Driving a high-performance vehicle but worried about wheel durability? You've likely encountered the forged versus cast wheel debate. The difference isn't just marketing—it's metallurgy, affecting your car's performance, safety, and handling in ways you might not realize.

Forged wheels are significantly stronger than cast wheels because they're manufactured using intense pressure that aligns the metal's grain structure. This creates a denser, more uniform material without the microscopic air pockets common in cast wheels, resulting in wheels that are approximately 300% stronger yet 25-40% lighter.

](https://treewheels.com/wp-content/uploads/2025/09/image-1-forged-vs-cast-wheel-structure-style-inf.png)

I've been in the wheel manufacturing business since founding Tree Wheels, and I've seen countless examples of how wheel construction affects performance. The science is clear, but the implications for your driving experience are what really matter. Let's explore why the forging process creates superior wheels and what that means for your vehicle.

Are Forged Or Cast Wheels Stronger?

When customers ask me this question at trade shows, my answer is always definitive: forged wheels significantly outperform cast wheels in strength tests. The evidence isn't just in laboratory testing—it's visible under a microscope and proven on racetracks worldwide.

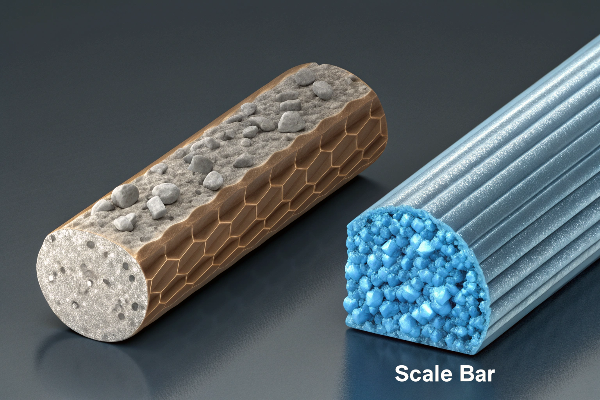

Forged wheels are substantially stronger than cast wheels because of their internal structure. Imagine forged wheels having a bamboo-like fibrous internal structure that provides exceptional resilience, while cast wheels have a structure more like small pebbles clustered together—sturdy but lacking flexibility and carrying extra weight.

In our production facility, we start with solid billets of aircraft-grade aluminum. These billets undergo enormous pressure—up to 10,000 tons—that literally forces the aluminum molecules into perfect alignment. This creates the fibrous, aligned grain structure I mentioned. Looking at cross-sections under a microscope reveals this dramatic difference: forged wheels show tight, directional grain patterns similar to bamboo fibers, while cast wheels display a more random, granular structure like small stones.

| Feature | Forged Wheels | Cast Wheels |

|---|---|---|

| Internal Structure | Bamboo-like fibrous structure | Pebble-like granular structure |

| Molecular Alignment | Highly aligned, directional | Random, inconsistent |

| Density | Higher density, fewer air pockets | Lower density, more air pockets |

| Weight | 25-40% lighter | Heavier for comparable strength |

| Impact Response | Can flex slightly without breaking | More prone to crack under impact |

This structural difference directly impacts performance. When a forged wheel encounters an impact, the aligned grain structure allows it to flex slightly without breaking—much like how bamboo can bend in strong winds without snapping. Cast wheels, with their less cohesive internal structure, are more prone to crack under similar impacts.

I've seen this countless times when working with modification shops across the USA and Dubai. Cast wheels often crack or completely break under conditions that our forged wheels easily withstand. This isn't theoretical—it's the practical reality of physics and metallurgy at work in real-world driving conditions.

What Type Of Wheels Are The Strongest?

In my years producing wheels for high-performance vehicles, I've learned that not all forged wheels offer the same level of strength. There's actually a hierarchy of strength that serious drivers should understand before investing.

