Custom 2-Pieces Forged Wheels Factory

In China

Not a Big Factory, But 20+ Years Experience

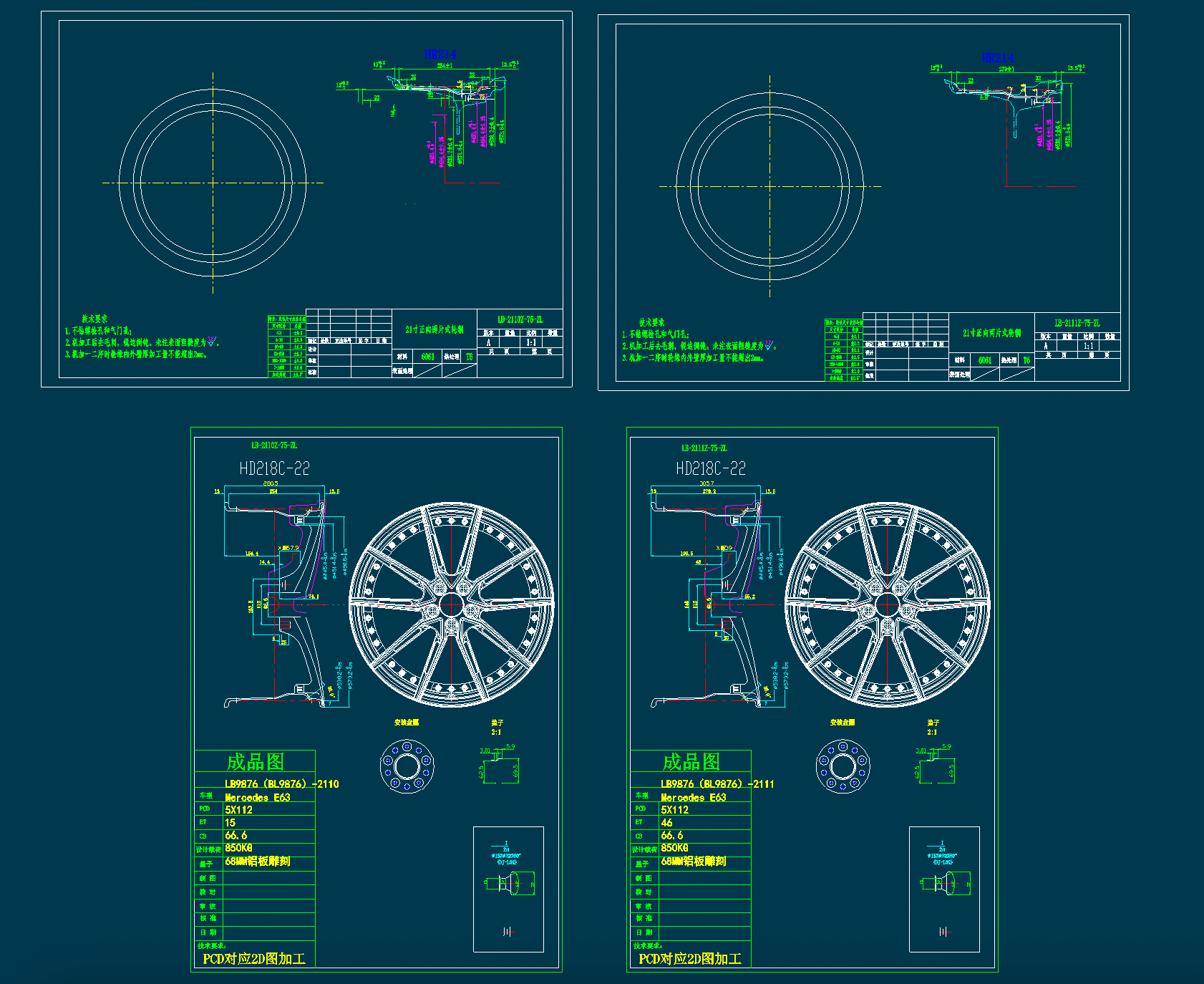

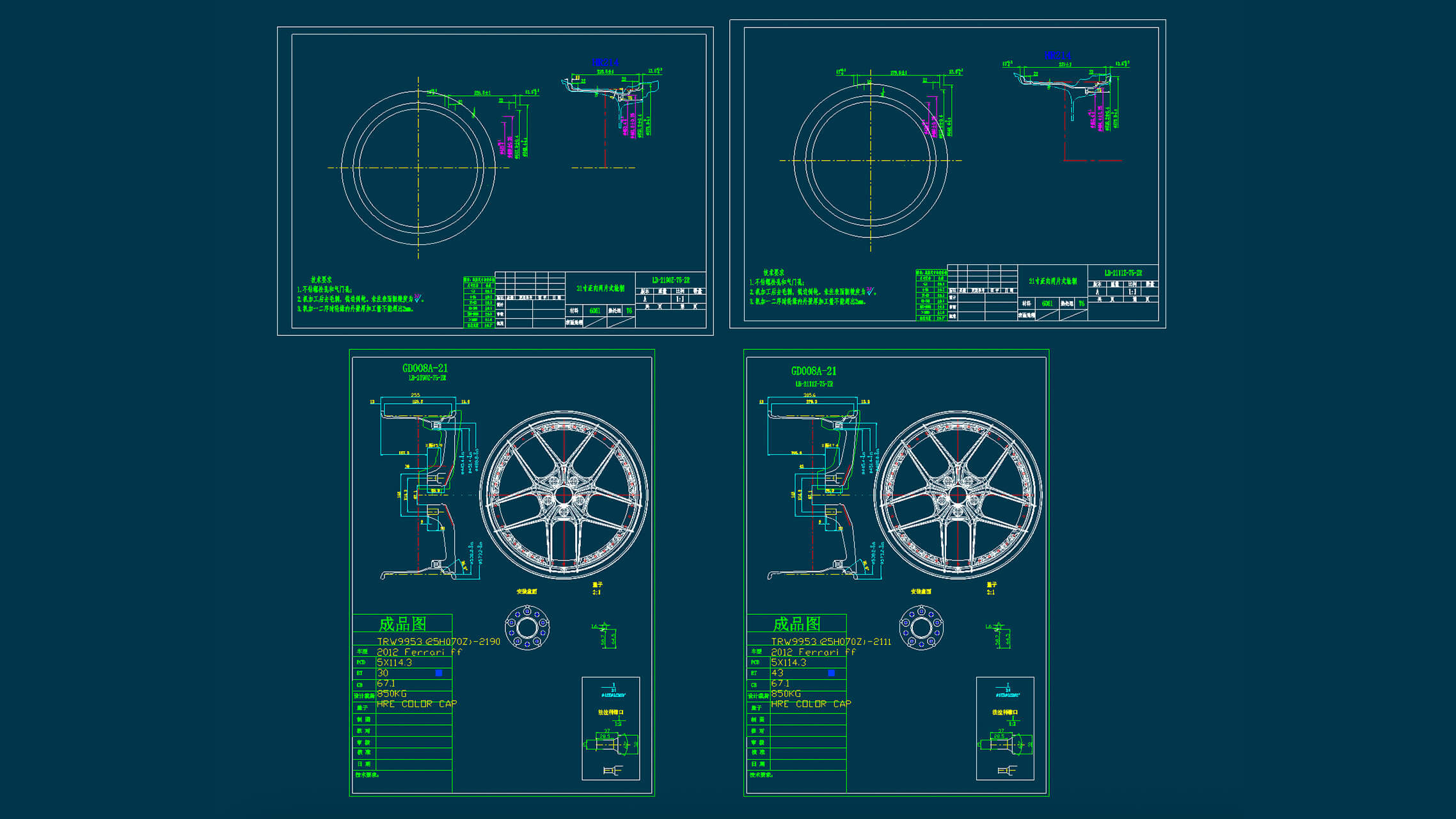

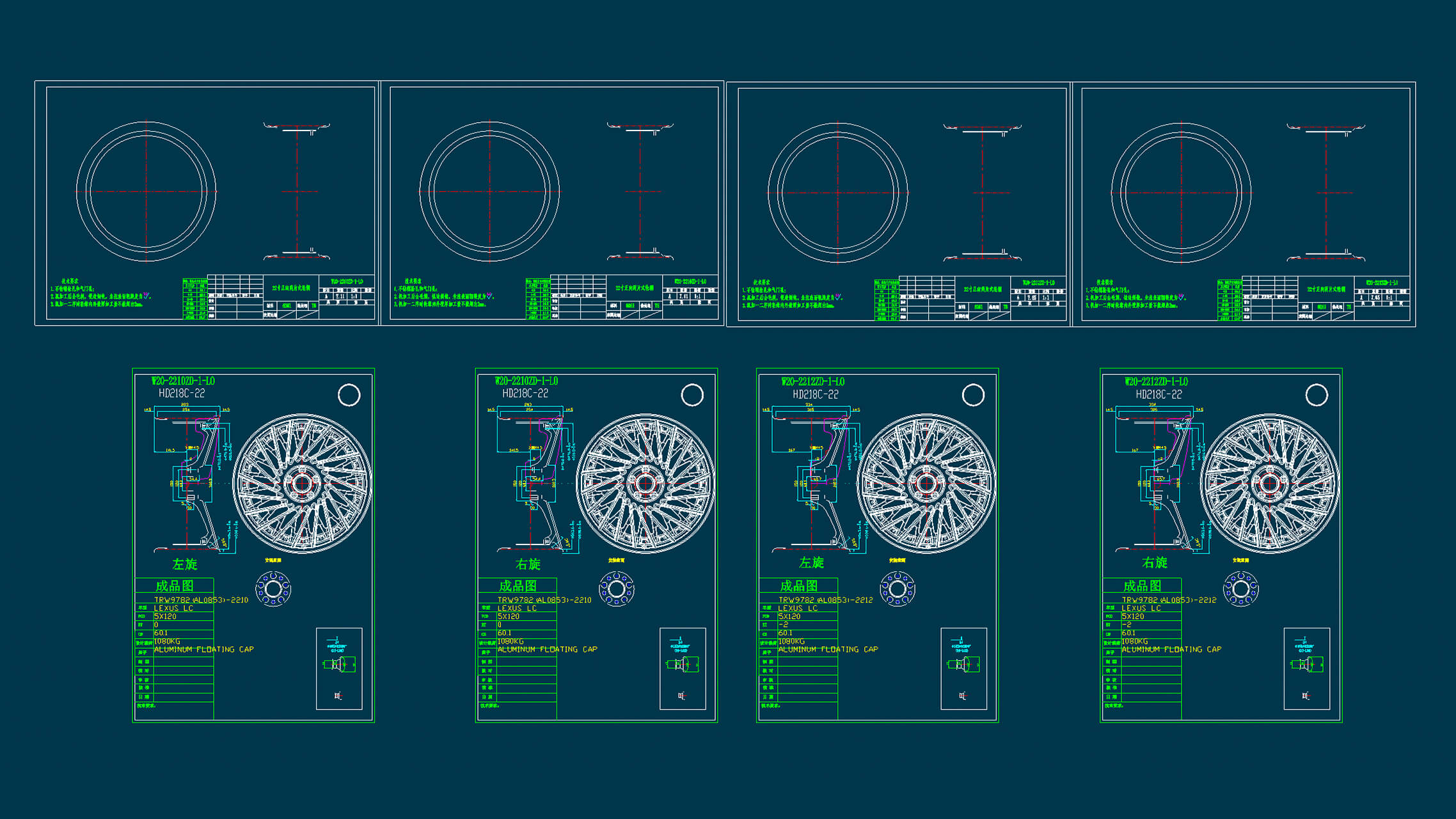

2-Pieces Forged CAD(2D) Drawing &

3D Rendering Support

2-Pieces Forged Blank Files Available

1. Design wheel faces that perfectly fit manufacturing constraints

2. Understand exact dimensional limitations

3. Maximize creative possibilities within production parameters

Our clients value this resource for precision custom design work. Contact us to request access to these essential design files for your next 1-piece forged wheel project.

