Have you noticed the skepticism around Chinese-made products? Despite this hesitation, nearly everything we use contains Chinese components or is entirely made in China. The question remains: do Chinese forged wheels meet international standards?

Chinese forged wheels have dramatically improved in quality since 2018 and now rank among mid to high-tier globally. Many international wheel brands quietly manufacture in China, trusting Chinese factories with their reputation-dependent products, though Japan and Germany still lead in premium manufacturing.

As someone deeply involved in wheel manufacturing, I've witnessed this evolution firsthand. The truth is that most people who work in the wheel industry know a secret: many famous international brands manufacture their wheels in China. It's an open secret that nobody talks about publicly. Think about it - would these prestigious brands risk their reputation by producing in China if the quality wasn't excellent? Absolutely not. Let me take you through the reality of Chinese forged wheels and why they deserve more recognition.

Are Forged Wheels Made In China?

Are you wondering if those premium forged wheels could possibly come from Chinese factories? Many consumers are surprised by the reality behind their favorite wheel brands.

Yes, forged wheels are extensively manufactured in China, with many international brands outsourcing production to Chinese factories. This isn't a hidden secret within the industry - it's common knowledge among professionals that numerous prestigious wheel brands rely on Chinese manufacturing while marketing themselves as international brands.

China's wheel manufacturing industry experienced a breakthrough around 2018. I remember those early days - the quality was nowhere near today's standards. However, customers rarely complained because market demand was overwhelming, allowing many Chinese forging companies to establish their financial foundation during this period.

As more manufacturers entered the market, buyers gained more options and became more selective. This competition forced factories like ours to significantly improve quality standards. If we had continued with the previous quality levels, customers would have simply gone elsewhere.

What many consumers don't realize is that when they purchase wheels from certain European or American brands, they're often buying products manufactured in Chinese factories. The only difference is they pay premium prices for the brand name. This isn't unusual in global manufacturing - it's the reality of modern supply chains. If Chinese wheels weren't up to standard, these international brands wouldn't stake their reputations on them.

Who Makes The Best Forged Wheels?

Looking to invest in the absolute best forged wheels available? The answer might surprise you, as reputation doesn't always align with actual manufacturing origins.

The best forged wheels come from specialized manufacturers in Japan (like Rays Engineering and Work Wheels) and Germany (BBS), known for pioneering technologies and exceptional quality control. However, select Chinese manufacturers have rapidly advanced, producing wheels that now compete in the mid-to-high tier globally, though we still need time to reach the absolute premium level.

I must be honest - while Chinese forged wheels have improved dramatically and can now "outperform" many manufacturing industries, the absolute top-tier wheel manufacturers remain in Japan and Germany. Their decades of experience and proprietary techniques still give them an edge in certain specialized aspects of wheel manufacturing.

At Tree Wheels, we're part of China's new generation of manufacturers working to close this gap. We're studying these advanced techniques and implementing similar processes while maintaining competitive pricing. Some Chinese factories are transitioning toward this premium segment, but it requires time for experimentation, learning, and refinement.

What truly sets the industry leaders apart is their multi-directional forging that optimally aligns metal grain structure and their detailed finishing processes. These are areas where we continue to invest and improve. Based on my years in sales, I know that customers are always available, but the real challenge is retaining them. The key question is: after ordering from us once, will customers want to return to us or try another manufacturer?

| Manufacturer Origin | Strengths | Areas for Improvement |

|---|---|---|

| Japan | Precision finishing, weight reduction | Higher costs, longer lead times |

| Germany | Engineering innovation, motorsport pedigree | Premium pricing, limited customization |

| China (Premium) | Competitive pricing, customization options | Still developing ultra-premium techniques |

| China (Standard) | Accessibility, rapidly improving quality | Building international reputation |

What Are The Disadvantages Of Forged Wheels?

Considering forged wheels but worried about potential downsides? Many buyers focus only on the advantages without understanding the limitations these premium wheels might have.

The primary disadvantages of forged wheels include significantly higher cost compared to cast alternatives, limited design flexibility due to manufacturing constraints, potential repair challenges if damaged, and longer production lead times – especially for customized designs that can take 15-35 days depending on complexity.

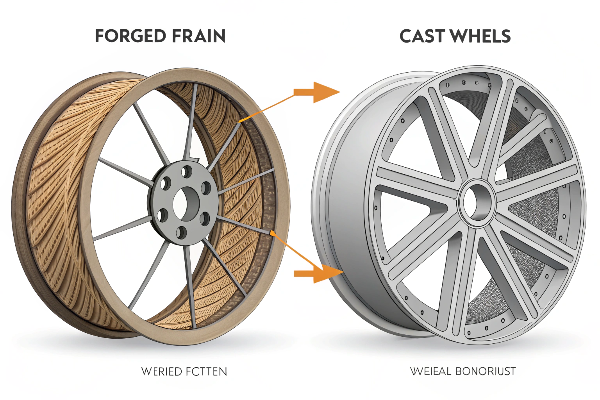

While forged wheels offer superior strength-to-weight ratio compared to cast wheels, their manufacturing process limits design possibilities. The forging process creates immense pressure on aluminum billets to align molecular structure and increase strength. However, this process restricts certain aesthetic elements that cast wheels can easily achieve.

