Off-Road Beadlock Wheels

We manufacture and sell custom off-road beadlock wheels in over 20+ countries!

Talk To UsPlenty Blanks of Off-Road Beadlock Rims

Ready for CNC

We have all sizes 15″-24″ premium 6061-T6 aluminum alloy blanks of off-road wheel and beadlock ring in stock.

Not a Big Factory, But 20+ Years Experience

We’re a small, experienced manufacturer with 20+ years producing wheels for Chinese exporters, though only 2 years in overseas business directly. We can fulfill your order – just give us a chance. Any requirements? Let us know. We may simply need guidance on how to best showcase our capabilities.

Some Designs

Off-Road Beadlock Wheels

Below you’ll find examples of our previously manufactured off-road beadlock forged wheels.

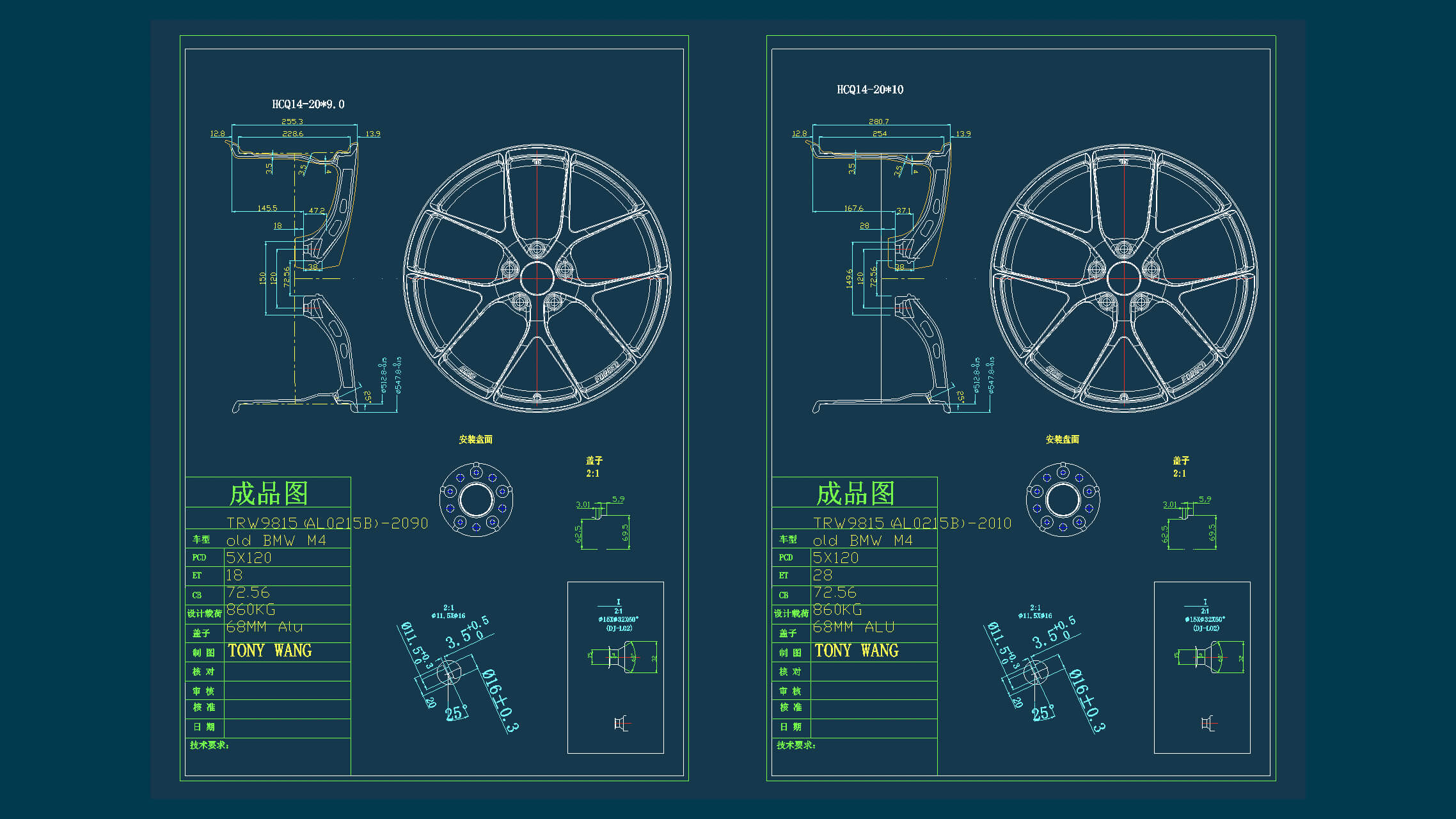

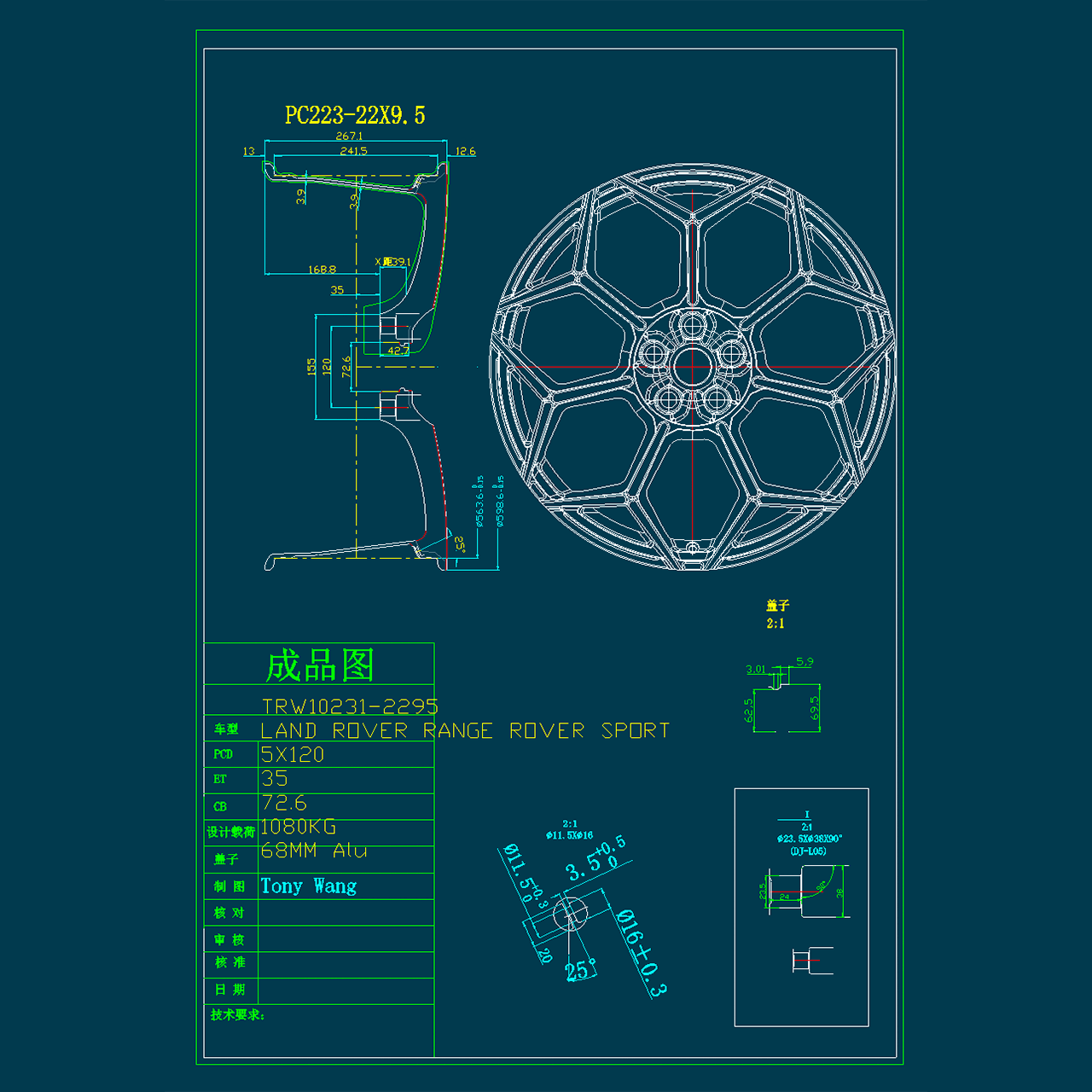

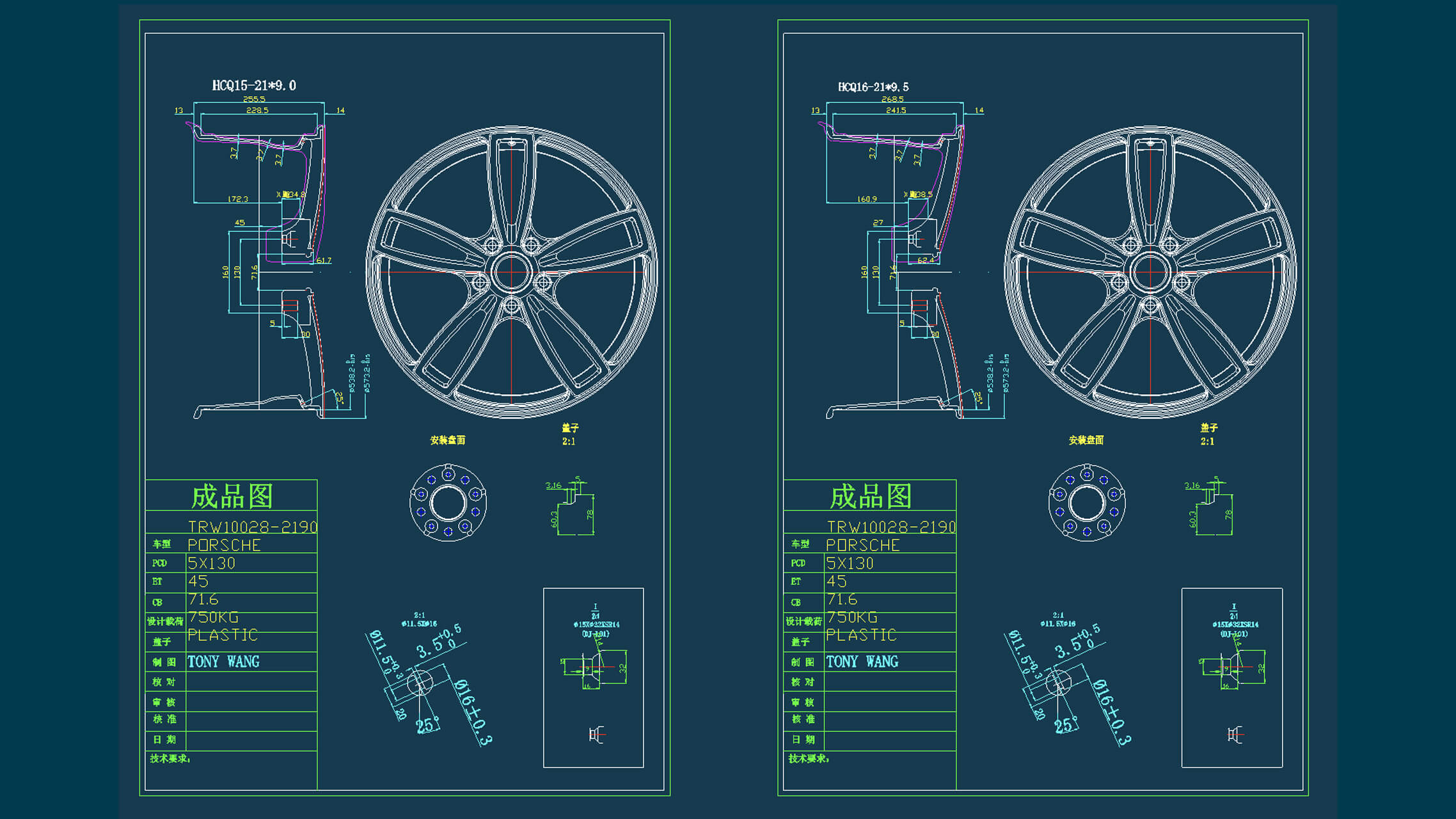

CAD(2D) Drawing & 3D Rendering Support

Before production, we provide detailed 2D CAD drawings and 3D renderings for your review. Production begins only after you confirm and approve these technical documents, ensuring your forged pieces meet all specifications.

Forged Blank Files Available

We provide detailed forged wheel blank files (14″-30″) to support your precise design process. These technical specifications allow you to:

1. Design wheel faces that perfectly fit manufacturing constraints

2. Understand exact dimensional limitations

3. Maximize creative possibilities within production parameters

Our clients value this resource for precision custom design work. Contact us to request access to these essential design files for your next 1-piece forged wheel project.

