I've seen countless buyers struggle when sourcing truck wheels from China. The communication breaks down before it even starts! Why? A simple but critical cultural misunderstanding about what "truck wheels" actually means in different markets.

When searching for truck wheels in China, you need to specifically ask for "pickup truck wheels." In China, "truck" typically refers to large commercial vehicles, not the personal pickup trucks common in Western markets. This simple terminology difference causes many sourcing failures.

truck wheels manufacturing in China](https://treewheels.com/wp-content/uploads/2025/07/image-1-watercolor-style-create-a-watercolor-il.png)

This miscommunication can waste weeks of your time and result in completely wrong product recommendations. Let me guide you through the essential knowledge you need to successfully source high-quality truck wheels from Chinese manufacturers without the headaches I've experienced.

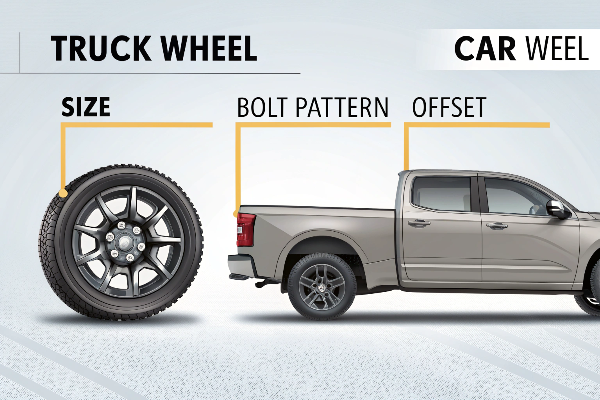

What Is the Difference Between Truck Wheels and Car Wheels?

Every time I speak with new clients, they're surprised to learn that pickup truck wheels have specific requirements that passenger car wheels don't. The confusion costs them time and money when sourcing.

Truck wheels differ from car wheels primarily in load capacity, size, and bolt patterns. Pickup truck wheels typically have higher load ratings (often H-rated), larger diameters (17-24 inches), wider widths, and different bolt patterns (5, 6, or 8 lugs) compared to standard passenger vehicles.

Diving deeper into truck wheels versus car wheels reveals several important distinctions that impact performance and safety. The table below highlights the key differences:

| Feature | Pickup Truck Wheels | Passenger Car Wheels |

|---|---|---|

| Material Thickness | Thicker, reinforced construction | Standard thickness |

| Forgings | Often H-type forgings | Standard forgings |

| Offset Range | Can achieve extreme negative offsets (up to ET-100) | Limited offset range |

| Lug Pattern | Commonly 6 or 8 lugs | Typically 4 or 5 lugs |

| Load Rating | Higher (H-rated) | Lower |

| Center Bore | Larger diameter | Smaller diameter |

| Barrel Depth | Deeper for brake clearance | Standard depth |

| Price Point | ~$100 more per wheel | Lower baseline cost |

For manufacturers like us, producing truck wheels requires different equipment settings and quality control parameters. The cost difference is notable too - typically truck wheels run about $100 more per wheel than comparable car wheels due to the additional material and specialized forgings required. When sourcing from China, understanding these technical differences ensures you're getting properly engineered products rather than oversized car wheels that might fail under truck applications.

Why Are Trucks Called Pick-up Trucks?

I remember my first meeting with Chinese manufacturers – they were completely confused when I mentioned "truck wheels." The term creates major sourcing problems without proper explanation.

Trucks are called "pick-up trucks" because they were originally designed in the 1920s to "pick up" cargo in their rear beds. The term distinguishes these personal/light commercial vehicles from larger commercial trucks, which is particularly important when communicating with Chinese manufacturers.

The historical evolution of pickup trucks reveals why this terminology distinction matters so much when sourcing wheels from China. In North America, Australia, and many Western markets, "truck" commonly refers to what Chinese manufacturers categorize as "pickup trucks." This cultural difference in vehicle classification creates significant confusion in the supply chain.

The pickup truck emerged in America as farmers and merchants needed vehicles to transport goods and materials over increasingly improved roads. Henry Ford's Model T Runabout with Pickup Body in 1925 popularized the concept, and the term "pickup" referenced the vehicle's function. Over decades, these vehicles evolved from purely utilitarian workhorses to today's diverse market of both work-focused and luxury-oriented models.