At Tree Wheels, our production timelines reflect the craftsmanship involved: one-piece forged wheels typically require 15-20 days, two-piece designs take 20-25 days, and our complex three-piece designs need 30-35 days. These timelines exceed those of mass-produced cast wheels but ensure proper engineering integrity.

Cost remains the most significant barrier for many customers. Premium forged wheels can cost 3-5 times more than cast alternatives. This price difference reflects not just manufacturing complexity but also material quality and engineering precision. We've worked to optimize our processes to reduce costs while maintaining quality, but forging will always be more expensive than casting.

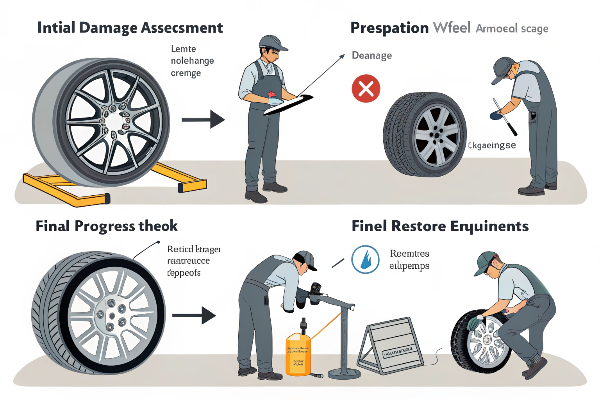

Repair challenges present another consideration. When cast wheels sustain damage, repair shops can often restore them using conventional methods. Forged wheels, with their specialized construction, require expert handling. Minor damage often requires professional assessment, as improper repairs can compromise structural integrity. This challenge intensifies with custom finishes that may be difficult to match during repair.

What To Avoid When Buying Rims?

Are you about to purchase new rims but worried about making costly mistakes? The wheel market is filled with misleading claims and counterfeit products that could compromise your vehicle's performance and safety.

When buying rims, avoid counterfeit products, misleading material claims, incompatible fitment specifications, excessive weight that hinders performance, and manufacturers without proper certification or warranty support. Always verify load ratings match your vehicle's requirements and ensure the supplier provides complete specifications.

The wheel market unfortunately includes deceptive practices that every buyer should recognize. One common issue is misrepresentation of manufacturing processes – some sellers advertise wheels as "forged" when they're actually cast with minimal forging elements or simple flow-forming. These hybrid processes have their place but don't provide the full benefits of properly forged wheels.

In my years of experience, I've learned that the most successful wheel manufacturers are those who meticulously serve each customer and carefully craft every product. Material quality varies dramatically across manufacturers. Some wheels use recycled aluminum with inconsistent properties rather than aerospace-grade materials. At Tree Wheels, we exclusively use 6061-T6 aluminum for one-piece wheels and aircraft-grade 6061-T6 or 7075-T6 aluminum for our multi-piece designs, ensuring consistent strength properties.

Documentation and certification represent another critical concern. Legitimate manufacturers provide detailed specifications including precise weight, load ratings, and test certifications. Our wheels undergo ISO testing and meet DOT requirements, with additional TÜV and JWL compliance certification in process. When suppliers can't provide these details, it often indicates corners being cut in testing or quality control.

Warranty issues plague the wheel industry. Some manufacturers offer seemingly generous warranties but make claims nearly impossible to validate. We provide a straightforward one-year warranty covering manufacturing defects with clear documentation processes. Before purchasing, investigate how warranty claims are handled, where repairs are conducted, and whether shipping costs for warranty service are covered.

| Warning Signs | What It May Indicate | How To Verify |

|---|---|---|

| Unusually low pricing | Substandard materials or processes | Request material certifications |

| Missing load ratings | Safety testing shortcuts | Demand complete specifications |

| Vague manufacturing location | Possible counterfeit product | Ask for factory information and certifications |

| Limited warranty details | Difficult claim process | Request written warranty policy |

| Unclear weight specifications | Possible performance issues | Ask for precise weight documentation |

Conclusion

Chinese forged wheels have evolved dramatically since 2018, now offering quality that competes globally while maintaining competitive pricing. The reality is that many international brands already trust Chinese manufacturing for their premium wheels.

At Tree Wheels, we believe sincerity is above all - providing genuine quality and service that keeps customers returning time after time.