Scratched alloy wheels can destroy the look of even the most beautiful vehicle. I've seen countless customers distressed over curb rash and scrapes on their premium wheels, wondering if their expensive investments are permanently damaged.

Yes, you can polish out scratches from alloy wheels, but success depends on scratch depth and location. Surface scratches affecting only the clear coat can typically be polished out completely, while deeper scratches penetrating the base metal may require more extensive repair methods including filling, repainting, or professional refinishing.

As a manufacturer of high-end forged wheels at Tree Wheels, I've guided many auto shops and modification specialists through wheel repair questions. The good news is that most scratches can be fixed, but understanding the right approach based on damage severity and wheel construction is crucial.

How To Remove Scratches From Alloy Wheels?

Removing scratches from your beautiful alloy wheels feels overwhelming at first. I've seen many DIY attempts go wrong because people don't realize different scratches require different approaches.

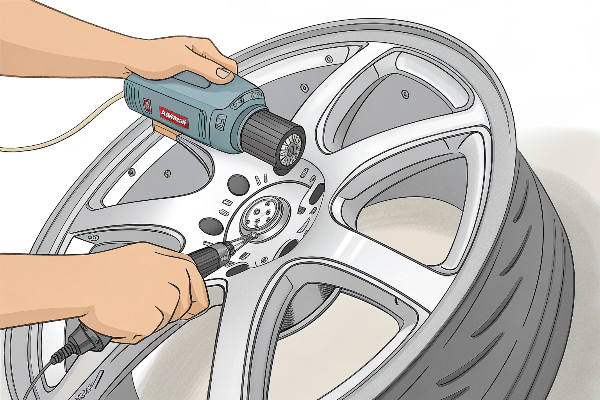

Light surface scratches can be removed through a multi-step process: clean the wheel thoroughly, sand the affected area with progressively finer sandpaper (800-3000 grit), apply polishing compound with a rotary tool, and finish with a sealant. Deep scratches may require filling with putty before sanding and polishing.

I've observed that most wheel damage occurs on specific areas - mainly the front edge of the rim and the spokes. These exposed parts are constantly vulnerable to curbs, road debris, and other hazards. Other areas typically remain protected - inner sections are covered by the tire, and the back connects to bearings and the vehicle axle.

| Wheel Area | Scratch Likelihood | Repair Difficulty | Structural Concern |

|---|---|---|---|

| Rim Edge/Lip | Very High | Moderate | Low to Medium |

| Front Face/Spokes | High | High | Medium to High |

| Inner Barrel | Low | High | Low |

| Hub Mounting Area | Very Low | Very High | Critical |

The repair approach must be tailored to the location of the scratch. For example, scratches on hollow spoke sections require extra caution during polishing. From our manufacturing expertise, I know these areas have lower structural integrity and represent critical stress points in wheel design. Aggressive polishing in these regions can further reduce material thickness and compromise wheel strength.

For light scratches affecting only the clear coat, a fine polish with the right compound often works wonders. However, deeper scratches that reveal the base metal require more intervention. The wheel might need proper preparation, metal filling, careful sanding, and professional refinishing to match the original appearance. At Tree Wheels, we always recommend testing repair techniques on an inconspicuous area first to ensure finish compatibility.

Can Scratched Alloys Be Repaired?

When customers see deep gouges on their expensive alloy wheels, they often assume replacement is inevitable. I've had luxury vehicle owners ready to order complete sets of new wheels over what turned out to be repairable damage.

Yes, even significantly scratched alloy wheels can be professionally repaired in most cases. The repair process depends on the wheel's construction, finish type, and damage severity. Professional wheel repair specialists can restore wheels with filling compounds, precision machining, and custom color matching.

before and after [wheel repair](https://treewheels.com/how-do-i-import-forged-wheels-from-china/)](https://treewheels.com/wp-content/uploads/2025/09/image-3-before-and-after-professional-wheel-repa.png)

Through my years manufacturing forged wheels, I've learned that understanding wheel construction is crucial for proper repairs. Wheels are not just aesthetic components—they're safety-critical parts engineered to precise specifications. This is why repair approaches must consider both appearance and structural integrity.

| Scratch Depth | Repair Method | DIY Feasibility | Post-Repair Testing Needed |

|---|---|---|---|

| Clear Coat Only | Polishing | High | No |

| Light Metal Scratch | Sand & Polish | Medium | No |

| Deep Metal Gouge | Fill & Refinish | Low | Yes (for structural areas) |

| Structural Damage | Professional Repair/Replace | Not Recommended | Critical (FEA Analysis) |

When assessing repairability, we first determine if the damage affects load-bearing areas. Deep scratches near mounting points, lug holes, or load-bearing spokes present more concerns than superficial rim edge damage. In our factory, we use advanced stress analysis to design wheels with appropriate material distribution, ensuring durability even with minor cosmetic damage.

For high-end custom wheels like the ones we produce at Tree Wheels, repairs should always maintain the original finish quality. Different wheel finishes—machined faces, diamond-cut details, custom powder coating, or specialized anodizing—each require specific repair techniques. This is why we typically recommend professional wheel repair specialists who understand the nuances of different alloys and finishes.

