Casting WHEELS

Experience the precision and durability of TreeWheels’ casting wheels, engineered for outstanding performance and style. Crafted with advanced technology, our wheels provide superior strength and a variety of customization options. Ideal for automotive enthusiasts and professionals seeking reliability, quality, and unique designs. Enhance your vehicle’s look and performance with TreeWheels’ premium casting wheels.

Custom Casting Wheels

Unlock superior performance with TreeWheels’ casting wheels, designed for strength, precision, and unmatched style. Our wheels are engineered using cutting-edge technology, offering exceptional durability and a wide range of customization options. Perfect for those who demand quality and innovation, TreeWheels delivers the ideal solution for enhancing both the appearance and performance of your vehicle.

Customization options

For You

Colors

Customize wheel colors to match your style—options include glossy, matte, metallic, dual-tone, and custom finishes.

Hubs

Customize wheel hubs with personalized sizes, colors, logos, and finishes to perfectly match your vehicle’s style.

Sizes

Customize wheel sizes to fit your vehicle perfectly, ranging from compact to large diameters, ensuring optimal performance.

rims

Customize rims with unique widths, finishes, colors, and designs to enhance your vehicle’s performance, style, and overall aesthetic appeal.

spokes

Customize wheel spokes tailored to your design, size, and finishes to meet their performance and aesthetic preferences with precision.

Production Progress

STEP 1

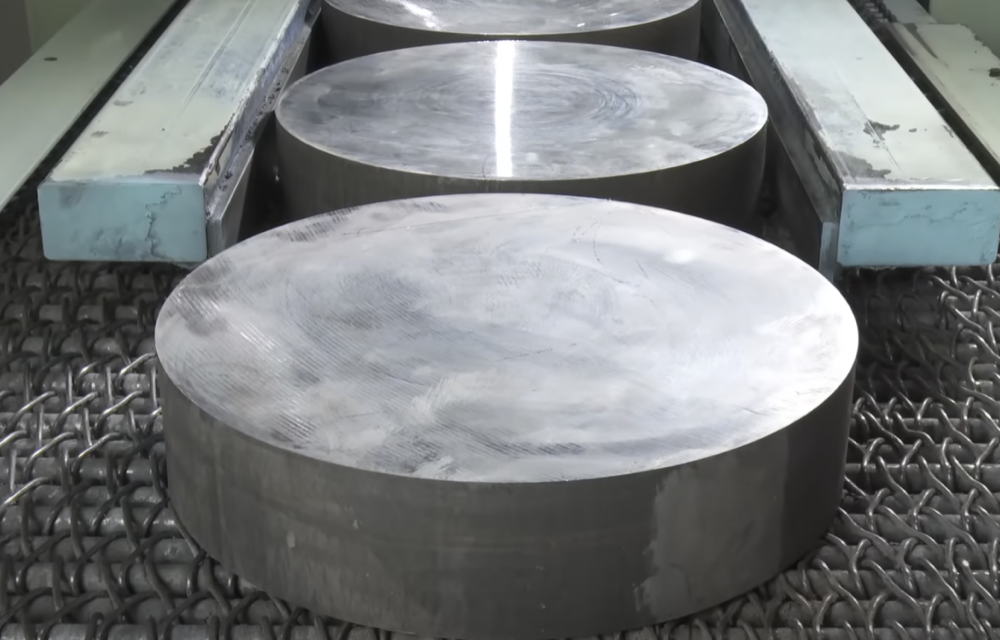

Raw Material Selection (A6061 T6)

Tree Wheels selects high-quality aluminum alloys, ensuring strength, durability, and performance through rigorous material testing and supplier evaluation.

