Gaming racing wheels cost a fortune today. Many players face sticker shock when shopping for quality wheels, finding prices that rival actual car parts. This pricing barrier keeps many enthusiasts from experiencing realistic racing simulation.

Gaming racing wheels are expensive due to their complex force feedback systems, precision engineering, and high-quality materials. Entry-level wheels start around $200-300, while professional-grade equipment can exceed $2,000, reflecting the specialized technology and limited production runs that drive up manufacturing costs.

As someone who manufactures high-performance forged wheels for actual race cars, I see fascinating parallels between simulation equipment and real-world automotive components. Both industries serve passionate enthusiasts willing to pay premium prices for authentic experiences. Let's explore why these gaming peripherals command such high prices and what factors influence their cost.

Why Are Game Racing Wheels So Expensive?

The price of gaming wheels makes many casual gamers hesitate. When basic controllers cost under $50, seeing wheels priced at hundreds or even thousands of dollars creates serious sticker shock for newcomers.

Gaming racing wheels are expensive primarily because they incorporate sophisticated force feedback motors, precision sensors, and durable materials. These components accurately simulate the physical sensations of driving, requiring complex engineering and manufacturing processes that significantly increase production costs compared to standard controllers.

The reality is that racing, both virtual and real, has always been an expensive passion. In my years creating high-end forged wheels, I've witnessed how racing culture accepts premium pricing as part of the experience. Just as real-world motorsport enthusiasts don't blink at spending tens of thousands on vehicle modifications, serious sim racers understand quality equipment demands investment.

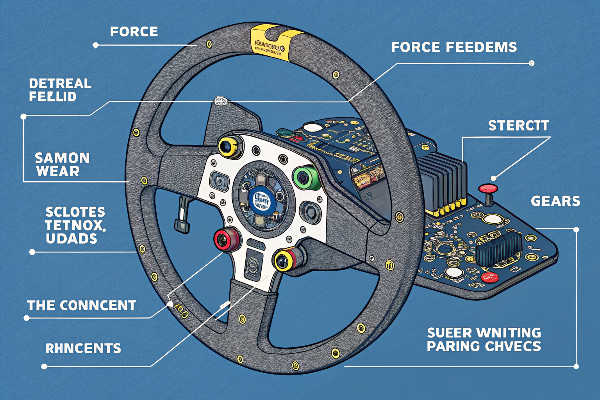

When we examine the technology inside premium racing wheels, the costs make more sense. Force feedback systems use powerful motors and gears that physically push back against your hands, replicating how a real steering wheel would feel on different surfaces or during collisions. This complex mechanical and electronic integration requires precision engineering that standard game controllers simply don't need.

Manufacturing volumes also play a crucial role in pricing. While standard controllers sell millions of units, racing wheels target a specialized audience of perhaps thousands. These limited production runs prevent manufacturers from achieving the economies of scale that drive down costs for mass-market products. This mirrors what we see in the forged wheel industry, where specialized manufacturing processes and smaller production batches naturally result in higher per-unit costs compared to mass-produced cast wheels.

The most devoted racing enthusiasts often understand this value proposition inherently. Racing is fundamentally an expensive hobby – even keeping a real race car maintained can cost hundreds of thousands annually without driving it once. In this context, spending a few thousand dollars on simulation equipment represents a relatively modest investment for those passionate about the sport.

What Is The Most Expensive Gaming Wheel?

Looking at ultra-premium racing wheels can cause serious wallet panic. Some setups cost more than entry-level real cars, leaving many wondering if any virtual experience could possibly justify such prices.

The most expensive gaming racing wheels include the SimXperience AccuForce Pro V2 ($1,699), Fanatec Podium F1 ($1,799), and custom Simucube 2 Ultimate setups exceeding $3,000 with specialized steering wheels. These premium systems feature industrial-grade components, direct-drive motors providing unfiltered force feedback, and precision engineering approaching professional training simulators.