1. Design wheel faces that perfectly fit manufacturing constraints

2. Understand exact dimensional limitations

3. Maximize creative possibilities within production parameters

Our clients value this resource for precision custom design work. Contact us to request access to these essential design files for your next 1-piece forged wheel project.

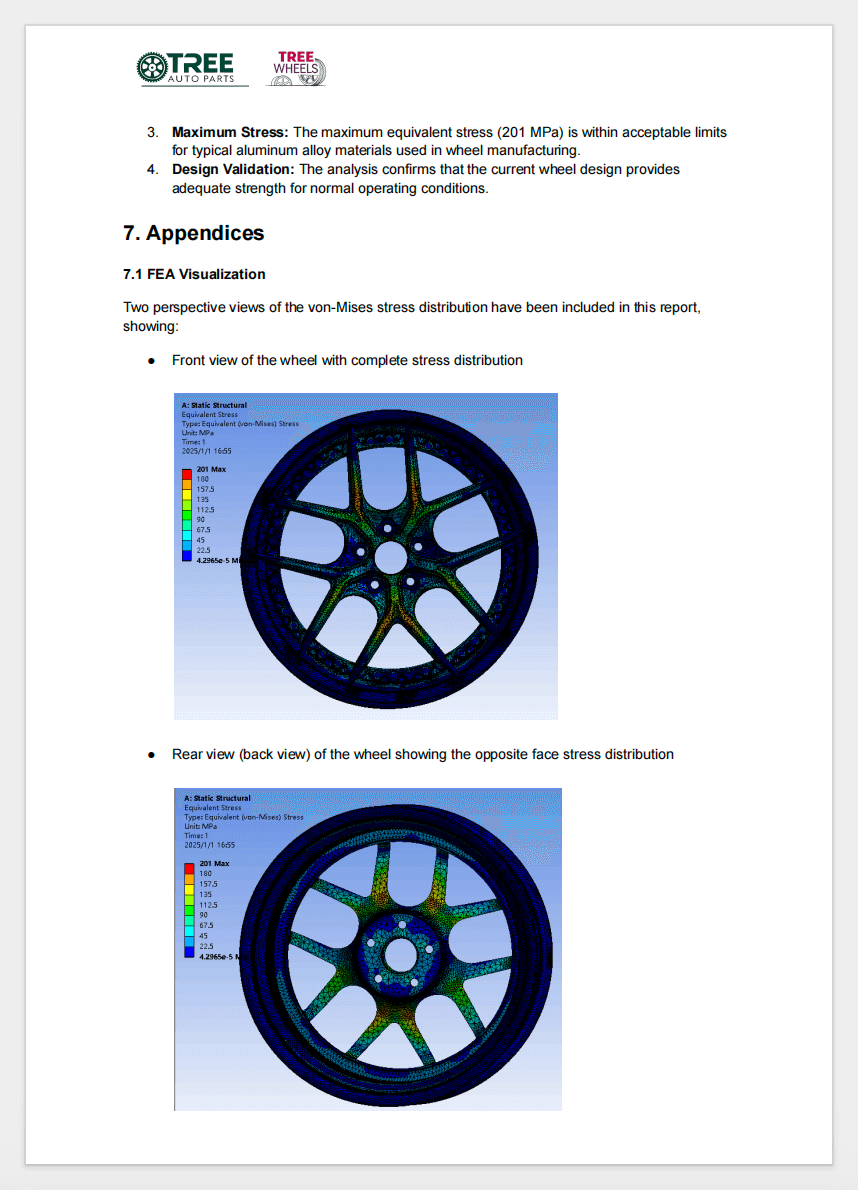

Forged Strength Analysis FEA Report

For Forged Wheels we do, no matter for personal buyers or brands, we will use static structural methodology to evaluate the stress distribution under standard loading conditions.