STEP 2

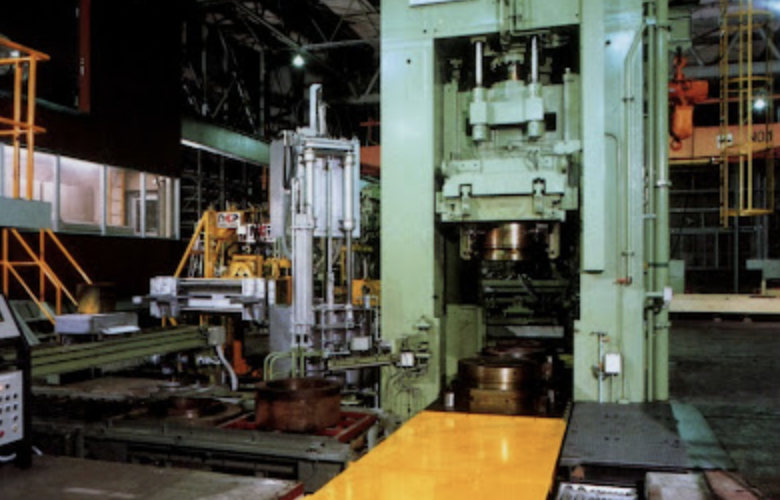

Forging (10,000 Tons)

High-pressure forging or precision casting shapes raw aluminum into wheel blanks, ensuring structural integrity, lightweight design, and enhanced performance.

STEP 3

Heat Treatment (T6)

Wheels undergo controlled heating and cooling cycles to enhance strength, durability, and resistance to stress, ensuring long-lasting performance.

STEP 4

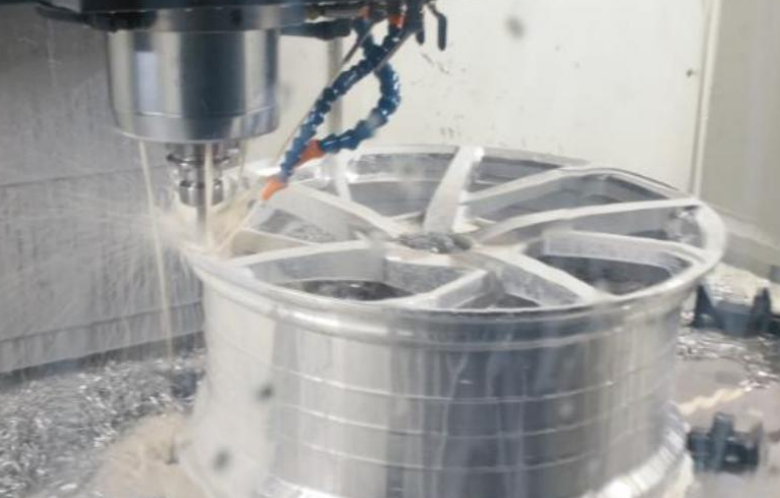

CNC Machining

Advanced CNC machines precisely cut, drill, and refine wheel designs, achieving exact specifications, smooth surfaces, and superior balance.

STEP 5

Surface Finishing

Custom coatings, polishing, painting, and anodizing processes enhance aesthetics, corrosion resistance, and provide various color and texture options.

STEP 6

Quality Inspection

Each wheel undergoes rigorous ISO & DOT-certified testing, including strength, balance, and durability checks to meet international safety standards.

STEP 7

Packaging

Wheels are securely packaged with foam padding and 7-layer corrugated boxes, ensuring protection during transportation and safe delivery.

