You've seen the price tags - forged wheels can cost 5-10 times more than cast wheels. The sticker shock might have you questioning whether they're worth the investment or just another overpriced car accessory.

Forged wheels are worth the money for performance vehicles and custom builds. They offer significant weight reduction (20-25% lighter than cast wheels), superior strength, enhanced performance, and customization options that justify their premium price for enthusiasts seeking the best driving experience.

I believe you get what you pay for. If forged wheels weren't worth their premium price, they wouldn't maintain their market position year after year. Let's explore what makes these wheels special and whether they're the right choice for your vehicle.

What Are the Disadvantages of Forged Wheels?

The price tag on forged wheels can cause serious sticker shock. Many car enthusiasts find themselves wondering if the disadvantages outweigh the benefits when looking at wheels that cost several times more than standard options.

The main disadvantages of forged wheels are their high cost (often $3,000-$5,000+ per set), limited availability, longer production times (3-5 weeks for custom orders), and overkill performance capabilities for everyday driving. They're also more expensive to repair if damaged.

Let's break down these disadvantages in more detail to help you make an informed decision:

Cost Analysis: Are They Worth The Premium?

The cost factor is the most obvious drawback. For the price of one set of forged wheels, you could purchase multiple sets of cast wheels. Here's a comparative breakdown:

| Wheel Type | Average Cost (Set of 4) | Relative Cost |

|---|---|---|

| Cast Wheels | $600-$1,200 | Baseline |

| Flow-Formed | $1,200-$2,500 | 2-3x Cast |

| Forged Wheels | $3,000-$8,000+ | 5-10x Cast |

This price difference means you need to carefully consider your needs. For my own car, a Geely Boyue L, I've stuck with the factory-installed cast wheels. There's no shame in this - they perfectly suit my daily driving needs and the performance level of my vehicle.

Production Limitations

Another disadvantage is the longer lead time for production. While mass-produced cast wheels are readily available, forged wheels often require:

- 15-20 days for one-piece designs

- 20-25 days for two-piece designs

- 30-35 days for three-piece custom designs

This waiting period can be frustrating if you're eager to upgrade your vehicle quickly or need a replacement wheel in a hurry.

Do Forged Wheels Make a Difference?

I've heard many car enthusiasts debate whether forged wheels actually deliver noticeable improvements. Some dismiss them as expensive accessories that only look good on paper or in showrooms.

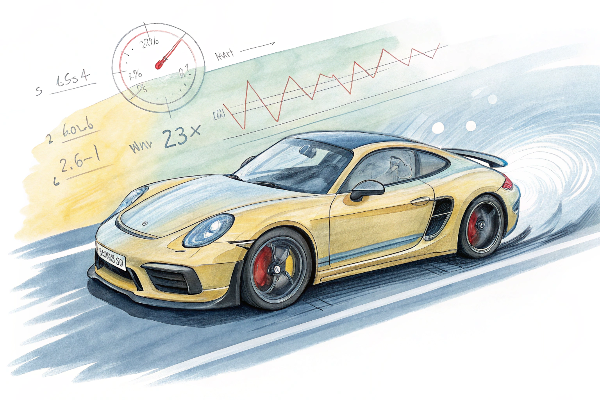

Forged wheels make a measurable difference in vehicle performance by reducing unsprung weight by 20-25%, improving acceleration (0.2-0.3 seconds faster 0-60 mph), enhancing braking distance (5-10 feet shorter from 60-0 mph), and providing better handling through increased rigidity and responsiveness.

When we look deeper at the performance benefits, the value of forged wheels becomes clearer, especially for certain types of drivers and vehicles:

Performance Metrics: The Numbers Don't Lie

The performance advantages of forged wheels are measurable and significant:

| Performance Aspect | Improvement with Forged Wheels | Why It Matters |

|---|---|---|

| Weight Reduction | 20-25% lighter than cast wheels | Less rotational mass |

| Acceleration | 0.2-0.3 seconds faster (0-60 mph) | Quicker response |

| Braking | 5-10 feet shorter stopping distance | Enhanced safety |

| Fuel Efficiency | 1-2% improvement | Long-term savings |

These benefits come from the manufacturing process itself. During forging, aluminum is compressed under enormous pressure (up to 13,000 tons), aligning the metal's grain structure and eliminating internal voids. This creates a wheel that's not only lighter but also has a much higher tensile strength.

For track day enthusiasts, these improvements can mean the difference between setting a personal best or not. For performance car owners, they enhance the overall driving experience by making the vehicle more responsive and connected to the road. However, for my Geely Boyue L and similar everyday vehicles, these advantages would be barely noticeable during normal driving conditions.

