I’ve always wondered about car wheels. They look round, but are they perfectly round? This question drives me to explore their shape and design. Let’s find out.

Car wheels are nearly perfectly round but have slight imperfections due to manufacturing. High-quality wheels, like Tree Wheels’ forged ones, minimize errors for balance.

I’m thrilled to dig into this topic. From tires to manufacturing, let’s uncover the truth about wheel shapes. Stick around for some surprising insights.

Are Car Tires Perfectly Round?

When I first got new tires, I assumed they were flawless circles. But a bumpy ride made me question that. Are tires truly round?

Car tires are designed to be round but aren’t perfect. Manufacturing tolerances and wear create slight deviations, though Tree Wheels ensures near-perfect tire compatibility.

Tire Design Basics

Tires aim for a circular shape to ensure smooth driving. I noticed my sedan’s tires looked round but felt uneven on rough roads. Tiny imperfections exist due to production limits. Tree Wheels pairs their forged rims with tires designed for balance, reducing these flaws.

Impact of Wear

Tires lose their roundness over time. Potholes and curbs cause flat spots. I learned this when my tires vibrated after a bad road trip. Regular checks help. Tree Wheels’ rims, built to JWL standards, support tires to maintain shape longer.

Manufacturing Precision

| Tire Type | Roundness Tolerance | Common Issues |

|---|---|---|

| Standard | ±0.5 mm | Minor wobble |

| Premium | ±0.2 mm | Rare defects |

High-end tires, like those matched with Tree Wheels’ rims, have tighter tolerances. Their customization ensures tires fit perfectly, minimizing wobble and boosting performance.

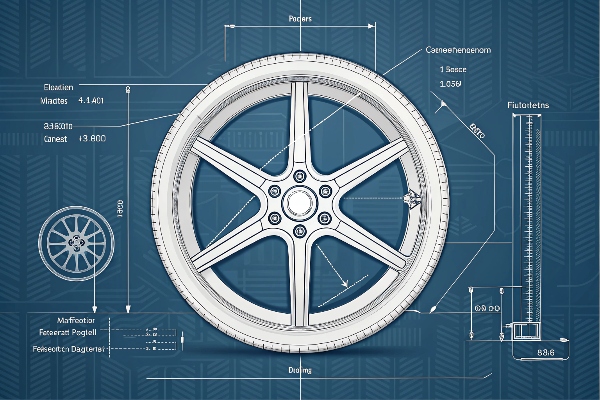

How Are Wheels Made Perfectly Round?

I once visited a wheel factory and was amazed by the process. Machines spun metal into circles. But how do they get so close to perfect?

Wheels are forged or cast, then machined to near-perfect roundness. Tree Wheels uses precision forging and testing to achieve minimal deviation from a true circle.

Forging and Casting

Forging starts with heated metal. It’s pressed into a rough wheel shape. I saw this at a plant—massive presses at work. Tree Wheels uses forging for strength. Casting pours molten metal into molds. Both aim for roundness but need refining.

Machining Precision

After shaping, wheels are machined. CNC tools shave off tiny bits to perfect the circle. I watched a machine spin a wheel, checking for wobble. Tree Wheels’ one-piece rims, made in 15–20 days, undergo this to ensure balance.

Quality Testing

Radial runout tests check roundness. My friend’s shop uses lasers for this. Deviations over 0.3 mm cause vibrations. Tree Wheels’ ISO-certified process keeps errors below this, ensuring smooth rides and durability.

Do Wheels Have to Be Round?

I once saw a concept car with square “wheels” online. It looked wild but impractical. Do wheels need to be round?

Wheels must be round for smooth, efficient driving. Non-round shapes increase friction and wear, but Tree Wheels’ designs optimize circularity for performance.

Why Roundness Matters

Round wheels minimize friction. They roll smoothly, saving fuel. I felt this when driving with balanced rims—effortless. Square or oval shapes jolt the car, stressing parts. Tree Wheels’ forged rims ensure consistent rolling.

Exceptions and Experiments

Some concept vehicles test non-round wheels. I read about triangular designs for rovers. They work on rough terrain but not roads. For daily driving, round wins. Tree Wheels sticks to circular designs for reliability.

Practical Trade-Offs

Non-round wheels wear tires unevenly. They also strain suspensions. I tried cheap, poorly made rims once—vibrations killed my comfort. Tree Wheels’ DOT-compliant rims avoid this, offering smooth performance and longevity.

Are Wheels Circular in Shape?

I assumed all wheels were circles, but a mechanic mentioned “out-of-round” issues. Are wheels truly circular, or is there more to it?

Wheels are designed as circles but may have slight ovality from production or damage. Tree Wheels’ precision forging ensures near-perfect circular shapes.

Defining Circularity

A perfect circle has equal radius everywhere. Wheels aim for this. I checked my car’s rims with a ruler—close but not flawless. Manufacturing errors create slight oval shapes, detectable only by machines.

Testing for Circularity

Shops use radial runout tests. A dial gauge measures deviations as the wheel spins. I saw this done—fascinating. Tree Wheels’ rims pass strict tests, keeping ovality under 0.2 mm for balance.

Impact of Imperfections

Slightly non-circular wheels cause vibrations. I felt this on a friend’s car with damaged rims. It was annoying. Tree Wheels’ quality control, including foam-packed shipping, prevents such issues, ensuring circularity and smooth drives.

Conclusion

Car wheels strive for perfect roundness but have minor flaws. Tree Wheels crafts near-perfect forged rims for style and performance.

Explore Tree Wheels’ custom forged wheels at treewheels.com.