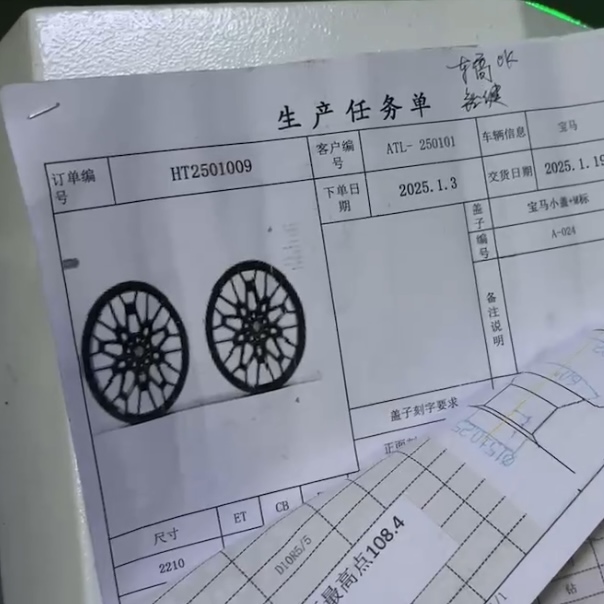

Factory Insight

Top 10 Frequently Asked Questions About Casting Wheels

If you aim to source custom casting wheels for your car, this guide is tailored for you. For specific queries or needs, reach out to Tree Wheels, and let’s navigate your wheel requirements together!

Table of Contents

What are cast wheels and how are they made?

Cast wheels are made by pouring molten aluminum alloy into a mold to shape them. Once the metal cools and solidifies, the wheel is trimmed and drilled to its final form. This method is both efficient and cost-effective, making it a popular choice for producing automotive wheels. There are two main types of casting processes:

- Gravity Casting: Molten metal is poured into a mold by gravity. This process is quicker and cheaper. ⏱️

- Low-Pressure Casting: A slight pressure is applied to the mold, allowing the metal to fill more evenly and reducing air pockets, making it stronger. 💪

Advantages of Cast Wheels:

- Cost-Effective 💸

- High Production Efficiency ⚡

- Variety of Designs 🎨

What are the advantages and disadvantages of cast wheels?

Advantages:

- Affordable 💰: Cast wheels are less expensive to manufacture, offering a more affordable solution for car owners.

- Lightweight 🚗: Cast wheels are lighter than steel wheels, improving fuel efficiency and performance.

- Wide Range of Designs 🛠️: Manufacturers can produce various styles and sizes to suit different vehicles.

Disadvantages:

- Heavier Than Forged Wheels ⚖️: Although lighter than steel, they are still heavier compared to forged wheels, affecting performance in extreme conditions.

- Less Durable 😔: Cast wheels can crack or deform under extreme stress or impact, making them less suitable for high-performance or off-road vehicles.

🛠️ Recommendation: Ideal for daily driving but less suited for extreme conditions like racing or heavy off-road use.

How do cast wheels compare to forged wheels?

| Aspect | Cast Wheels | Forged Wheels |

|---|---|---|

| Weight | Heavier (due to casting process) | Lighter, stronger with better performance 🏎️ |

| Strength | Less strong, can crack under severe impact 💥 | Stronger, more resistant to cracking 🏋️ |

| Cost | Affordable 💸 | Expensive due to intensive manufacturing 💵 |

Detailed Differences:

- Forged wheels are made by compressing solid aluminum, resulting in a much stronger wheel.

- Cast wheels, while affordable, are generally weaker and not as impact-resistant as forged wheels.

⚡ Verdict: Forged wheels are great for high-performance, while cast wheels are perfect for regular use at a more affordable price.

Are cast wheels durable and safe for everyday driving?

Yes, cast wheels are durable and safe for everyday driving. 🚗 They can withstand common road conditions such as potholes, curbs, and bumps. Cast wheels are designed to handle normal street driving without issues. However, they may not be suitable for extreme performance driving like racing or off-road adventures, where high-impact forces might damage them.

🚗 For Regular Use: Cast wheels are a solid choice for commuter vehicles, ensuring both reliable performance and safety.

Why are cast wheels more affordable than forged wheels?

Cast wheels are more affordable because the manufacturing process is simpler and faster compared to forging. 🔨 Forged wheels require more complex processes like heating and pressing the aluminum under high pressure, which involves greater labor and specialized equipment. In contrast, casting is more straightforward, involving the pouring of molten metal into a mold, making it more economical.

💰 Cost Factor: Cast wheels are a more budget-friendly option, while forged wheels come with a higher price due to their superior strength and lightweight properties.

