Strength | Good for everyday use | Superior strength-to-weight ratio |

| Price Range | $30-50 per wheel | $150-300+ per wheel |

| Best For | Daily drivers, budget-conscious buyers | Performance enthusiasts, luxury vehicles |

For everyday drivers who mainly use highways and city streets, cast wheels represent excellent value and reliability. They handle normal driving conditions without issues and look great on most vehicles. Meanwhile, forged wheels appeal to those modifying their vehicles or driving high-performance cars where every pound matters and strength is paramount.

In our experience, matching wheel type to actual driving needs produces the most satisfied customers. The "better" wheel is simply the one that aligns with your specific requirements and budget.

What are the cons of cast wheels?

When considering wheels for your vehicle, you might worry about the disadvantages of cast wheels. Many enthusiasts claim they're inherently inferior, but is this reputation fully deserved?

Cast wheels' primary disadvantages include being heavier than forged alternatives (affecting acceleration and fuel economy), potentially less impact-resistant in extreme conditions, and having limited customization options. However, modern manufacturing has significantly improved their quality and reliability for everyday use.

Despite exclusively manufacturing forged wheels in our factory, I must acknowledge that today's cast wheels have come a long way. The main drawbacks of cast wheels stem from their manufacturing process. When aluminum is cast into molds, tiny air pockets can form within the metal structure. These microscopic voids can potentially create weak points, especially under extreme stress. This is why cast wheels typically need to be thicker and heavier to achieve sufficient strength.

| Disadvantage | Description | Impact on Driving |

|---|---|---|

| Higher Weight | Cast wheels are typically 20-30% heavier than forged equivalents | Increases unsprung weight, negatively affecting acceleration, fuel economy, and handling |

| Potential Structural Weaknesses | Microscopic air pockets from casting process | Reduced impact resistance in extreme conditions |

| Limited Design Flexibility | Casting has restrictions on complex shapes | Fewer custom design options compared to forged wheels |

| Difficult to Repair | Cast structure doesn't respond well to reshaping | Often requires replacement rather than repair when damaged |

| Heat Dissipation | Less efficient thermal properties | May affect brake performance under extreme conditions |

Weight is perhaps the most significant disadvantage. A heavier wheel increases unsprung weight - the weight not supported by your vehicle's suspension. This extra mass affects handling responsiveness, braking performance, and acceleration. For the average driver, the difference might be barely noticeable, but for performance enthusiasts, every pound matters as it directly impacts how the car feels and performs.

It's worth noting that for developing markets, especially growing automotive sectors in Africa, cast wheels still represent an excellent import opportunity due to their favorable price-performance ratio. Most everyday drivers would never encounter the limitations of cast wheels during normal use, making them a practical choice for many consumers who prioritize value.

Are cast wheels good for racing?

When preparing for race day, you might wonder if your cast wheels will stand up to the intensive demands of competitive driving or if you need to upgrade to forged alternatives.

Cast wheels are generally not ideal for serious racing due to their heavier weight, lesser impact resistance, and potential for failure under extreme racing conditions. Professional racers almost exclusively use forged wheels because the weight reduction significantly improves acceleration, handling precision, and overall performance.

Racing puts extraordinary demands on every vehicle component, with wheels being particularly crucial. In competitive environments, cast wheels encounter several fundamental challenges that limit their suitability. The most significant factor is weight - every unnecessary ounce on a race car translates to reduced acceleration and handling agility. Since cast wheels typically weigh 20-30% more than comparable forged wheels, this creates a measurable performance disadvantage.

| Racing Consideration | Cast Wheels | Forged Wheels |

|---|---|---|

| Weight Impact | Heavier weight reduces acceleration and increases braking distances | Lighter weight improves acceleration, braking, and handling response |

| Structural Integrity | May approach design limits under extreme racing forces | Superior strength handles extreme forces with greater safety margin |

| Heat Management | Less effective heat dissipation | Better thermal properties help maintain brake performance |

| Suspension Response | Slower reaction to surface changes due to higher unsprung weight | Quicker suspension response improves tire contact with road |

| Failure Risk | Higher potential for failure under repeated stress | Lower risk of structural failure during extended racing |

| Suitable Racing Level | Casual track days, amateur events | All racing levels including professional competition |

Racing also subjects wheels to extreme forces that test their structural integrity. The forces encountered during aggressive cornering, sudden direction changes, and hard acceleration/braking can approach or exceed the design limits of cast wheels. Under these conditions, the microscopic voids inherent in the casting process become potential failure points. While modern cast wheels are engineered with significant safety margins for street use, race conditions push beyond typical design parameters.

