You want the performance of one-piece wheels but love the customizable looks of three-piece designs. This dilemma leaves you stuck between two options, unsure which will give you the best of both worlds.

Yes, three-piece forged wheels can achieve a seamless one-piece look through hidden bolt designs. Manufacturers install bolts from behind, creating a clean front face without visible hardware while maintaining the customization benefits of multi-piece construction.

forged wheels comparison](https://treewheels.com/wp-content/uploads/2025/07/1-forged-wheels-comparison-3d-render-style-cre.png)

Based on my years in sales and production, I've gained unique insights working with customers, designers, and manufacturing teams. Let me share what I've learned about the eternal debate between one-piece and multi-piece forged wheels, and how you can get the best of both worlds.

What are the disadvantages of multi piece wheels?

Customers often come to me excited about multi-piece designs but don't realize the compromises. The beautiful aesthetics hide structural vulnerabilities that could affect safety and performance during intense driving.

Multi-piece wheels have several disadvantages, including reduced structural integrity from bolt connections, higher maintenance requirements, potential air leakage between sections, increased weight, and higher cost compared to one-piece alternatives.

The most significant drawback of multi-piece wheels is their inherent structural compromise. Think about it - a wheel machined from a single block of aluminum will always be stronger than pieces joined by bolts. Those connection points create potential failure spots under extreme stress. This is why we typically recommend one-piece designs for serious track use or performance applications.

Maintenance also becomes more complex with multi-piece wheels. The bolts require regular inspection and torque checks to maintain proper connection between components. Over time, these connection points can develop air leaks, especially after aggressive driving or hitting potholes. This means more frequent tire pressure checks and potential roadside issues.

Weight is another factor many buyers overlook. Those beautiful bolts and extra components add unsprung weight to your vehicle, potentially reducing acceleration, braking performance, and ride quality. For pure performance, the additional weight rarely justifies the aesthetic benefits.

| Factor | One-Piece Wheel | Multi-Piece Wheel |

|---|---|---|

| Structural Integrity | Higher (no connection points) | Lower (bolt connections) |

| Maintenance | Minimal | Regular bolt checks required |

| Weight | Generally lighter | Typically heavier |

| Cost | Lower manufacturing cost | Higher due to complex assembly |

| Customization | Limited by forge size | Highly customizable designs |

Are 2 piece wheels better than 1 piece?

My customers frequently ask this question, especially when they see stunning 2-piece designs online. They're torn between the proven reliability of one-piece wheels and the customization options of multi-piece designs.

No, 2-piece wheels aren't inherently "better" than 1-piece wheels. They offer greater customization options, replaceable components if damaged, and wider sizing possibilities, but sacrifice some structural strength and add maintenance requirements.

The "better" wheel truly depends on your priorities and how you'll use your vehicle. From my years working with both manufacturers and customers, I've found that 2-piece wheels excel in certain areas while falling short in others. The decision involves understanding this tradeoff.

For pure styling and customization, 2-piece wheels deliver unmatched flexibility. With separate barrel and center sections, you can create unique lip depths, widths, and offsets that simply aren't possible with one-piece forgings. The manufacturing process for 2-piece wheels allows for creative freedom that can transform your vehicle's appearance. Additionally, if you damage just the lip or face, you can replace only that component rather than the entire wheel.

However, one-piece wheels maintain a significant advantage in structural rigidity. When forged from a single piece of aluminum, there are no connection points to potentially fail under stress. This creates a wheel that can handle higher loads, more aggressive driving, and rougher conditions without concern. The manufacturing process also typically results in a lighter wheel than an equivalent 2-piece design.

| Feature | One-Piece Advantage | Two-Piece Advantage |

|---|---|---|

| Strength | Superior (single forging) | Good but has connection points |

| Weight | Generally lighter | Typically slightly heavier |

| Customization | Limited by forge dimensions | Greater style flexibility |

| Repair Options | Must replace entire wheel | Can replace damaged sections |

| Manufacturing Complexity | Simpler process | More complex assembly |

| Cost | Generally lower | Typically higher |

Why is the servicing of multi-piece rim wheels extremely hazardous?

When customers consider multi-piece wheels, they rarely think about maintenance risks. I've seen serious injuries from improper servicing, which makes me emphasize safety whenever discussing these wheels.

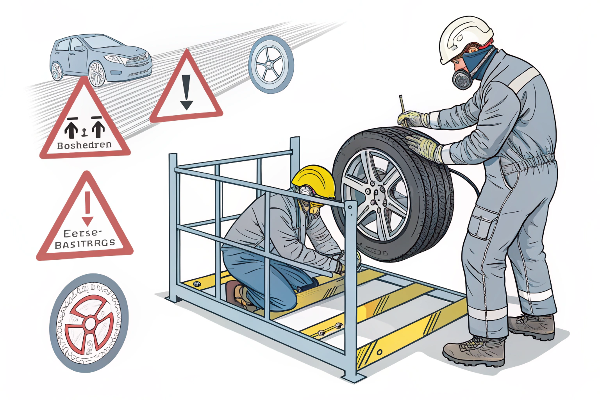

Servicing multi-piece wheels is extremely hazardous because improper assembly can lead to explosive separation under pressure. The bolts that secure wheel components can loosen over time, and trapped pressure between sections can cause components to separate violently during tire changes.

