Finding the perfect wheel and tire combination can be frustrating and potentially dangerous if you get it wrong. I've seen countless customers damage both their wheels and tires simply because they didn't understand proper fitment fundamentals.

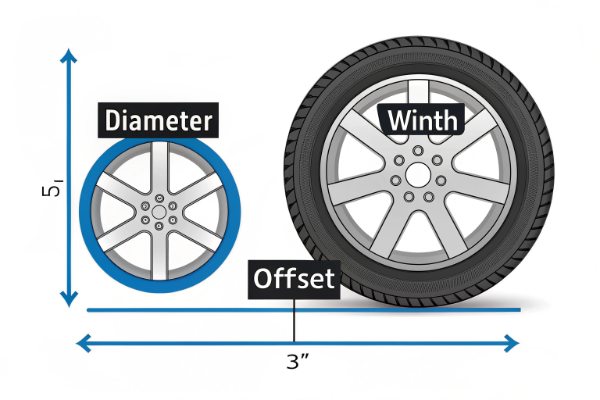

Matching wheel rims and tire sizes requires understanding three key measurements: diameter, width, and offset. The rim's width should allow the tire to maintain its intended profile, typically following the 3% rule where tire width should be approximately 3% more than the rim width for optimal performance and safety.

As the founder of Tree Wheels, I've personally overseen hundreds of custom wheel projects, and improper wheel-tire matching is the most common mistake I see. Just recently, a high-end modification shop in Dubai ordered our three-piece forged wheels but initially specified tires that would have created excessive stretch, exceeding 7% - well beyond what we recommend for safe performance. Let me guide you through the essentials of proper wheel and tire matching based on our experience manufacturing custom forged wheels.

How Do You Match Tires and Rim Sizes?

Choosing the wrong tire for your rim can lead to poor handling, uneven wear, and even catastrophic failure. I've had customers spend thousands on beautiful wheels only to ruin them with improper tire choices.

To match tires to rim sizes correctly, you need to align three key measurements: rim diameter (in inches), rim width (in inches), and tire size (using the P-metric system like 235/45R17). The tire's internal diameter must exactly match the rim diameter, while the tire width should be appropriate for the rim width according to standardized compatibility charts.

I've developed a proprietary calculation method at Tree Wheels that we apply to all custom wheel orders. This isn't just about aesthetics - it's about safety and performance. When you're selecting tires for your wheels, understanding the relationship between rim width and tire width is crucial. A tire that's too narrow for the rim will have a "stretched" appearance, while one that's too wide will bulge. Both situations compromise performance.

From our experience designing wheels for luxury vehicles worldwide, we've found the optimal tire-to-rim width ratio for performance vehicles typically falls between 1.15:1 and 1.25:1. This differs significantly from standard passenger vehicles, which is why generic sizing charts often fall short.

| Rim Width (inches) | Recommended Tire Width Range (mm) | Optimal Performance Application |

|---|---|---|

| 7.0 | 195-215 | Economy & Compact Cars |

| 8.0 | 215-245 | Mid-size Sedans |

| 9.0 | 245-275 | Performance Sedans & Sports Cars |

| 10.0 | 265-295 | High-Performance Sports Cars |

| 11.0 | 285-315 | Supercars & Track Applications |

| 12.0 | 305-335 | Exotic Cars & Racing Applications |

Remember that vehicle-specific factors also matter. Our database of over 2,000 vehicle models with precise specifications helps us recommend optimal wheel dimensions. We consider not just the basic measurements but also suspension geometry, brake clearance, and fender limitations.

What Is the 3% Rule for Tires?

Many wheel and tire failures I've witnessed stem from ignoring basic engineering principles. Tires stretched beyond their design limits can suddenly fail under load or during cornering, with potentially deadly consequences.