What is the difference between cast wheels and flow-formed wheels?

| Feature | Cast Wheels | Flow-formed Wheels |

|---|---|---|

| Manufacturing Process | Molten metal poured into a mold | Spinning the wheel while still soft to increase strength 🔧 |

| Strength | Good for normal use | Stronger in the rim area 💪 |

| Weight | Heavier | Lighter due to metal shaping 🏎️ |

| Cost | Cheaper | More expensive than cast, cheaper than forged 💵 |

Flow-formed wheels offer improved strength and lighter weight compared to cast wheels due to the additional shaping process. They are stronger than standard cast wheels but still not as light or strong as forged wheels.

⚙️ For Performance: Flow-formed wheels are a great middle ground if you’re looking for a balance between cast and forged wheels.

How do cast aluminum wheels compare to steel wheels?

| Feature | Cast Aluminum Wheels | Steel Wheels |

|---|---|---|

| Weight | Lighter, improving performance and fuel economy 🏎️ | Heavier, reduces performance ⚖️ |

| Strength | Can crack under extreme impact 💥 | More durable but prone to rust 🌧️ |

| Cost | More expensive than steel 💸 | More affordable 💰 |

Cast aluminum wheels are lighter than steel wheels, enhancing your car’s performance, fuel efficiency, and handling. Steel wheels are more durable but are significantly heavier, negatively affecting acceleration and braking.

🚗 For Everyday Driving: Cast wheels improve overall vehicle performance, while steel wheels offer greater durability in harsh conditions but add weight.

Can bent or cracked cast wheels be repaired, or should they be replaced?

Bent Wheels: If a cast wheel is bent (e.g., from hitting a pothole), it can often be repaired by professional services. 🔧 The wheel can be straightened and re-balanced to restore its functionality.

Cracked Wheels: Cracked cast wheels should generally be replaced, as the crack weakens the wheel’s structural integrity. While some cracks may be welded, it’s safer to replace a wheel with a significant crack. ❌

⚠️ Important: If the wheel has a critical crack, it is best to replace it to ensure safety.

What should I consider when buying cast wheels for my car?

| Consideration | What to Look For |

|---|---|

| Fitment | Ensure diameter, width, and bolt pattern match your vehicle 📏 |

| Load Rating | Choose wheels that support the weight of your vehicle ⚖️ |

| Quality & Certifications | Look for reputable brands with safety certifications like TÜV or SAE 🛡️ |

| Design & Performance | Ensure the wheels are aesthetically pleasing and suit your driving style 🎨 |

| Price & Warranty | Compare prices and make sure the wheels come with a warranty for defects 🔒 |

🛠️ Checklist: Before purchasing, confirm that the wheels fit your car’s specifications, meet safety standards, and offer a warranty for protection against defects.

What should businesses consider when sourcing cast wheels from manufacturers?

For businesses sourcing cast wheels, consider the following:

- Manufacturer Reputation: Choose suppliers with a history of producing high-quality wheels. Look for customer reviews or certifications. 🌟

- Certifications & Standards: Ensure the wheels meet international standards such as TÜV, SAE, and other relevant certifications. 🛡️

- Production Capacity: Verify if the manufacturer can handle your order size and provide timely deliveries. ⏳

- Logistics & Support: Check shipping costs, packaging quality, and after-sales support. 🚚

📈 For Business Success: Partner with a reputable manufacturer to ensure quality, reliable service, and compliance with safety standards.

In Summary

Cast wheels offer a cost-effective solution 💸 for daily driving 🚗, with a variety of designs 🎨 and solid performance ⚡. While not as lightweight or strong as forged wheels, they are a practical option for most car owners. Understanding the differences in manufacturing processes 🔧, strength 💪, and price 💰 can help you make the right decision for your needs. Whether you’re looking for a budget-friendly option or a high-performance upgrade 🏎️, cast wheels provide a versatile and reliable choice for everyday use.

Get In Touch

Sample Available