Finding the right wheels for your JDM build can be overwhelming. With countless styles, sizes, and finishes available, many enthusiasts struggle to make the perfect choice that balances aesthetics, performance, and authenticity.

The best wheel styles for JDM car modifications are typically lightweight forged wheels in designs like mesh-style (TE37-inspired), multi-spoke patterns, or classic BBS LM styles. Sizes between 15-18 inches remain popular for authentic JDM builds, with proper fitment being crucial for both appearance and performance.

When selecting wheels for a Japanese Domestic Market build, authenticity matters as much as performance. As a manufacturer working with JDM enthusiasts worldwide, I've noticed clear patterns in what separates merely good wheel choices from the truly exceptional ones. Let's explore the specific wheel styles that have proven themselves worthy of your JDM project.

What Are the Best JDM Rims?

The hunt for perfect JDM rims can leave many enthusiasts confused and overwhelmed by options that don't quite capture that authentic Japanese tuner aesthetic.

The best JDM rims include classic designs like RAYS Volk TE37s (six-spoke mesh), Work Meister S1s (three-piece with step lips), BBS LM replicas (cross-spoke with gold centers), and Enkei RPF1s (lightweight split-spoke). These wheels balance authentic styling with performance and are available in sizes 15-18 inches with proper fitments for JDM platforms.

Our order data at Tree Wheels consistently shows BBS LM-style wheels maintaining strong popularity among JDM enthusiasts, especially those seeking a classic aesthetic. For authentic JDM styling, wheels sized between 15-18 inches tend to be preferred over the larger diameters common in other automotive subcultures.

Material choice significantly impacts both performance and visual appeal. Our one-piece forged manufacturing process is particularly well-suited for JDM vehicles since it reduces weight by 15-20% while maintaining sufficient strength for daily driving and occasional track days. This weight reduction directly improves acceleration, braking, and handling – all crucial factors for the spirited driving experience JDM enthusiasts seek.

From a finishing perspective, we've found matte bronze and high-polished nickel tones to be especially popular. These finishes are common in Japan's domestic market but relatively rare internationally, giving builds a more authentic JDM appearance. The contrast between a dark wheel finish and a brightly colored car (like Bayside Blue on a Skyline or Championship White on a Type R) creates that iconic Japanese tuner aesthetic that stands out at any meet.

| Wheel Model | Design Style | Ideal Size Range | Popular Finishes | Best For |

|---|---|---|---|---|

| RAYS Volk TE37 | Six-spoke mesh | 15-18" | Bronze, Hyper Blue | All-around performance |

| Work Meister S1 | Three-piece with step lips | 16-18" | Polished lips, color centers | Show builds with authentic style |

| BBS LM | Cross-spoke with dish | 17-18" | Gold centers, polished lips | Classic JDM aesthetic |

| Enkei RPF1 | Lightweight split-spoke | 15-17" | Matte Black, Silver | Track-focused builds |

When creating custom wheels for JDM builds, we often recommend specific offset ranges (-15 to +22) that provide the perfect "flush" stance while maintaining optimal suspension geometry and preventing rubbing issues that could compromise performance.

What Are JDM Style Wheels?

Many enthusiasts misunderstand what makes a wheel truly "JDM," focusing only on brands rather than the design philosophy that defines authentic Japanese wheel styling.

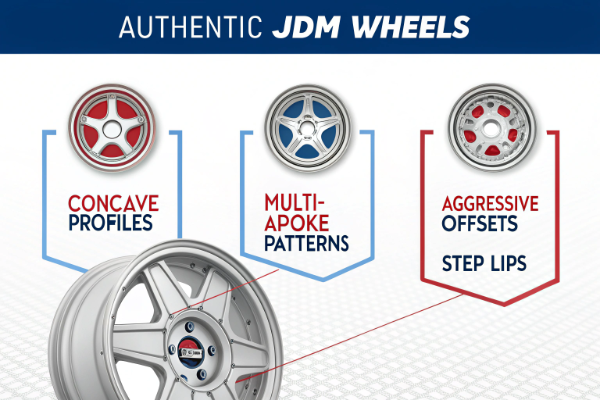

JDM style wheels embody the Japanese principle of "form follows function" with lightweight construction (usually forged), clean designs that complement rather than dominate the vehicle's lines, and proper fitment (often with aggressive offsets). Popular characteristics include concave faces, multiple spokes, and finishes like bronze, gunmetal, or hyper silver.