The peak of simulation racing equipment truly showcases extraordinary engineering. As someone immersed in high-performance automotive manufacturing, I appreciate the technical achievements these products represent. The most expensive wheels typically use direct-drive technology, where the steering wheel connects directly to the motor shaft without gears or belts. This creates the most realistic and responsive feel possible, similar to how our one-piece forged wheels provide direct road feedback compared to multi-piece alternatives.

Premium Racing Wheel Technology Comparison

| Feature | Entry-Level ($200-500) | Mid-Range ($500-1,200) | Professional ($1,200+) |

|---|---|---|---|

| Force Feedback | Gear or belt-driven | Belt-driven or hybrid | Direct-drive |

| Torque | 2-3 Nm | 6-12 Nm | 15-30+ Nm |

| Construction | Plastic and rubber | Metal and leather | Aircraft-grade aluminum and premium leather |

| Rotation Angle | 270-900° | 900-1080° | 1080-1440° |

| Immersive Realism | Basic | Good | Exceptional |

The SimXperience AccuForce Pro V2 and Fanatec Podium systems feature industrial-grade motors borrowed from robotics and manufacturing automation. The Simucube 2 Ultimate takes this further with components that would be at home in professional flight simulators or military training equipment. These systems often draw more power than many household appliances and require dedicated electrical setups.

For true racing enthusiasts, these costs must be viewed in context. Real motorsport has always been associated with significant financial investment. Keeping a competition-level race car maintained costs hundreds of thousands annually even without racing it. When viewed through this lens, spending a few thousand dollars on a high-fidelity simulation setup represents tremendous value—providing the racing experience without the astronomical costs of actual track time.

The difference between mid-range and ultra-premium wheels isn't just marketing—it's tangible in the materials, engineering precision, and sensory experience they deliver. Much like our approach to creating top-tier forged wheels, these manufacturers use aerospace-grade materials, precision machining, and extensive quality control to deliver products that satisfy the most demanding drivers.

Why Is Fanatec So Expensive Now?

Fanatec's prices have climbed significantly in recent years. Many loyal customers feel frustrated seeing their favorite brand move increasingly into premium territory, wondering if the company has abandoned its core market.

Fanatec's recent price increases stem from multiple factors: global supply chain disruptions affecting electronics components, increased material costs, currency fluctuations, and a strategic shift toward higher-end market segments. The company has invested heavily in research and development for direct-drive technology while facing increased manufacturing expenses, passing these costs to consumers.

In our forged wheel manufacturing business, we've faced many of the same economic pressures affecting Fanatec's pricing strategy. The global supply chain disruptions since 2020 have dramatically increased costs for electronics components and raw materials. Aluminum prices—critical for both high-quality wheels and racing peripherals—have witnessed significant volatility, directly impacting manufacturing expenses.

Fanatec's strategic decision to develop more sophisticated direct-drive systems has required substantial R&D investment. This mirrors what we see across the high-performance automotive sector, where advanced technology demands significant development costs that must be recouped through product pricing. Their ClubSport and Podium lines represent a move upmarket, targeting serious sim racers willing to invest more for superior performance.

Key Factors Driving Fanatec's Price Increases

| Factor | Impact on Pricing | Industry Parallel |

|---|---|---|

| Supply Chain Disruption | Component costs up 30-80% | Similar increases in automotive electronics |

| R&D Investment | Developing direct-drive technology | Comparable to advanced wheel manufacturing technologies |

| Currency Fluctuations | Euro-USD exchange impacts | Global pricing challenges for export-focused manufacturers |

| Market Positioning | Strategic shift to premium segments | Similar to our focus on high-end forged wheels |

| Limited Production | Smaller production runs of specialty items | Mirrors custom wheel manufacturing economics |

The economics of specialized manufacturing create natural price pressures. Fanatec's production volumes, while significant in the simulation world, remain tiny compared to mainstream gaming peripherals. This creates the same economies of scale challenges we face producing custom forged wheels. When manufacturing thousands rather than millions of units, fixed costs distribute across fewer products, inherently raising per-unit pricing.