When sourcing wheels from China, this history matters because the manufacturing infrastructure categorizes vehicles differently. Chinese vehicle classifications align more with European systems, where "truck" exclusively means large commercial vehicles. This fundamental difference in terminology means that when Western buyers ask for "truck wheels," Chinese manufacturers often assume they want wheels for 18-wheelers or heavy commercial vehicles, not for Ford F-150s or Chevrolet Silverados. When communicating with Chinese suppliers, I've found that specifically using terms like "pickup truck wheels" or providing detailed vehicle models and specifications dramatically improves sourcing success rates and prevents weeks of back-and-forth confusion.

Can You Put Truck Rims on a Car?

I've had customers ask this question repeatedly, often hoping to achieve an aggressive look for their sedans or coupes. The answer isn't as simple as yes or no.

You generally cannot put truck rims on passenger cars due to incompatible bolt patterns, offsets, center bore diameters, and load ratings. While some crossover exists with certain SUVs and crossovers, using truck wheels on standard cars typically requires extensive modifications and may compromise safety.

When considering wheel compatibility across vehicle types, there are several critical technical factors that make truck-to-car wheel swaps problematic and often unsafe:

| Compatibility Factor | Pickup Trucks | Passenger Cars | Why It Matters |

|---|---|---|---|

| Bolt Pattern | 6x135mm, 6x139.7mm, 8x165.1mm | 4x100mm, 5x100mm, 5x114.3mm | Physical mounting points don't align |

| Center Bore | Larger diameter | Smaller diameter | Won't fit correctly over wheel hubs |

| Wheel Offset | Often zero or negative (ET-100 to ET0) | Usually positive (ET+35 to ET+45) | Affects wheel position, steering geometry |

| Load Rating | Higher capacity | Lower capacity | Safety concern for structural integrity |

| Wheel Weight | Heavier construction | Lighter construction | Affects suspension, handling, braking |

The most concerning issue is load capacity. Truck wheels are designed to handle significantly higher weights, which means they're often heavier themselves. This additional unsprung weight affects a passenger car's suspension dynamics, braking efficiency, and overall handling characteristics. The heavier wheels can accelerate wear on bearings, suspension components, and steering systems not designed for such loads.

From a manufacturing perspective, when we produce wheels for different vehicle types, we're engineering them for specific applications with precise requirements. Mixing these specifications doesn't just create fitment challenges - it fundamentally changes how forces are distributed throughout the wheel and the vehicle's suspension system, potentially leading to premature component failure or unsafe driving conditions.

What Is the Difference Between Trailer Rims and Truck Rims?

During a factory tour last year, a client confused trailer wheels with pickup truck wheels. It's a common mistake, but one that would have resulted in completely wrong products if not caught early.

Trailer rims differ from truck rims primarily in their load rating systems, design priorities, and intended use. Trailer wheels prioritize load capacity and durability under continuous straight-line loads, while truck wheels balance load capacity with handling, braking performance, and driver comfort for varied driving conditions.

The engineering distinctions between trailer wheels and truck wheels reflect their fundamentally different operating conditions and requirements:

| Characteristic | Trailer Wheels | Pickup Truck Wheels |

|---|---|---|

| Primary Purpose | Straight-line towing | Dynamic driving conditions |

| Manufacturing Method | Typically stamped steel or basic casting | Advanced forging (often H-type) |

| Design Focus | Pure functionality | Balance of performance and aesthetics |

| Load Rating System | ST (Special Trailer) | LT (Light Truck) |

| Steering Forces | Not designed for steering | Engineered for turning, cornering |

| Heat Dissipation | Minimal requirements | Enhanced for brake heat cycling |

| Testing Standards | Load bearing focus | Impact, fatigue, rotational tests |

| Design Complexity | Simple, utilitarian | Complex with style considerations |

The metallurgical requirements differ as well - since trailer wheels don't experience the same heat cycling from repeated braking that truck wheels do, they don't require the same heat dissipation properties or thermal stability. The bolt patterns also differ significantly between these wheel types. Trailer wheels commonly use 5 or 6 lug patterns with specific bolt circle diameters unique to trailer applications.

From a production standpoint, as a wheel manufacturer, we apply different quality control standards and testing protocols to these different wheel types. Truck wheels undergo more rigorous impact, fatigue, and rotational testing to ensure they can handle the diverse stresses of everyday driving, while trailer wheels face stricter load-bearing tests but less emphasis on impact resistance or complex force management.

Conclusion

Finding the right truck wheel manufacturer in China comes down to clear communication about exactly what you need - pickup truck wheels, not commercial truck wheels. Using the right terminology prevents costly mistakes and ensures quality.

At Tree Wheels, we specialize in customized forged wheels for all vehicles, including pickup trucks, with superior quality and personalized service.