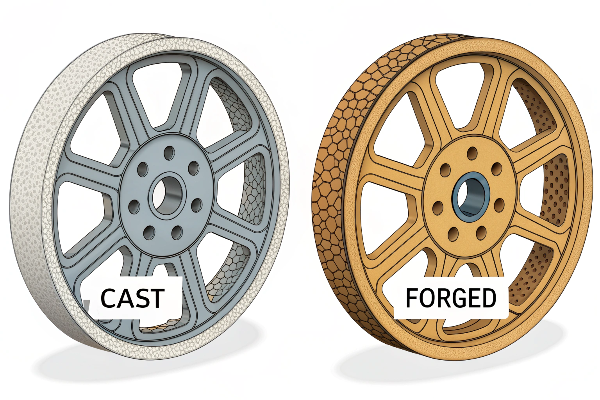

Which Is Better, Cast or Forged Wheels?

When shopping for wheels, I'm often confronted with this fundamental choice: cast or forged? The price difference is substantial, making me wonder if forged wheels are truly superior or just marketing hype.

Forged wheels are objectively better in terms of strength-to-weight ratio, offering 20-25% weight reduction while maintaining superior structural integrity. However, cast wheels provide better value for daily drivers and non-performance vehicles where the benefits of forged construction would be largely unnoticeable.

Let's examine the differences between these manufacturing processes and how they affect the final product:

Manufacturing Process Comparison

Understanding how each type of wheel is made helps explain their different properties:

| Feature | Cast Wheels | Forged Wheels |

|---|---|---|

| Manufacturing Method | Molten aluminum poured into molds | Solid aluminum compressed under pressure |

| Material Structure | Random grain pattern, may have air pockets | Aligned grain structure, dense material |

| Customization | Limited by mold designs | Highly customizable (offsets, widths, designs) |

| Production Speed | Faster, mass production friendly | Slower, more labor-intensive |

| Weight | Heavier (benchmark) | 20-25% lighter |

The manufacturing difference creates wheels with fundamentally different characteristics. Cast wheels are produced by pouring molten aluminum into a mold, while forged wheels are made by applying extreme pressure to solid aluminum blocks, compressing the molecular structure.

For maximum visual impact and customization options, forged wheels offer advantages that cast wheels can't match. They can be made with more aggressive designs like deeper lips and concave faces without compromising structural integrity. This is why many modified cars and luxury vehicles feature forged wheels – they allow for more dramatic styling while maintaining or improving performance.

I've chosen to keep the cast wheels on my Geely Boyue L because they're perfectly suitable for daily driving. The performance benefits of forged wheels would be minimal for my driving style and vehicle type, making the extra investment unnecessary. There's absolutely nothing embarrassing about using quality cast wheels on a daily driver – it's actually the sensible choice.

Do Forged Wheels Crack or Bend?

When investing in premium wheels, durability becomes a major concern. I've heard horror stories about expensive wheels being damaged beyond repair after hitting a pothole. This begs the question: are forged wheels actually more durable?

Forged wheels rarely crack but can bend under extreme impact. Their aligned grain structure allows them to flex and absorb energy rather than shattering like cast wheels. When damaged, forged wheels can often be repaired rather than replaced, as they typically bend before breaking.

demonstration](https://treewheels.com/wp-content/uploads/2025/08/5-forged-wheel-durability-test-create-a-realisti.png)

Let's explore the durability aspects of forged wheels in more depth:

Impact Response: Bend vs. Break

The molecular structure of forged wheels gives them unique properties when faced with impacts:

| Impact Scenario | Cast Wheel Response | Forged Wheel Response |

|---|---|---|

| Minor Pothole | May develop hairline cracks | Typically no damage |

| Major Pothole | Likely to crack or shatter | May bend but rarely cracks |

| Severe Impact | Complete failure/shattering | Potential bending, possible to repair |

| Repeated Stress | Fatigue cracks develop | Maintains structural integrity longer |

This difference in impact response comes from the manufacturing process. During forging, the aluminum's grain structure becomes aligned and compressed, eliminating weak points and air pockets. This creates a more ductile material that can flex under stress instead of breaking.

For track use or driving on rough roads, this durability difference becomes significant. A cast wheel that hits a pothole might crack and be rendered unusable, requiring complete replacement. In contrast, a forged wheel might sustain a bend that can be repaired by a professional wheel repair service.

The repair process for forged wheels typically costs between $150-$300 per wheel, which is substantial but still less than replacing an expensive forged wheel outright. This repairability factor adds to the long-term value proposition of forged wheels for those who drive in challenging conditions or participate in track days where wheel damage is more likely.

For everyday driving on well-maintained roads with a vehicle like my Geely Boyue L, the durability advantages of forged wheels become less relevant. The factory-installed cast wheels are designed to handle normal driving conditions with plenty of safety margin, making forged wheels an unnecessary upgrade for this use case.

Conclusion

Forged wheels are worth the investment for performance vehicles and enthusiasts seeking the best in strength, weight, and customization. For everyday drivers like me with my Geely Boyue L, quality cast wheels are perfectly sufficient. Tree Wheels offers premium forged options for those who demand nothing but the best for their automotive passion.