True JDM style wheels aren't merely about aesthetics – they represent a design philosophy that balances performance needs with visual appeal. Through my years producing wheels for the JDM market, I've observed that authentic Japanese wheel design emphasizes weight reduction without sacrificing structural integrity. This explains why forged wheels dominate the premium JDM scene.

The distinctive visual elements of JDM wheels include concave profiles that create depth, multi-spoke patterns that showcase brake components, and step lips that add dimensional interest. These design elements aren't arbitrary – they evolved from motorsport applications where weight distribution, brake cooling, and structural rigidity were paramount concerns.

| JDM Wheel Characteristic | Function | Visual Impact | Examples |

|---|---|---|---|

| Lightweight Construction | Reduces unsprung weight | Thinner, more intricate spoke designs | Forged TE37, RPF1 |

| Concave Profiles | Clears brake components, adds strength | Creates visual depth | Work Emotion CR Kiwami |

| Multi-spoke Designs | Improves cooling, distributes forces | Showcases brake components | SSR Professor SP1 |

| Aggressive Offsets | Optimizes suspension geometry | Creates "flush" fitment | Most JDM-specific wheels |

| Step Lips | Allows for width customization | Adds dimensional interest | Work Meister, SSR Formula |

From a manufacturing perspective, we've found that JDM enthusiasts are particularly knowledgeable about construction methods. Many can distinguish between cast, flow-formed, and forged wheels – and understand why these differences matter. Our two-piece and three-piece forged offerings have been especially popular for JDM builds because they allow for custom widths, offsets, and color combinations that truly personalize each project while maintaining performance benefits.

Finish selection also defines JDM wheel styling. While gloss black dominates many automotive subcultures, authentic JDM builds often feature more nuanced finishes like hyper silver, gunmetal, bronze, or machined faces with darker windows. These finishes tend to highlight the wheel's design details rather than obscuring them, reflecting the Japanese appreciation for subtle craftsmanship.

What Is the Best JDM Car to Modify?

Choosing the wrong JDM platform for modification can lead to frustration, parts availability issues, and budget overruns that derail your project before it reaches its potential.

The best JDM cars to modify include the Nissan Silvia S13/S14/S15 series, Mazda RX-7 FD, Toyota AE86, Nissan Skyline R32/R33/R34, and Toyota Supra. These vehicles offer excellent aftermarket support, responsive platforms for performance upgrades, distinctive styling potential, and communities that provide knowledge and resources for successful builds.

At Tree Wheels, we produce the highest number of custom wheels for the Nissan Silvia series (S13/S14/S15), followed closely by the Toyota AE86 and Mazda RX-7 FD. These platforms consistently demonstrate the perfect balance of modification potential, parts availability, and enthusiast following.

| JDM Platform | Ideal Wheel Sizes | Recommended Offset Range | Modification Potential | Best Application |

|---|---|---|---|---|

| Nissan Silvia S13/S14/S15 | 17×9-10.5" | +12 to +22 | Excellent | Drift/Show |

| Mazda RX-7 FD | 17×9-10" | +20 to +35 | Very Good | Performance/Show |

| Toyota AE86 | 15×7-8.5" | 0 to +25 | Good | Grassroots Motorsport |

| Nissan Skyline R32/R33/R34 | 18×9.5-10.5" | +12 to +22 | Excellent | All-around Performance |

| Toyota Supra A80 | 18×9.5-11" | +15 to +35 | Very Good | Drag/High Power Builds |

| Mitsubishi Evolution | 17×9-10" | +22 to +38 | Excellent | Rally/Grip |

| Honda S2000 | 17×9-9.5" | +40 to +45 | Good | Track/Autocross |

The Silvia series has earned its top spot for several compelling reasons. Its wheel arch design accommodates more aggressive wheel sizes and offsets, allowing builders to achieve that perfect "stance" without sacrificing driving performance. The relatively lightweight chassis responds exceptionally well to suspension modifications and power upgrades, while its drift-friendly handling characteristics make it the perfect canvas for both show builds and performance applications.