The dangers of working with multi-piece wheels aren't immediately obvious, but they're very real. Throughout my career, I've heard numerous accounts of serious injuries occurring during wheel servicing. The fundamental issue stems from how these wheels are constructed and the pressures involved.

Unlike one-piece wheels, multi-piece designs rely on bolts and seals to maintain their structural integrity. Over time and through normal use, these connection points can develop subtle problems. Bolts may loosen incrementally, corrosion can develop between sections, or seals may degrade—all potentially invisible to the naked eye. When a technician begins working on these wheels, they may not realize the components are under stress.

The most dangerous scenario occurs when a partially loosened wheel still has pressurized air trapped inside. As a technician removes bolts or separates sections, the remaining pressure can cause components to violently separate without warning. These heavy metal parts can become dangerous projectiles, causing serious injuries or even fatalities.

Professional wheel service centers follow strict protocols when working with multi-piece wheels, including complete deflation, proper restraining equipment, and specialized training. However, many smaller shops or DIY enthusiasts may not be aware of or follow these protocols.

| Safety Concern | Risk Level | Prevention Measure |

|---|---|---|

| Explosive Separation | Severe | Complete deflation before servicing |

| Flying Components | High | Use safety cages and restraints |

| Hidden Damage | Moderate | Thorough inspection before servicing |

| Improper Assembly | High | Follow manufacturer torque specifications |

| Corrosion Effects | Moderate | Regular inspection of all mating surfaces |

What is the point of 3 piece wheels?

Car enthusiasts often ask me this question at trade shows. They wonder why anyone would choose more complex 3-piece wheels when simpler options exist. It's a fair question with compelling answers.

Three-piece wheels exist primarily for ultimate customization flexibility. They allow for precise fitment adjustments, unique aesthetic combinations, easier repairs, extreme lip depths, and width options that aren't possible with one-piece designs.

From my experience working with custom wheel manufacturers, I've seen firsthand why 3-piece wheels continue to thrive despite their complexity. The primary appeal centers on unmatched customization possibilities that simply can't be achieved through other construction methods.

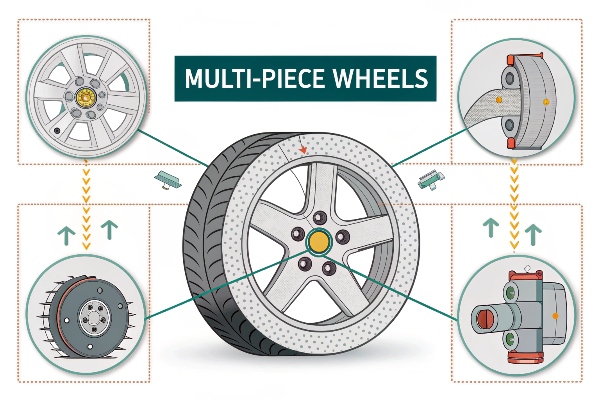

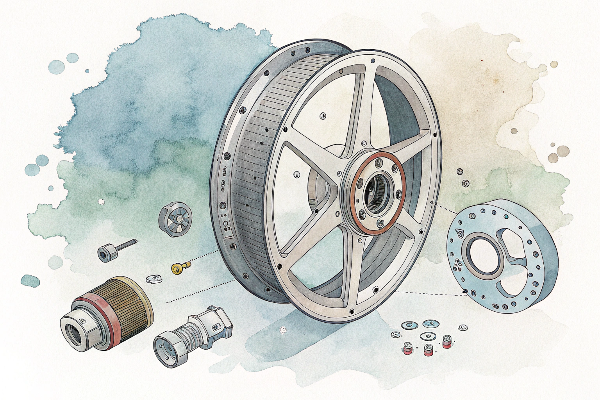

Three-piece wheels consist of an outer lip, an inner barrel, and a center face section—all joined by precision bolts. This modular construction enables virtually unlimited combinations of widths, offsets, concavity, and lip depths. For instance, customers seeking an extremely aggressive deep-lip appearance for show cars can achieve dramatic looks impossible with one-piece forged wheels due to manufacturing constraints.

The customization extends beyond just dimensions. With separate components, builders can mix materials and finishes—perhaps a polished lip with a brushed face and custom-colored hardware—creating truly one-of-a-kind wheels. This level of personalization appeals strongly to enthusiasts wanting their vehicles to stand apart.

Beyond aesthetics, 3-piece wheels offer practical advantages. If you damage just one section—say, scraping a lip against a curb—you can replace only that component rather than the entire wheel. This modular approach can actually save money in the long term despite the higher initial investment.

For specialty applications requiring extreme fitment precision, 3-piece wheels allow for micro-adjustments by substituting different width lips or barrels. This adaptability makes them particularly valuable for heavily modified vehicles with unconventional suspension setups or fender modifications.

| Feature | Benefit of 3-Piece Construction |

|---|---|

| Component Customization | Mix materials, finishes and colors |

| Repair Flexibility | Replace only damaged sections |

| Fitment Precision | Fine-tune width and offset exactly |

| Aesthetic Options | Achieve extreme lip depths and styles |

| Future Modification | Change specs without buying new wheels |

| Specialty Fitments | Accommodate rare or custom applications |

Conclusion

One-piece wheels offer superior strength and simplicity, while multi-piece designs prioritize customization and unique aesthetics. For the best of both worlds, consider hidden bolt three-piece wheels for a seamless look with modular benefits. TreeWheels delivers custom forged excellence with sincerity above all, ensuring your perfect wheel solution.