For racing enthusiasts accustomed to the real motorsport world's economics, these prices remain relatively reasonable. The racing culture has always accepted premium pricing—after all, even basic track day events can cost thousands, and professional racing involves astronomical figures. When a race car's annual maintenance can reach hundreds of thousands without even driving it, spending a few thousand on simulation equipment represents significant value for the racing experience it delivers.

Why Are Forged Wheels So Expensive?

Many car enthusiasts experience shock when comparing forged wheel prices to standard cast wheels. The price difference can be 3-5 times higher, leading many to question whether the performance benefits justify the premium.

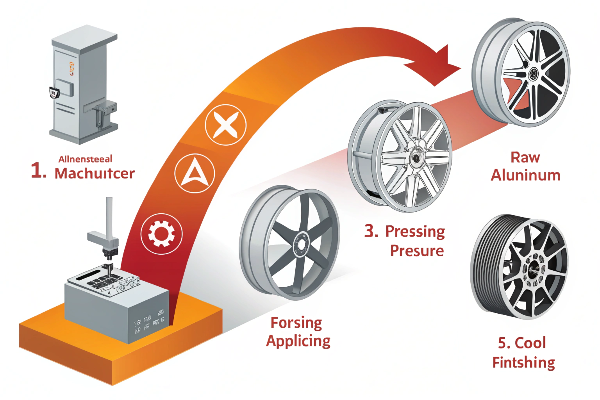

Forged wheels are expensive because they're manufactured through an intensive process where a single metal block is compressed under massive pressure (up to 10,000 tons) to create a stronger, lighter wheel without imperfections. This specialized manufacturing requires costly equipment, highly skilled labor, extensive quality control, and typically involves smaller production volumes than cast wheels.

At Tree Wheels, we understand the complexity behind creating truly exceptional forged wheels better than most. The manufacturing process fundamentally differs from mass-produced cast wheels. While cast wheels pour molten metal into molds, forging subjects solid metal to extreme pressure—creating a grain structure that provides superior strength with less material. This allows forged wheels to be both lighter and stronger, delivering tangible performance advantages.

The forging process requires specialized equipment that few manufacturers possess. Industrial forging presses exert forces exceeding 10,000 tons—machinery that costs millions to acquire and maintain. These massive capital investments must be distributed across relatively small production runs, naturally increasing per-unit costs. Our one-piece forged wheels undergo this intensive process, demanding precision at every step.

Forged vs. Cast Wheel Comparison

| Characteristic | Cast Wheels | Forged Wheels | Performance Impact |

|---|---|---|---|

| Manufacturing Process | Molten metal poured into molds | Solid metal compressed under extreme pressure | Forged wheels have superior structural integrity |

| Weight | Heavier | 25-40% lighter | Reduced unsprung weight improves acceleration, braking and handling |

| Strength | Good | Excellent | Better resistance to impact damage and deformation |

| Metal Structure | Potential for air pockets and impurities | Dense, aligned grain structure | Forged wheels maintain structural integrity under stress |

| Production Volume | High volume possible | Limited by specialized equipment | Cast wheels benefit from economies of scale |

| Customization | Limited designs | Greater design flexibility | Forged allows more precise specifications for performance |

Labor represents another significant cost factor. Creating forged wheels requires skilled machinists and technicians with specialized training. From the initial forging to CNC machining and final finishing, each wheel passes through numerous skilled hands. The extensive quality control process—including x-ray testing and stress analysis—adds further labor costs but ensures each wheel meets the highest performance standards.

The economics of specialized wheel manufacturing mirrors what we see in high-end racing simulation equipment. Both serve passionate communities willing to pay premiums for authentic performance. Just as serious sim racers understand why direct-drive wheels cost thousands, automotive enthusiasts recognize the value proposition of forged wheels. In the context of motorsport culture where annual maintenance costs can reach hundreds of thousands without even driving the car, premium wheels represent a relatively modest investment in the overall racing experience.

Conclusion

Gaming racing wheels and forged wheels share remarkable pricing similarities—both command premium prices because they deliver authentic performance through precision engineering and specialized manufacturing. At Tree Wheels, we're proud to craft premium forged wheels that deliver the same kind of authentic performance for real-world racing that quality simulation equipment provides virtually.