One-piece forged monoblock wheels represent the strongest wheel configuration available. Their unified construction eliminates weak points entirely, while multi-piece forged wheels offer excellent strength with added style flexibility. Flow-formed wheels (a hybrid technology) sit between forged and cast in the strength spectrum.

The manufacturing method determines wheel strength more than any other factor. At Tree Wheels, our one-piece forged monoblock wheels undergo the most intensive production process. We apply enormous pressure to a single piece of aluminum, creating a seamless component with perfectly aligned grain structure throughout. This results in maximum strength because there are no joints, bolts, or welds to create potential failure points.

| Wheel Type | Manufacturing Process | Strength Rating | Weight | Best For |

|---|---|---|---|---|

| One-Piece Forged | Single aluminum billet, extreme pressure | Excellent | Lightest | Racing, high-performance applications |

| Two-Piece Forged | Forged center, separate rim | Very Good | Light | Performance with style customization |

| Three-Piece Forged | Forged center, separate rim sections | Good | Light to Medium | Maximum customization options |

| Flow-Formed | Cast center, spun/formed barrel | Moderate | Medium | Mid-level performance upgrade |

| High-Quality Cast | Premium casting techniques | Fair | Heavy | Daily driving, entry-level |

| Standard Cast | Basic gravity casting | Basic | Heaviest | Economy applications |

Our two-piece and three-piece forged wheels maintain much of this strength while allowing for more customization options. The forged centers retain the bamboo-like fibrous structure that provides exceptional strength, though the connection points between pieces can never be quite as strong as a monoblock design.

Below forged wheels, you'll find flow-formed (sometimes called rotary-forged) wheels, which start as cast wheels but undergo a secondary process that stretches and compresses the barrel, creating a semi-forged structure. While not as strong as true forged wheels, they're considerably stronger than standard cast wheels.

Standard cast wheels occupy the bottom of the strength hierarchy. The manufacturing process involves pouring molten aluminum into molds, which creates that pebble-like internal structure I mentioned. While modern casting techniques have improved significantly, the fundamental limitations of the process mean cast wheels will always be heavier for a given strength or weaker for a given weight compared to forged alternatives.

For professional racing applications or high-performance street cars, forged monoblock wheels remain the gold standard for strength. This is why premium manufacturers like Ferrari, Lamborghini, and Porsche often equip their vehicles with forged wheels as standard equipment.

What Are The Benefits Of Forged Wheels?

When I consult with performance shops and enthusiasts about upgrading to our Tree Wheels forged products, many are initially focused only on aesthetics. They're often surprised when I explain that the most significant benefits are actually performance-based.

The primary benefits of forged wheels include dramatic weight reduction improving acceleration and handling, superior strength preventing damage from impacts, enhanced safety through better structural integrity, and improved fuel efficiency through reduced rotational mass. The investment pays dividends across overall vehicle performance.

Weight reduction represents perhaps the most transformative benefit. Our typical forged wheel weighs 25-40% less than a comparable cast wheel. This isn't just any weight reduction—it's specifically "unsprung weight" (weight not supported by the vehicle's suspension), which has a multiplied effect on performance. For every pound reduced in wheel weight, the effect on acceleration and handling is equivalent to removing several pounds from the vehicle's overall weight.

| Performance Aspect | Improvement with Forged Wheels | Explanation |

|---|---|---|

| Acceleration | 5-10% improvement | Less rotational mass requires less energy to accelerate |

| Braking | Up to 8% shorter distances | Less momentum to stop, better suspension contact |

| Handling Response | Noticeably sharper | Reduced unsprung weight allows suspension to work better |

| Fuel Economy | 2-5% improvement | Less energy needed to move wheels, reduced rolling resistance |

| Ride Comfort | Smoother ride | Better suspension response over bumps and road imperfections |

| Durability | 2-3x longer lifespan | Greater resilience to impacts and fatigue |

I've repeatedly seen this translate into measurable performance improvements. Clients who switch to our forged wheels report better acceleration times, shorter stopping distances, and more responsive handling. One client who tracks his BMW M3 saw his lap times improve by nearly 2 seconds after switching to our one-piece forged wheels—without any other modifications.

