Choosing the wrong rim material can lead to premature failure, poor vehicle performance, and even dangerous driving conditions. I've seen countless customers waste thousands of dollars on inappropriate wheel choices for their vehicles.

The best material for car rims is forged aluminum alloy. It offers superior strength-to-weight ratio, excellent durability, better heat dissipation, and enhanced performance characteristics compared to steel or cast aluminum alternatives. Forged wheels are created under intense pressure, resulting in a denser molecular structure.

I've been in the wheel manufacturing industry for years, and I can tell you that rim material selection impacts everything from fuel efficiency to handling and safety. The right wheel isn't just about looks—it's about performance, durability, and value. Let's dive deeper into what makes certain materials stand out.

What is the Best Material for Rims?

When customers ask me about rim materials, they're often overwhelmed by conflicting information. Many fall for marketing gimmicks promising impossible combinations of strength, weight, and affordability.

Forged aluminum alloy is the best overall material for car rims. At TreeWheels, we use premium 6061-T6 and 7075 aerospace-grade aluminum heated to 480-510°C and forged under 3000 tons of pressure, creating a molecular structure that's significantly denser than cast wheels.

The superiority of forged aluminum comes from its manufacturing process. Unlike casting, where molten aluminum is simply poured into a mold, forging applies immense pressure to aluminum billets. This eliminates the microscopic air pockets and creates a uniform grain structure throughout the wheel.

| Material Type | Manufacturing Process | Molecular Structure | Strength-to-Weight Ratio | Relative Cost |

|---|---|---|---|---|

| Forged Aluminum | High-pressure forming of solid aluminum | Dense, aligned grain structure | Excellent | High |

| Cast Aluminum | Pouring molten metal into molds | Contains microscopic air pockets | Good | Medium |

| Steel | Rolling and welding | Uniform but heavy | Moderate | Low |

| Magnesium Alloy | Various methods (rare in consumer wheels) | Very lightweight but reactive | Very High | Very High |

In our production facility, we've refined this process to perfection. The molecular alignment achieved during our forging process results in wheels that are not only stronger but also more responsive to stress. This translates directly to on-road performance. I remember testing a set of our one-piece forged wheels against premium cast alternatives on a track—the difference in cornering stability was immediately noticeable to even casual drivers.

Beyond strength, properly forged wheels offer weight advantages too. A lighter wheel reduces unsprung mass, improving acceleration, braking, and fuel efficiency. Our engineering team has developed proprietary Y-spoke designs that maintain structural rigidity while reducing weight. In comparative testing, this design showed an 18% reduction in tire deformation during aggressive cornering, directly improving handling precision.

What is the Most Durable Rim Type?

I've seen countless wheels fail prematurely—from budget cast wheels cracking at the first pothole to expensive chrome-plated wheels corroding after one winter season. These failures often come from choosing the wrong type of wheel.

Multi-piece forged wheels offer the highest durability in real-world conditions. Their sophisticated construction allows for optimal stress distribution, and their T6 heat-treated aluminum components provide the best balance of hardness and toughness. At TreeWheels, our three-piece forged wheels undergo rigorous impact and fatigue testing.

Durability in wheels comes down to two critical factors: material integrity and structural design. Our engineering team uses Finite Element Analysis to simulate stress distribution under various driving conditions, identifying and reinforcing high-stress areas.

| Wheel Type | Impact Resistance | Fatigue Resistance | Weight | Best Application |

|---|---|---|---|---|

| One-Piece Forged | Excellent (+45% vs cast) | Excellent | Lightest | Performance vehicles, track use |

| Multi-Piece Forged | Very Good (+30% vs cast) | Excellent | Light | Luxury vehicles, custom fitment |

| Flow-Formed | Good | Good | Moderate | Daily drivers, sport applications |

| Gravity Cast | Moderate | Moderate | Heavier | Entry-level aftermarket |

| Steel | Good (tends to bend not break) | Moderate | Heaviest | Utility vehicles, winter use |

The heat treatment process is another crucial aspect that's often overlooked. Many manufacturers cut corners by using T4 heat treatment instead of the more durable T6 process. While this difference isn't immediately obvious, it becomes apparent under extreme conditions when lower-quality wheels deform or crack. Every TreeWheel product undergoes T6 heat treatment to ensure optimal hardness and toughness balance.

I recall a customer who switched from premium cast wheels to our forged options for his track car. After two seasons of aggressive driving that had previously required multiple wheel replacements, our forged wheels showed minimal signs of stress. This real-world durability translates to better value despite the higher initial investment.

What to Avoid When Buying Rims?

The market is flooded with attractive but potentially dangerous wheel options. I've seen the aftermath of wheel failures, and they're often traced back to simple oversights during the purchase decision.

Avoid wheels lacking proper certifications like TÜV, JWL, or DOT standards, as these ensure basic safety requirements are met. Be wary of extraordinarily cheap forged wheels, wheels with improper fitment specifications, and those with inadequate weight ratings for your vehicle.