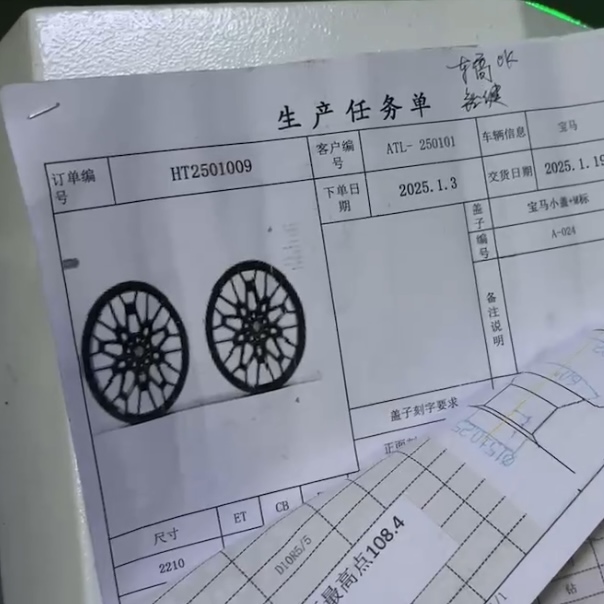

Production Progress

How We Do

STEP 1

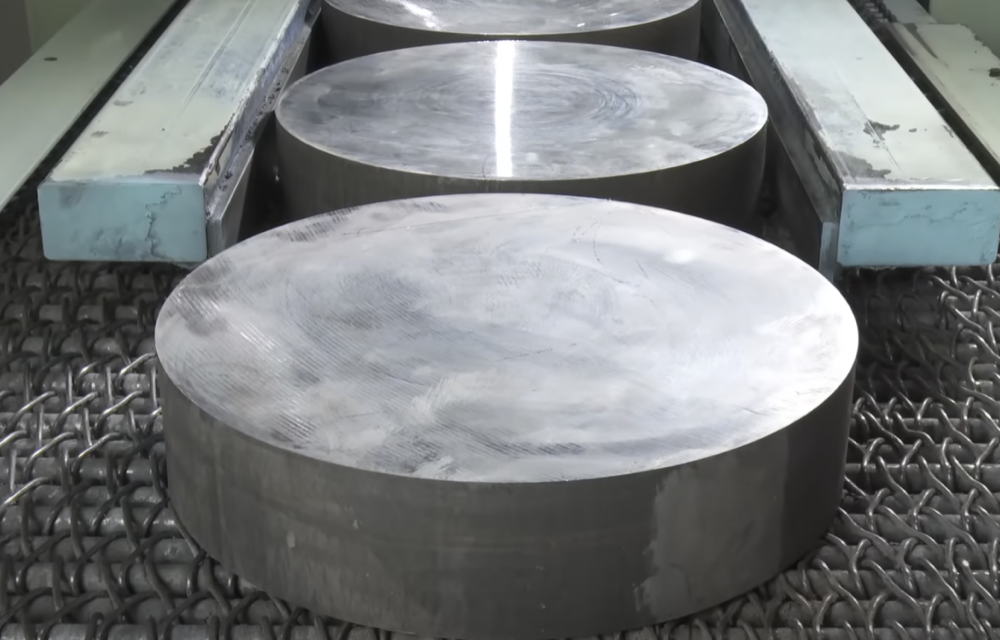

Raw Material Selection (A6061 T6)

Tree Wheels selects high-quality aluminum alloys, ensuring strength, durability, and performance through rigorous material testing and supplier evaluation.

STEP 2

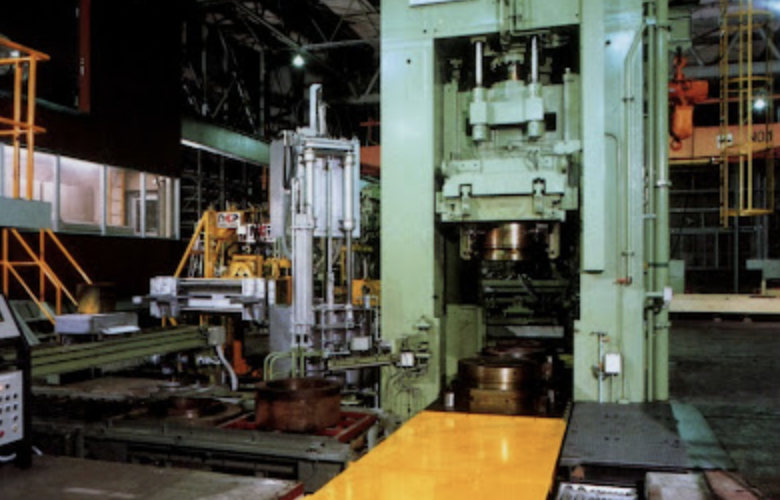

Forging (10,000 Tons)

High-pressure forging or precision casting shapes raw aluminum into wheel blanks, ensuring structural integrity, lightweight design, and enhanced performance.