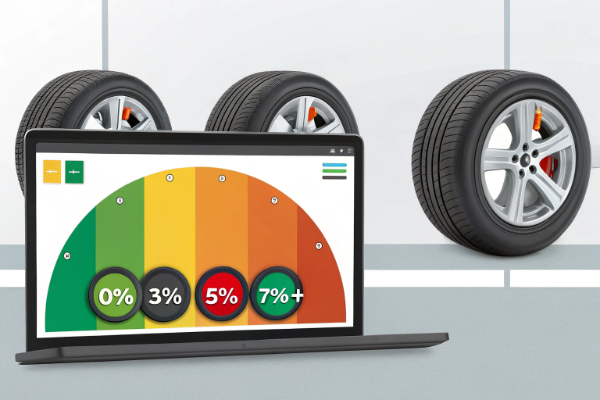

The 3% rule states that for optimal performance and safety, a tire's section width should be approximately 3% wider than the rim width on which it's mounted. This ensures the tire maintains its intended profile and load-bearing characteristics while providing proper bead seating and sidewall support.

This rule isn't just a guideline but a critical safety factor that we emphasize to all our clients. At Tree Wheels, we've built our consultation process around ensuring proper fitment. The 3% rule directly impacts load capacity - a factor too many enthusiasts overlook in favor of aesthetics.

When designing wheels for luxury SUVs in the Australian market, we found that exceeding the 3% variance resulted in up to 15% reduction in load rating. This reduction can be catastrophic for heavy vehicles or those carrying substantial loads.

| Stretch Percentage | Load Capacity Reduction | Risk Level | Recommended Use |

|---|---|---|---|

| 0% (Ideal Fit) | No reduction | Safe | All applications |

| 1-3% | Minimal (<5%) | Low Risk | Performance & Daily Use |

| 3-5% | Moderate (5-10%) | Medium Risk | Show & Limited Performance |

| 5-7% | Significant (10-15%) | High Risk | Show Only (Limited Use) |

| >7% | Severe (>15%) | Dangerous | Not Recommended |

The rule also helps maintain proper tire profile. A tire mounted on a rim that's too wide will have a flattened tread profile, leading to uneven wear and reduced grip in wet conditions. Conversely, a tire on a rim that's too narrow creates a rounded profile that reduces stability and contact patch during cornering.

While some stretching or pinching outside this 3% range might be acceptable for certain show applications, we always advise our customers about the performance and safety implications. As wheel manufacturers focused on both aesthetics and performance, we believe beautiful wheels shouldn't compromise safety.

How to Measure a Rim to Determine Tire Size?

I've encountered many customers who incorrectly measure their rims, leading to poor tire choices and fitment issues. One particular client damaged a set of our forged wheels trying to mount tires that were completely inappropriate for the rim dimensions.

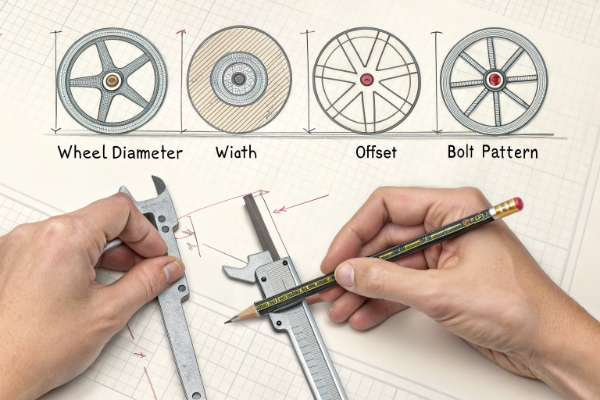

To measure a rim correctly, determine three critical measurements: the diameter (from bead seat to bead seat), width (between the inside edges of the rim flanges), and offset (distance from the mounting surface to the centerline). Use digital calipers for precision, and always measure in inches as wheel specifications typically use this unit.

