I often hear customers frustrated with limited wheel options. Most struggle to find designs that perfectly match their vision for their vehicle, settling for mass-produced alternatives that don't quite deliver.

Yes, you can design your own custom forged wheels. The process typically begins with your concept or reference images, followed by professional design rendering, engineering validation, and manufacturing. Most forged wheel manufacturers offer customization services with varying degrees of personalization options.

At Tree Wheels, we believe your vehicle deserves wheels that are as unique as you are. Custom forged wheels aren't just about standing out—they're about expressing your personal style while ensuring perfect fitment and performance for your specific vehicle.

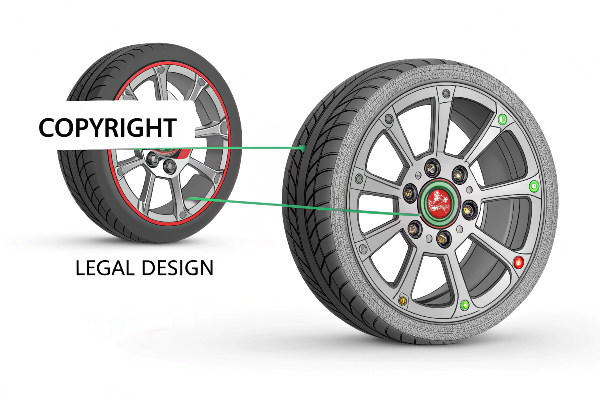

Are Wheel Designs Copyrighted?

Many wheel enthusiasts worry about legal implications when requesting designs similar to popular styles. This concern often prevents them from pursuing their ideal wheel aesthetics.

Wheel designs typically have limited copyright protection. While the overall design concept cannot be copyrighted, specific artistic elements and brand logos are protected. Minor modifications to existing designs are generally acceptable, but directly copying unique design features or using another company's branding is legally problematic.

In my years of manufacturing wheels, I've found that design patents in the wheel industry offer minimal protection. The reality is that slight modifications to a design—changing spoke patterns by a few millimeters or adjusting angles slightly—create legally distinct products.

This is why you'll see many wheels across different brands with remarkably similar appearances. However, there's a clear line that responsible manufacturers won't cross: brand infringement. While we can create a wheel with design inspiration from various sources, we never reproduce another company's logos or branding.

For our clients, this means tremendous design freedom. If you admire certain aesthetic elements from various wheels, we can incorporate similar styles into your custom design while ensuring it remains legally distinct and tailored to your specific requirements. Our design team excels at creating wheels that capture desired aesthetics while adding unique touches that make them exclusively yours.

Design Protection in the Wheel Industry

| Protection Type | Coverage | Limitations |

|---|---|---|

| Design Patents | Specific unique features | Easily circumvented with minor changes |

| Trademarks | Brand names, logos | Strong protection, cannot be used by others |

| Copyright | Artistic elements | Limited application to functional items |

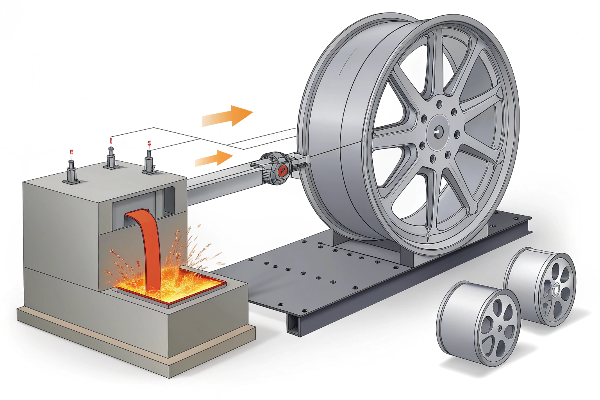

How Do You Make Forged Wheels?

Car enthusiasts often wonder about the mysterious process behind creating high-performance wheels. Many assume all wheels are made the same way, missing the critical distinctions.

Forged wheels are made by applying extreme pressure to heat-treated aluminum billets. This compression aligns the metal's grain structure, creating stronger molecular bonds. The compressed billet is then machined to the final wheel design, resulting in a product that's stronger yet lighter than cast alternatives.

At Tree Wheels, our forging process represents the pinnacle of wheel manufacturing technology. We begin with premium 6061-T6 aluminum billets, selected for optimal strength-to-weight characteristics. These solid metal cylinders undergo intense heating to approximately 480°C (900°F) before entering our 10,000-ton hydraulic press.

This massive pressure transforms the molecular structure of the aluminum, aligning the grain direction and eliminating microscopic gaps or weaknesses. The result is a dense, compressed metal blank with significantly enhanced structural properties compared to cast alternatives.

After forging, we employ 5-axis CNC machines for precision cutting. This advanced equipment allows us to create incredibly detailed designs with tolerances measured in hundredths of a millimeter. Our engineers carefully balance material removal to maintain structural integrity while achieving the desired aesthetic and weight reduction.

Each wheel undergoes multiple machining phases, gradually transforming from a simple forged blank into a precisely engineered wheel. We can create virtually any design, from classic multi-spoke patterns to complex mesh designs or minimalist modern styles, all without compromising the strength inherent to the forging process.