The RX-7 FD, with its distinctive rotary engine and sleek body lines, demands specific wheel fitments to complement its aggressive styling. We've found that 17×9.5 or 18×9.5 sizing with appropriate offsets (-15 to +22) provides the optimal balance of grip and controlled slide capability. These specifications come directly from our collaborations with top Japanese drift drivers whose feedback has significantly influenced our design process.

The AE86, despite its age, continues to be a popular modification platform due to its lightweight chassis, rear-wheel-drive layout, and cultural significance. Wheel choices for this platform tend to favor smaller diameters (15-16 inches) with wider widths to maintain the classic '80s JDM aesthetic while improving cornering performance.

For each of these platforms, we create custom wheel packages that account for specific suspension modifications, brake upgrades, and intended use cases. A track-focused Silvia build, for example, might utilize our lightweight one-piece forged wheels in a more conservative width to prioritize straight-line acceleration, while a show-oriented build might opt for wider three-piece configurations with aggressive offsets to maximize visual impact.

Do Black Rhino Wheels Improve Performance?

Car enthusiasts often debate whether premium wheel brands actually deliver tangible performance benefits or if they're merely selling aesthetic upgrades at premium prices.

Black Rhino wheels can improve performance if they reduce unsprung weight compared to factory wheels, offer appropriate widths for desired tire profiles, and maintain proper load ratings for the vehicle. However, true performance gains come from proper wheel construction (forged is lighter than cast), correct sizing for the application, and vehicle-specific fitment calculations.

While Black Rhino produces quality wheels, the performance question extends beyond brand names. As a forged wheel manufacturer, I can confirm that construction method significantly outweighs brand prestige when it comes to actual performance enhancement. Our testing consistently shows that reducing unsprung weight through forging processes yields measurable improvements in acceleration, braking, and handling response – benefits that transcend marketing claims.

| Wheel Construction Method | Weight Reduction | Strength | Manufacturing Process | Performance Impact |

|---|---|---|---|---|

| Cast Aluminum | Baseline | Good | Molten aluminum poured into molds | Baseline |

| Flow Formed/Rotary Forged | 10-15% lighter than cast | Very Good | Cast face with spun barrel | Moderate improvement |

| Fully Forged (One-Piece) | 15-20% lighter than cast | Excellent | Aluminum billet under pressure | Significant improvement |

| Forged Multi-Piece | Varies by design | Excellent | Separate forged components assembled | Customizable performance |

The physics behind wheel performance is straightforward: every pound reduced from wheel weight effectively feels like removing multiple pounds from the overall vehicle weight due to rotational mass principles. Our one-piece forged wheels typically weigh 15-20% less than comparable cast designs, creating a performance difference you can feel immediately, especially during direction changes and acceleration phases.

For JDM applications specifically, we've found that proper fitment calculations make a substantial difference in handling characteristics. A wheel with correct offset for the vehicle's suspension geometry will maintain optimal scrub radius and contact patch positioning through cornering, translating to more predictable handling at the limit. This is why we invest heavily in vehicle-specific fitment research rather than producing generic applications.

Width selection also plays a crucial role in performance enhancement. Our data indicates that for drift-oriented JDM builds, slightly wider wheels that allow for wider tires improve initial grip while maintaining breakaway predictability. Conversely, time attack builds often benefit from more conservative widths that prioritize lower rotational mass over absolute grip.

Material quality within the forging process creates another performance differentiation. Our wheels utilize 6061-T6 aluminum alloy that undergoes specific heat-treatment processes to optimize strength-to-weight ratio. This attention to metallurgical detail results in wheels that can withstand the rigors of aggressive driving while maintaining the weight advantages critical to performance.

Conclusion

Selecting the right wheels for your JDM build requires balancing authentic styling, proper fitment, and quality construction to achieve both the look and performance you desire. Tree Wheels offers custom forged options tailored specifically to JDM platforms, delivering the perfect combination of form and function for your Japanese classic.