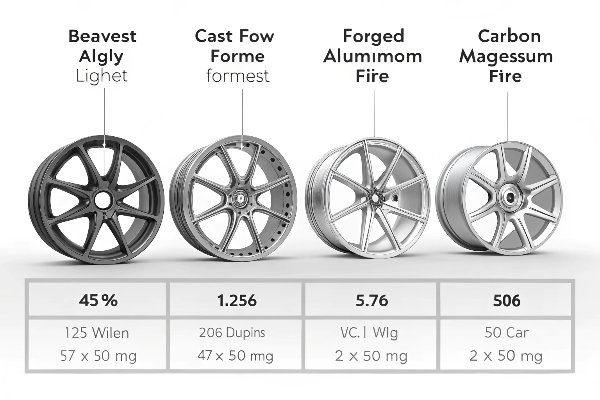

Customers often ask me this question when looking for new wheels. The confusion between forged and alloy wheels creates uncertainty about which option delivers better performance and value.

Yes, forged wheels are lighter than cast alloy wheels, typically 25-40% lighter for the same size. This weight reduction comes from the manufacturing process where aluminum is compressed under massive pressure (around 9,000 tons), creating a denser molecular structure that requires less material while maintaining strength.

wheels alt with forged wheel [manufacturing process](https://www.americanracing.com/news/wheel-manufacturing-techniques?srsltid=AfmBOooRolmSuPmaETifkV5jjfCD4ksXeq0wb1CQjBtv3M8lh-WmBSs2)](https://treewheels.com/wp-content/uploads/2025/09/1-forged-wheel-manufacturing-process-3d-render-.png)

When customers visit our manufacturing facility, they're often surprised by the physical differences between forged and cast wheels. While they may look similar on the surface, the internal structure and performance characteristics tell a different story. Let me clear up the confusion about wheel types and help you understand the real differences.

Are Forged Wheels The Lightest?

Many car enthusiasts wonder if they should invest in forged wheels for maximum weight reduction. Is there anything lighter than a quality forged wheel?

Forged wheels aren't absolutely the lightest wheel type available. Carbon fiber and magnesium wheels can be lighter; however, forged aluminum wheels offer the best balance of weight, strength, durability, and cost for most high-performance applications.

In our production testing, the weight differences between wheel types are quite revealing. Carbon fiber wheels can be up to 15% lighter than our forged aluminum wheels, but they come with significant drawbacks. They're extremely expensive (often 2-3 times the price of premium forged wheels), more vulnerable to damage from impacts, and repairs are nearly impossible.

Similarly, magnesium wheels offer impressive weight savings but are highly reactive to moisture and require special maintenance to prevent corrosion. This makes them impractical for daily driving, especially in areas with rain or snow. When I talk with customers seeking the absolute lightest option, I always discuss how these trade-offs affect real-world use.

For most premium applications, our forged aluminum wheels hit the sweet spot. A typical 19" forged wheel in our lineup weighs approximately 18-20 lbs, while its cast counterpart often weighs 24-26 lbs. This reduction in unsprung and rotational mass makes a noticeable difference in vehicle performance that our customers can actually feel when driving.

Real-World Weight Considerations

| Wheel Type | Relative Weight | Cost Factor | Durability | Maintenance |

|---|---|---|---|---|

| Cast Alloy | 100% (baseline) | 1x | Good | Standard |

| Flow-formed | 85-90% | 1.5x | Very Good | Standard |

| Forged | 60-75% | 2-3x | Excellent | Standard |

| Carbon Fiber | 50-60% | 5-8x | Variable | Specialized |

| Magnesium | 55-65% | 3-4x | Good | High |

What Type Of Wheels Are The Lightest?

With so many wheel types on the market, customers often ask which construction method produces the absolute lightest wheels available today.

Carbon fiber composite wheels are currently the lightest type of wheels available for production vehicles, typically weighing 40-50% less than traditional cast alloy wheels. However, magnesium and forged aluminum wheels are more common lightweight options due to better value and durability.

wheel](https://treewheels.com/wp-content/uploads/2025/09/3-carbon-fiber-composite-wheel-showing-lightweigh.png)

In our industry, wheel weight is a critical factor, but it's just one part of a complex equation. When we develop new wheel models at Tree Wheels, we carefully analyze how different materials and construction methods affect overall performance. Carbon fiber's impressive strength-to-weight ratio makes it the champion in pure weight reduction, but its specialized production requirements and fragility limit its practical application.

The hierarchy of wheel weight, from lightest to heaviest, typically follows this pattern: carbon fiber, magnesium, forged aluminum, flow-formed aluminum, and finally cast aluminum. However, this order doesn't necessarily translate to "best to worst" - each has specific applications where it excels.

Flow-forming (also called rotary forging) represents an interesting middle ground that's gaining popularity. This hybrid technique starts with a cast wheel but applies pressure and rotation to strengthen and thin the barrel section. The result is a wheel approximately 10-15% lighter than a fully cast wheel at a more reasonable price point than full forging.

In our testing facility, we've documented how these weight differences affect vehicle dynamics. Reducing wheel weight by just 5 pounds per corner can improve acceleration times by measurable amounts, enhance braking performance, and most noticeably, improve suspension response over bumps and during cornering. This is why professional racing teams are obsessive about wheel weight even though their budgets are substantial.