](https://treewheels.com/wp-content/uploads/2025/09/image-4-a-close-up-photograph-of-quality-certifica.png)

One critical mistake I see repeatedly is choosing wheels based solely on appearance without considering their construction. Many "lightweight" wheels achieve their reduced weight by removing structural material, compromising integrity.

| What to Avoid | Why It's Problematic | How to Check | TreeWheels Standard |

|---|---|---|---|

| Uncertified Wheels | May not meet basic safety standards | Look for TÜV, JWL, DOT markings | All wheels certified to international standards |

| Improper Fitment | Causes handling issues, excessive wear | Verify load rating and exact specifications | Custom engineering for precise fitment |

| Poor Finishing Processes | Leads to premature corrosion | Research manufacturer's process | Multi-stage treatment with environmental testing |

| "Too Good To Be True" Pricing | Usually indicates corners cut in manufacturing | Compare with market averages for similar products | Competitive pricing for true forged quality |

| Excessive Design With Little Substance | Weakens structural integrity | Look for engineering-based designs | FEA-optimized spoke patterns |

Another common pitfall is improper coating and finishing processes. Many aftermarket wheels use decorative finishes that actually accelerate corrosion when damaged. Our production process incorporates multi-stage surface preparation and advanced coating technologies that provide both aesthetic appeal and environmental protection.

I once consulted for a modification shop dealing with recurring customer complaints about vibration issues. The problem was traced to inconsistent manufacturing tolerances in their previous wheel supplier's products. Precision matters—even slight variations in hub centricity can cause noticeable vibration at highway speeds. Our manufacturing process maintains tolerances within 0.02mm across all critical dimensions.

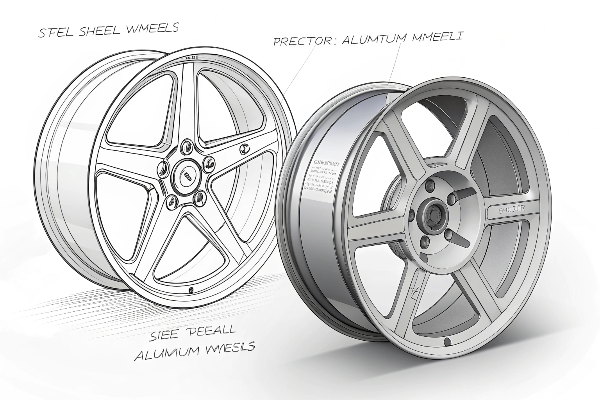

Which Rims are Better, Steel or Aluminum?

I often meet customers torn between the affordability of steel and the performance benefits of aluminum wheels. This choice depends significantly on your driving priorities and vehicle application.

Aluminum wheels are generally better than steel for performance applications due to their lighter weight, better heat dissipation properties, and superior aesthetic options. However, steel wheels offer better impact resistance in extreme conditions and are more cost-effective for utility vehicles.

Beyond the basic weight differential, aluminum wheels—particularly forged ones—offer vibration absorption characteristics that significantly improve ride quality.

| Characteristic | Steel Wheels | Cast Aluminum | Forged Aluminum |

|---|---|---|---|

| Weight | Heavy (25-35 lbs) | Medium (20-25 lbs) | Light (15-22 lbs) |

| Impact Behavior | Bends, rarely breaks | Can crack if hit hard | Highly resistant, maintains structure |

| Heat Dissipation | Poor | Good | Excellent |

| Vibration Absorption | Poor | Good | Excellent |

| Aesthetic Options | Limited | Good | Excellent |

| Manufacturing Precision | ±0.1mm | ±0.05mm | ±0.02mm |

| Cold Weather Performance | Good | Moderate | Good |

| Relative Cost | $ | $$ | $$$-$$$$ |

| Ideal Application | Winter wheels, Off-road | Daily drivers | Performance, Luxury |

In our lab testing, we've observed that properly designed aluminum wheels can reduce unsprung weight by up to 40% compared to equivalently sized steel wheels. This weight reduction has cascading benefits throughout the vehicle's dynamics, from improved acceleration to reduced braking distances and enhanced fuel efficiency.

Steel wheels do remain relevant for certain applications. Their malleability means they tend to bend rather than break under extreme impacts, which can be advantageous in some off-road scenarios. They're also significantly less expensive to replace, making them practical for utility vehicles operating in harsh conditions.

The finishing possibilities present another significant difference. While steel wheels are typically limited to paint or simple covers, aluminum wheels—especially our forged offerings—can be finished with precision machining, complex multi-tone color schemes, and specialized surface treatments that both enhance appearance and provide environmental protection.

Conclusion

Forged aluminum alloy wheels offer the best combination of strength, weight, and performance for most vehicles. Their superior molecular structure delivers durability that far outweighs their higher initial cost.

At TreeWheels, we're committed to delivering the perfect balance of engineering excellence and customization options in every forged wheel we manufacture.