Temperature management presents another challenge. Racing generates substantial heat through repeated hard braking, which transfers to the wheels. Forged wheels typically dissipate heat more effectively due to their denser molecular structure, helping maintain brake performance throughout extended racing sessions. Cast wheels may be more susceptible to heat-related stress under these extreme conditions.

For casual track days or amateur racing, high-quality cast wheels may suffice, especially those specifically designed with motorsport in mind. However, for competitive racing where fractions of a second matter, the investment in forged wheels typically delivers measurable performance benefits that justify their higher cost.

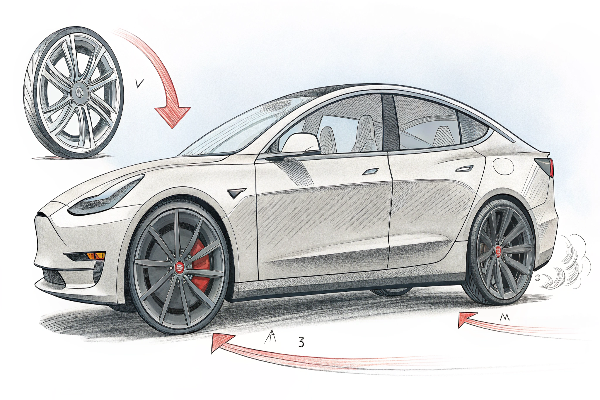

Are Tesla wheels forged or cast?

With Tesla leading the electric vehicle revolution, many owners and enthusiasts wonder about the engineering choices behind their distinctive wheels and whether they use premium forged construction.

Most standard Tesla wheels are high-quality cast aluminum, though some performance models like certain Model S Plaid versions feature forged wheels as options. Tesla often pairs their cast wheels with aerodynamic plastic covers to improve range efficiency, prioritizing the balance between performance, cost, and energy efficiency.

Tesla's approach to wheel design represents a fascinating study in automotive engineering compromise. The company must balance multiple competing factors: energy efficiency, cost, performance, and aesthetic appeal. For most of their production models, Tesla has opted for high-quality cast aluminum wheels that meet their specific requirements.

| Tesla Model | Wheel Type | Special Features | Engineering Priority |

|---|---|---|---|

| Model 3 Standard | Cast Aluminum | Aerodynamic covers | Range efficiency |

| Model Y | Cast Aluminum | Various designs available | Balance of efficiency and style |

| Model S | Primarily cast with forged options | Enhanced design options | Performance with efficiency |

| Model S Plaid (Performance) | Forged options available | Performance-oriented design | Maximum handling and acceleration |

| Model X | Cast Aluminum | Size optimized for SUV weight | Durability and range |

| Cybertruck | Cast Aluminum | Unique design for new model | Durability and distinctive styling |

Tesla's engineering team makes this choice deliberately. For electric vehicles, range efficiency is a paramount concern, and Tesla addresses this partially through aerodynamic optimization. Many Tesla models feature distinctive plastic aerodynamic covers that significantly reduce air turbulence around the wheels, improving overall efficiency. These covers pair with underlying cast wheels to create a system that prioritizes range without sacrificing structural integrity.

The weight penalty of cast wheels is somewhat mitigated in electric vehicles compared to internal combustion cars. Electric motors deliver instant torque without requiring engine revving, making the rotational inertia of wheels less critical for acceleration feel. Additionally, regenerative braking reduces the importance of unsprung weight for braking performance. These factors make the weight disadvantage of cast wheels less significant in Tesla's engineering equation.

For their performance-focused models, particularly special editions of the Model S Plaid, Tesla does offer forged wheel options that reduce weight and improve handling at the expense of range efficiency and cost. These specialized wheels target enthusiasts willing to trade some range for enhanced driving dynamics.

Conclusion

Whether cast or forged wheels are right for you depends entirely on your specific needs and budget. I firmly believe there's no absolute "better" choice - only different solutions for different drivers. As an entrepreneur myself driving a 100,000 RMB Geely for daily commuting, I'm perfectly satisfied with cast wheels. The most suitable wheel is always the one that fits your specific requirements and circumstances. At Tree Wheels, we craft premium forged wheels for enthusiasts seeking that perfect balance of strength, weight, and style, while appreciating that quality cast wheels remain excellent choices for practical daily driving.