Our measurement protocol for determining proper tire size includes not just these standard measurements but also a detailed assessment of the wheel well clearance. Most people focus only on diameter while neglecting the equally important width and offset measurements. This oversight leads to many fitment problems.

| Measurement | How to Measure | Common Errors | Tools Needed |

|---|---|---|---|

| Diameter | Measure from bead seat to bead seat across the center | Measuring outer edges instead of bead seats | Digital calipers or dedicated wheel gauge |

| Width | Measure between inside edges of rim flanges | Measuring outer edges of the wheel | Digital calipers |

| Offset | Distance from mounting surface to wheel centerline | Confusing with backspacing | Digital calipers & straight edge |

| Bolt Pattern | Measure center-to-center of opposite lugs (5-lug) | Using wrong measurement technique for odd-numbered patterns | Bolt pattern gauge or ruler |

| Center Bore | Diameter of center hole | None | Digital calipers |

When measuring rim width, always measure between the inside edges of the rim flanges where the tire beads sit - not the outer edges. This is the true width that determines tire compatibility. For example, a rim that measures 8.5 inches in width can typically accept tires with section widths ranging from 225mm to 255mm, depending on the application.

The offset measurement is equally critical yet often overlooked. Measured in millimeters, offset is the distance from the wheel's mounting surface to its centerline. Positive offset means the mounting surface is toward the front face of the wheel, while negative offset places it toward the back. Incorrect offset can cause tires to rub against suspension components or fenders.

We've developed specialized measurement tools at our factory that ensure precision to within 0.1mm. This level of accuracy is why our wheels consistently provide better fitment than competitors. For DIY measurements, I recommend using digital calipers rather than tape measures for improved accuracy.

Are Rim Visualizers Free to Use?

I've seen customers waste thousands of dollars on wheels that looked great in basic visualizers but didn't match their expectations in real life. This disappointment comes from relying on tools that prioritize simplicity over accuracy.

Many basic rim visualizers are free to use, offering simple drag-and-drop functionality to preview wheels on generic vehicle templates. However, these free tools typically lack accurate vehicle-specific geometry, proper lighting simulation, and precise wheel renderings, limiting their reliability for making significant purchasing decisions.

While basic visualizers are free, they often lack accuracy. That's why we've invested over $200,000 in developing our advanced 3D rendering system that accounts for vehicle-specific geometry. While basic visualizers use generic car templates, our system incorporates actual suspension geometry data to show how our wheels perform through various suspension articulation points.

| Visualizer Type | Cost | Features | Accuracy | Best For |

|---|---|---|---|---|

| Basic Online Tools | Free | Simple drag-and-drop, generic templates | Low | Initial ideas |

| Manufacturer Apps | Free/Freemium | Brand-specific wheels, some vehicle models | Medium | Brand-specific shopping |

| Professional Software | $$$$ (Business use) | Precise vehicle models, lighting effects, suspension geometry | High | Professional fitment |

| Tree Wheels System | Complimentary for clients | Custom vehicle database, actual wheel designs, real-world lighting | Very High | Custom forged wheel orders |

| AR Applications | Free to Premium | Real-time visualization on actual vehicle | Varies | Quick visual checks |

The most advanced visualization tools used by professional wheel manufacturers like us consider multiple factors: accurate vehicle dimensions, suspension geometry, proper lighting effects to show wheel finishes realistically, and precise wheel specifications. These tools cost thousands to develop and maintain, which is why truly accurate visualization is rarely available for free.

Our visualization technology provides customers with precise representations of how our forged wheels will look on specific vehicle models. We can show exactly how different finishes will appear under various lighting conditions - something free visualizers simply cannot do. We can also demonstrate clearance issues or fitment concerns before manufacturing begins.

For customers serious about wheel upgrades, I always recommend working directly with wheel specialists who have access to professional visualization tools rather than relying solely on free online visualizers. The investment in proper visualization pays dividends in customer satisfaction and avoiding costly mistakes.

Conclusion

Matching wheel rims and tires correctly involves understanding diameter, width, offset measurements, and following guidelines like the 3% rule for optimal performance and safety. Using professional measuring techniques and visualization tools ensures the best results.

At Tree Wheels, we pride ourselves on helping you find the perfect balance of form and function for your custom forged wheels – because sincerity in quality and safety always comes first.