Manufacturing Effects on Weight

| Manufacturing Process | Material Efficiency | Strength | Design Flexibility | Minimum Wall Thickness |

|---|---|---|---|---|

| Casting | Low | Moderate | High | Thicker (safety margin) |

| Flow-forming | Medium | Good | Medium | Medium |

| Forging | High | Excellent | Limited by tooling | Minimized |

Are Forged Wheels Heavy?

Some customers come to us with the misconception that forged wheels might be heavier due to their superior strength. They wonder if durability comes at a weight penalty.

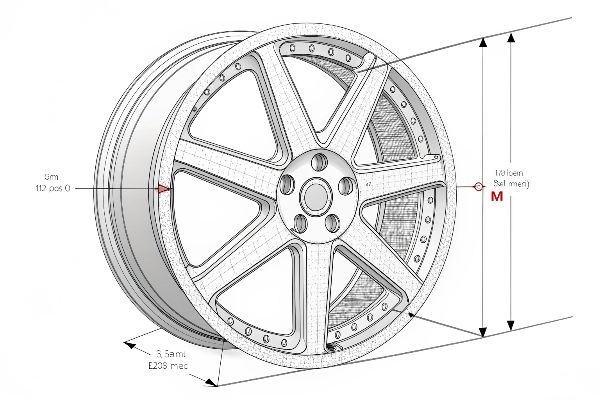

No, forged wheels are not heavy. They're actually significantly lighter than cast wheels of comparable size and design. The forging process aligns the aluminum's grain structure, increasing strength and allowing thinner wall construction while maintaining load capacity.

This misconception likely stems from associating strength with weight - in many products, stronger versions are indeed heavier. However, wheel manufacturing follows different principles. The forging process we use at Tree Wheels creates a superior metallic structure at the molecular level.

When we forge aluminum, we apply tremendous pressure that eliminates microscopic voids and aligns the metal's grain structure in the optimal direction. This results in material that can be up to 300% stronger than cast aluminum. This added strength allows our engineers to design wheels with significantly thinner walls and spokes while maintaining or exceeding safety standards.

The weight difference is substantial. For example, one of our popular 20-inch forged wheels weighs approximately 22 pounds, while a similarly styled cast wheel of the same size typically weighs around 30 pounds. This 8-pound difference per wheel adds up to 32 pounds of weight reduction for the vehicle - and it's weight removed from a particularly significant area.

Vehicle dynamics engineers particularly value wheel weight reduction because wheels represent both unsprung mass (affecting suspension performance) and rotational mass (affecting acceleration and braking). Our testing shows that one pound removed from the wheels has the equivalent impact of removing approximately 4-5 pounds from the vehicle's body. This is why performance enthusiasts are often willing to invest in forged wheels despite the higher cost.

Impact of Weight Location

| Weight Location | Impact on Performance | Relative Importance |

|---|---|---|

| Sprung weight (body) | Moderate | 1x |

| Unsprung weight (suspension) | High | 2-3x |

| Rotational weight (wheels) | Very high | 4-5x |

Are Alloy Or Forged Wheels Better?

This question comes up daily in our business. Customers want to know if the premium price of forged wheels truly delivers corresponding benefits.

Whether alloy or forged wheels are "better" depends on your priorities. Forged wheels offer superior performance, strength, and weight advantages, making them ideal for enthusiast and high-performance applications. Cast alloy wheels provide reasonable performance at a dramatically lower price point.

alt with comparison between forged and cast [alloy wheels](https://treewheels.com/are-forged-wheels-lighter-than-alloy-wheels/)](https://treewheels.com/wp-content/uploads/2025/09/5-visual-comparison-of-forged-vs-cast-alloy-wheel.png)

In my years manufacturing wheels, I've learned that "better" is always relative to the customer's needs. Both forged and cast wheels are results of technological evolution, and both serve different customer segments effectively. For most working-class families, cast wheels are completely sufficient and come with many attractive design options that look very similar to forged wheels.

The manufacturing cost difference is substantial. Our forging process requires specialized equipment, significantly more energy, and longer production times than casting. For example, creating a one-piece forged wheel requires multiple heating and pressing operations, precision machining, and more extensive quality control processes. These factors contribute to forged wheels often costing 2-3 times more than comparable cast wheels.

For performance applications, forged wheels offer clear advantages:

- Enhanced acceleration and braking due to reduced rotational mass

- Improved ride quality and handling from reduced unsprung weight

- Better fuel efficiency (typically small but measurable)

- Superior strength and crack resistance, especially important for rough roads

- Better heat dissipation during heavy braking

However, for many drivers, these benefits don't justify the cost difference. Even on my personal vehicle, I use factory-installed cast wheels, and if I were to replace them, I would likely choose flow-formed cast wheels for their better value proposition. Flow-forming represents an excellent middle ground, offering some of the weight benefits of forging at a more accessible price.

Non-professionals can hardly tell the difference between wheel types by appearance, and many cast wheels feature sophisticated designs that were previously only possible with forging. The manufacturing technology for cast wheels has improved dramatically over the past decade.

Value Proposition by Wheel Type

| Wheel Type | Performance | Durability | Design Options | Value Rating |

|---|---|---|---|---|

| Cast Alloy | Good | Good | Excellent | High |

| Flow-formed | Very Good | Very Good | Very Good | Excellent |

| Forged | Excellent | Excellent | Good | Moderate |

Conclusion

Forged wheels are significantly lighter than cast alloy wheels, offering substantial performance benefits for those who prioritize driving dynamics. However, both types have their place in the market depending on your needs and budget. At Tree Wheels, we specialize in premium forged options because we believe in delivering the absolute best performance for enthusiasts.