The superior strength of forged wheels also means they can be designed with less material while maintaining safety margins. This allows our engineers to create more aggressive, lighter designs that wouldn't be possible with cast wheels. The bamboo-like fibrous internal structure provides both strength and flexibility that's impossible to achieve with the granular structure of cast wheels.

Fuel efficiency improvements might seem minor, but they add up. The reduced rotational mass means the engine doesn't work as hard to accelerate the wheels, and the lighter unsprung weight improves suspension performance, keeping tires in better contact with the road. Several customers who monitor their fuel consumption closely have reported improvements of 2-5% after switching to our forged wheels.

While the initial investment is higher than cast wheels, the long-term value proposition becomes clear when considering all these benefits together, plus the enhanced durability that often means forged wheels outlast multiple sets of cast alternatives.

How Strong Are Forged Rims?

As someone who has tested countless wheel designs in both laboratory and real-world conditions, I can confidently address the impressive strength characteristics of properly manufactured forged wheels.

Forged wheels can withstand approximately 300% more stress than cast wheels before failure. They can flex under impact rather than crack, routinely pass testing that simulates hitting potholes at high speeds, and maintain structural integrity under extreme cornering forces exceeding 1.5G that would deform or crack cast alternatives.

The strength of our forged wheels is perhaps best illustrated through our testing protocols. Every wheel design we produce undergoes rigorous testing that far exceeds standard road conditions. Impact testing simulates hitting potholes at highway speeds repeatedly—tests where cast wheels often fail after just a few impacts. Our forged wheels typically withstand hundreds of similar impacts before showing any signs of structural compromise.

| Test Type | Cast Wheel Performance | Forged Wheel Performance |

|---|---|---|

| Impact Resistance | Typically fails after 5-10 severe impacts | Can withstand 100+ similar impacts |

| Cornering Load | Begins to deform at ~1.0G lateral force | Maintains structural integrity beyond 1.5G |

| Fatigue Testing | Shows cracks after simulated 3-5 years | No significant fatigue after simulated 10+ years |

| Weight-bearing Capacity | Requires more material for safety margin | Achieves same safety with 25-40% less material |

| Temperature Resistance | More prone to structural changes | Maintains properties across wider temperature range |

Cornering force tests are equally revealing. When a vehicle takes a high-speed turn, enormous lateral forces are placed on the wheels. Our testing replicates cornering forces exceeding 1.5G—similar to what you might experience on a racetrack. Under such conditions, cast wheels often begin to flex and, in extreme cases, can crack or fail entirely. The fibrous, bamboo-like internal structure of our forged wheels maintains dimensional stability even under these extreme conditions.

This strength translates directly to safety margins. A wheel's failure at speed can be catastrophic, potentially causing loss of vehicle control. The superior strength of forged wheels provides an additional safety buffer that becomes critical in emergency situations like hitting an unexpected road hazard at highway speeds.

One particularly telling test involves mounting wheels on specialized equipment that applies loads simulating years of use in compressed timeframes. Cast wheels typically develop fatigue cracks after simulating 3-5 years of aggressive driving. Most of our forged designs show no significant fatigue even after simulated test periods equivalent to 10+ years of similar driving conditions.

The forging process creates wheels that not only resist cracking but can actually flex slightly and return to their original shape—something cast wheels simply cannot do reliably. This resilience comes from that aligned grain structure I compare to bamboo fibers, which provides both strength and a degree of elastic flexibility that prevents catastrophic failure.

Conclusion

Forged wheels deliver significantly superior strength, performance and safety compared to cast alternatives due to their unique molecular structure and manufacturing process. While the investment is higher, the benefits to vehicle dynamics are undeniable.

At Tree Wheels, we remain committed to bringing the highest quality forged wheels to enthusiasts who understand that what's beneath your car matters just as much as what's under the hood.