Most importantly, any significant repair that includes material removal through machining or aggressive polishing should be followed by structural verification. In our manufacturing facility, we conduct FEA (Finite Element Analysis) strength testing on wheel designs to ensure they meet load requirements. Similar principles apply after repairs—the wheel's structural integrity should never be compromised for cosmetic improvements.

Can A Scratch On A Rim Be Buffed Out?

That moment when you scrape your wheel against a curb creates instant panic. I've experienced firsthand the sinking feeling, wondering if a simple buffing can make the damage disappear.

Minor scratches on wheel rims can often be buffed out using polishing compounds and a buffing wheel attachment on a rotary tool. However, success depends on scratch depth—if it's only in the clear coat, buffing works well; if it penetrates the metal or affects painted/coated surfaces, additional steps beyond buffing will be necessary.

From my manufacturing perspective at Tree Wheels, I can tell you that rim edges are actually designed with some cosmetic damage in mind. The outer lip of most wheels has additional material thickness compared to other sections, making it more suitable for buffing and light machining during repairs.

| Buffing Tool | Best For | Technique | Caution Areas |

|---|---|---|---|

| Hand Polish | Very Light Scratches | Circular Motion | Time-consuming |

| Drill Attachment | Light to Medium Scratches | Low RPM, Light Pressure | Heat Buildup |

| Rotary Buffer | Medium Scratches | Progressive Compounds | Edge Rounding |

| Angle Grinder | Deep Scratches (Pro Use) | Precision Control | Material Removal |

When buffing a scratched rim, understanding the wheel's finish is crucial. Some wheels have painted surfaces with clear coat protection, others have machined faces with anodized finishes, and high-end wheels might have complex multi-stage finishes. Each requires a different buffing approach and compound selection.

The buffing process typically starts with cleaning and degreasing the damaged area. For light scratches, a medium polishing compound applied with a buffing wheel attachment on a rotary tool often delivers good results. Deeper scratches require starting with more aggressive compounds and progressively moving to finer ones for the final finish.

What many people don't realize is that buffing removes a microscopic layer of material. On structural areas like thin spokes or complex wheel designs, this material removal must be carefully controlled. In our factory production, we specify thickness tolerances for each section of the wheel based on stress analysis. This same principle applies to repairs—buffing should never remove so much material that it compromises the wheel's load-bearing capacity, especially in structurally critical areas.

How To Discreetly Fix Scratched Alloy?

Visible wheel repairs can be just as distracting as the original damage. Many of my customers who own luxury vehicles seek undetectable repairs that preserve their wheels' premium appearance.

For discreet alloy wheel repairs, use touch-up paint pens matched to your wheel color for small scratches. For larger damages, consider mobile wheel repair services that specialize in on-site repairs using professional-grade fillers, primers, color-matching technology, and clear coat application that blends seamlessly with the original finish.

technique discreet [wheel repair](https://treewheels.com/how-do-i-import-forged-wheels-from-china/)](https://treewheels.com/wp-content/uploads/2025/09/image-5-close-up-of-discreet-wheel-repair-techni.png)

Through my experience at Tree Wheels, I've found that the key to invisible repairs lies in understanding the wheel's original manufacturing process. Each wheel finish has specific characteristics that must be replicated during repair. For instance, machined-face wheels have a distinctive pattern created by the cutting tool that's challenging to match with hand polishing.

| Wheel Finish Type | Repair Difficulty | Best Repair Approach | Discreet Fix Success Rate |

|---|---|---|---|

| Polished Aluminum | Medium | Progressive Polishing | High |

| Painted/Powder Coated | Medium | Color Match & Blend | High |

| Diamond Cut/Machined | Very High | Professional CNC | Medium |

| Anodized | High | Specialized Treatment | Medium |

| Chrome | Very High | Professional Replating | Low |

Location-specific approaches are essential for discreet repairs. Damage on the rim edge often allows for more aggressive treatment since this area is less visible. Scratches on the face or spokes—especially on wheels with complex designs—require more finesse and precision matching. I always remind our clients that the most exposed sections of a wheel are also typically the most structurally sensitive, like hollow spokes or decorative details.

For the most discreet repairs, color matching is crucial. Many professional wheel repair specialists use spectrophotometers to analyze the exact color and sheen of your wheel's finish. This technology allows them to create custom-mixed paint that precisely matches your wheel, even accounting for age-related changes in the original finish.

Some repair techniques actually integrate the repair into the wheel's design. For example, on machined-face wheels with spoke damage, a skilled technician might slightly refinish the entire spoke to ensure uniform appearance rather than just spot-treating the scratched area. At Tree Wheels, we sometimes recommend complete refinishing of the wheel face for severe damage, as this provides the most consistent appearance while ensuring structural integrity through careful material management.

Conclusion

Most alloy wheel scratches can be successfully repaired, from simple buffing for light surface scratches to professional restoration for deeper damage. Always consider both aesthetics and structural integrity during repairs.

For truly exceptional wheels that combine strength, beauty, and durability, Tree Wheels delivers custom forged excellence for discerning enthusiasts worldwide.