Forging Process Comparison

| Process Stage | One-Piece Forged | Two-Piece Forged | Three-Piece Forged |

|---|---|---|---|

| Production Time | 15-20 days | 20-25 days | 30-35 days |

| Customization Level | Moderate | High | Extensive |

| Weight Optimization | Excellent | Very Good | Good |

| Design Flexibility | Limited by single piece | Better than one-piece | Maximum flexibility |

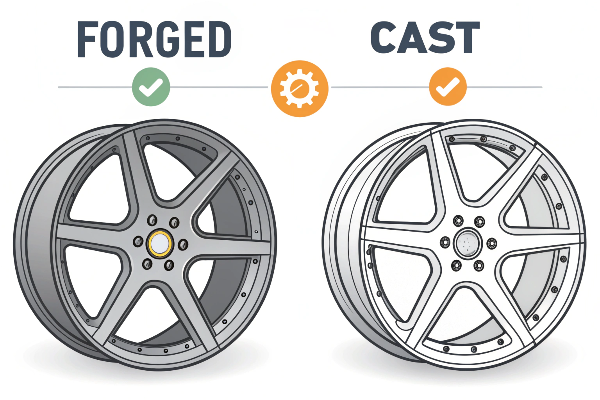

What Are The Disadvantages Of Forged Wheels?

People considering wheel upgrades often hesitate due to the significant price difference between forged and cast options. They wonder if the performance benefits truly justify spending two to four times more.

The main disadvantages of forged wheels are higher cost, limited design flexibility compared to cast wheels, longer production times, and potentially more expensive repairs. While they offer superior performance characteristics, these drawbacks make them less practical for some applications where cast wheels provide adequate performance.

Having manufactured both forged and cast wheels, I can offer a balanced perspective on the limitations of forged wheels. The most obvious disadvantage is cost—our forging process requires specialized equipment, highly skilled technicians, and significantly more time per wheel compared to casting methods.

The initial investment in forging equipment alone exceeds millions of dollars, and the process consumes substantial energy. Additionally, more material is wasted during production as we machine away significant portions of the forged blank to achieve the final design. These factors necessarily translate to higher prices for consumers.

Design limitations also exist with forged wheels, particularly with one-piece forged options. The manufacturing process restricts certain complex aesthetic features that are easily achieved with casting. While our multi-piece forged wheels overcome many of these limitations, they introduce additional complexity and cost.

Production lead times represent another consideration. While cast wheels can often be mass-produced quickly, even our most efficient forging operations require 15-20 days for one-piece designs, with multi-piece options extending to 30-35 days. For customers requiring immediate solutions, this timeline may prove problematic.

Forged Wheel Limitations

| Limitation | Impact | Our Solution |

|---|---|---|

| Higher Cost | 2-4x price of cast wheels | Optimized production efficiency |

| Design Restrictions | Less intricate designs in one-piece | Multi-piece options for complex designs |

| Production Timeline | 15-35 days depending on type | Transparent scheduling and updates |

| Repair Complexity | More specialized repair requirements | Warranty coverage and repair guidance |

Do Forged Wheels Crack Or Bend?

Car enthusiasts with damaged wheels often ask me if investing in forged wheels will eliminate their problems. They've experienced cracked cast wheels and hope forged options might be indestructible.

Forged wheels can crack or bend under extreme impact, but they're significantly more resistant to damage than cast wheels. Their aligned grain structure allows them to flex slightly before failing, unlike cast wheels which may shatter. When properly engineered, forged wheels typically bend rather than crack, often remaining repairable.

In my experience overseeing quality testing at Tree Wheels, I've gained considerable insight into how forged wheels respond to impact. We regularly conduct controlled impact tests that simulate real-world scenarios like pothole strikes or curb impacts. The results consistently demonstrate the superior damage resistance of forged construction.

The fundamental difference lies in the metal's molecular structure. During the forging process, extreme pressure aligns the aluminum's grain structure uniformly throughout the wheel. This creates a product that can actually flex slightly under impact—absorbing energy rather than immediately failing. Cast wheels, by contrast, have a more random grain structure with potential air pockets that create natural failure points.

When a forged wheel does eventually fail under extreme circumstances, it typically bends rather than shatters. This characteristic often means the wheel remains repairable and, more importantly, reduces the risk of catastrophic failure while driving. I've seen forged wheels take impacts that would obliterate cast alternatives, yet remain structurally sound enough to keep the vehicle controllable.

However, it's important to understand that "stronger" doesn't mean "indestructible." Even the finest forged wheels have physical limits. Factors like wheel width, offset, design complexity, and especially weight all influence durability. A lightweight forged racing wheel prioritizing minimal rotational mass will necessarily sacrifice some impact resistance compared to a forged off-road wheel designed for durability.

Impact Response Comparison

| Impact Type | Typical Cast Wheel Response | Typical Forged Wheel Response |

|---|---|---|

| Minor Pothole | Possible crack development | Usually unaffected |

| Moderate Curb Strike | Edge damage, possible crack | Minor cosmetic damage only |

| Severe Impact | Likely to crack or shatter | May bend but rarely catastrophic failure |

| Repairability | Often requires replacement | Frequently repairable if bent |

Conclusion

Custom forged wheels offer unparalleled personalization with superior strength and performance despite higher costs and longer production times. When designed properly, they provide the perfect balance of style, strength and function. At Tree Wheels, we bring your unique wheel vision to life with sincerity above all.