STEP 3

lathe blank

The raw aluminum wheel blank is spun and shaped on a lathe to achieve the precise outer diameter and hub dimensions.

STEP 4

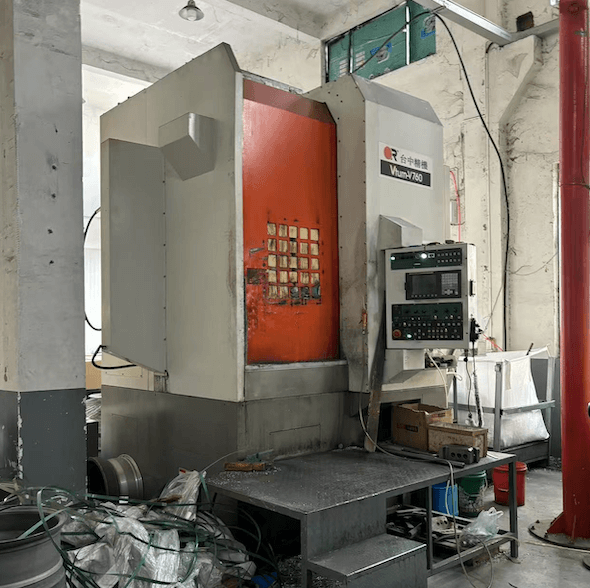

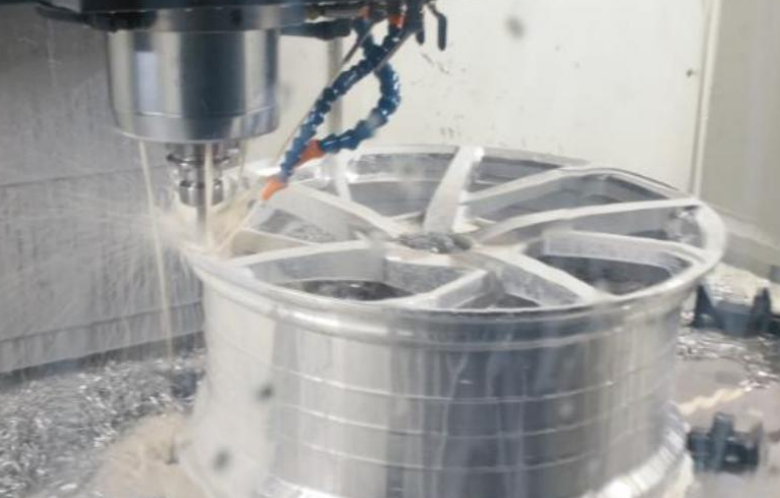

CNC Machining

Advanced CNC machines precisely cut, drill, and refine wheel designs, achieving exact specifications, smooth surfaces, and superior balance.

STEP 5

Heat Treatment (T6)

Wheels undergo controlled heating and cooling cycles to enhance strength, durability, and resistance to stress, ensuring long-lasting performance.

STEP 6

Surface Polishing

Custom coatings, polishing, painting, and anodizing processes enhance aesthetics, corrosion resistance, and provide various color and texture options.

STEP 7

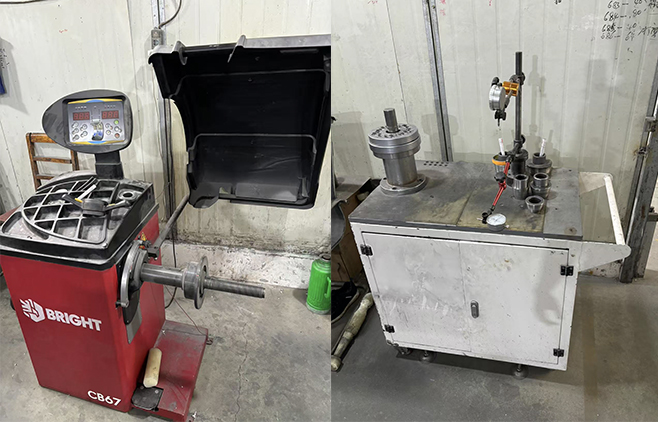

Dynamic Balancing Testing & Radial Runout Testing

Each component undergoes precision dynamic balancing to eliminate vibration, followed by radial runout testing to verify perfect circular rotation, ensuring optimal performance and longevity.

Request Free Quote

Our team will reply you within 1 working day!