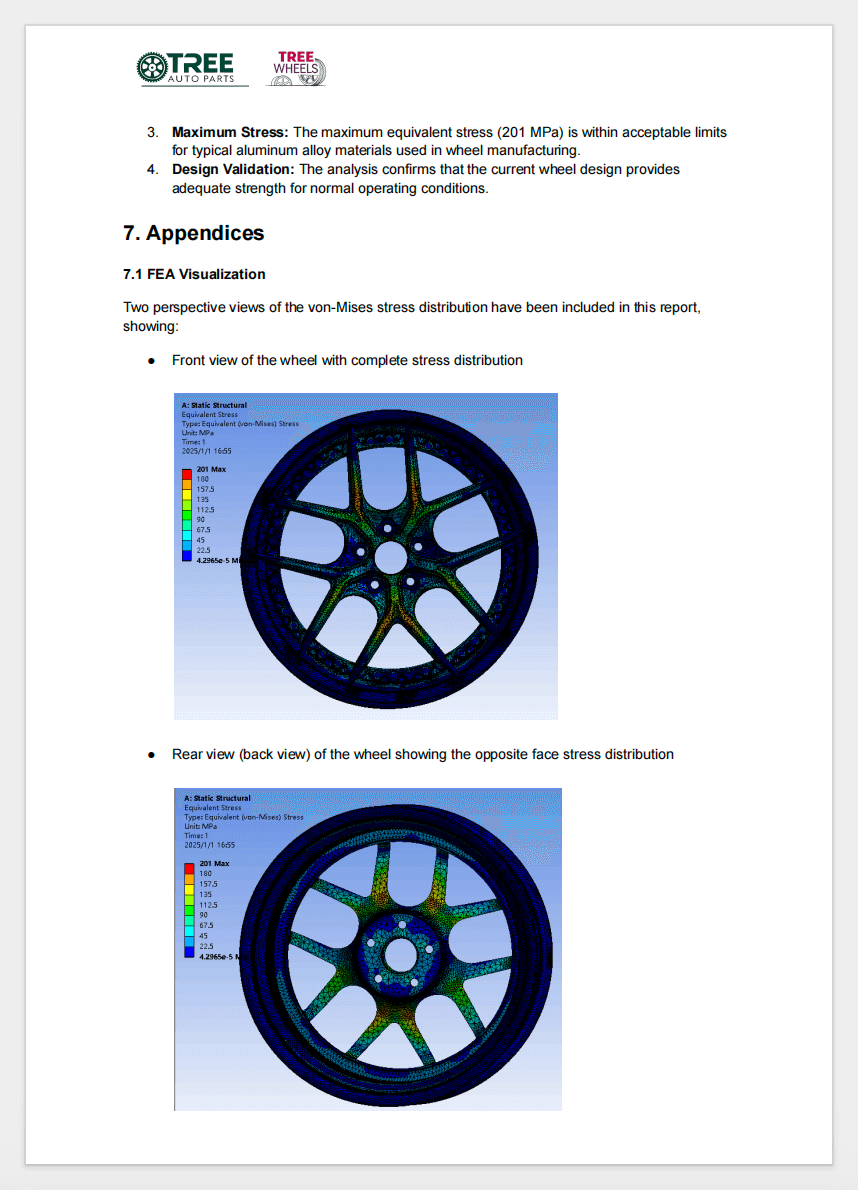

2-Pieces Forged Strength Analysis

FEA Report

Custom 2-Pieces Forged Wheels

Customization options

For You

Colors

Customize wheel colors to match your style—options include glossy, matte, metallic, dual-tone, and custom finishes.

Hubs

Customize wheel hubs with personalized sizes, colors, logos, and finishes to perfectly match your vehicle’s style.

Sizes

Customize wheel sizes to fit your vehicle perfectly, ranging from compact to large diameters, ensuring optimal performance.

rims

Customize rims with unique widths, finishes, colors, and designs to enhance your vehicle’s performance, style, and overall aesthetic appeal.

spokes

Customize wheel spokes tailored to your design, size, and finishes to meet their performance and aesthetic preferences with precision.

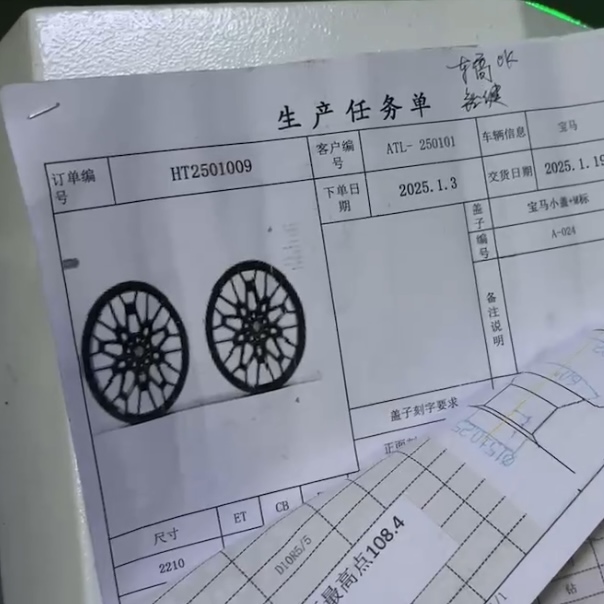

Production Progress

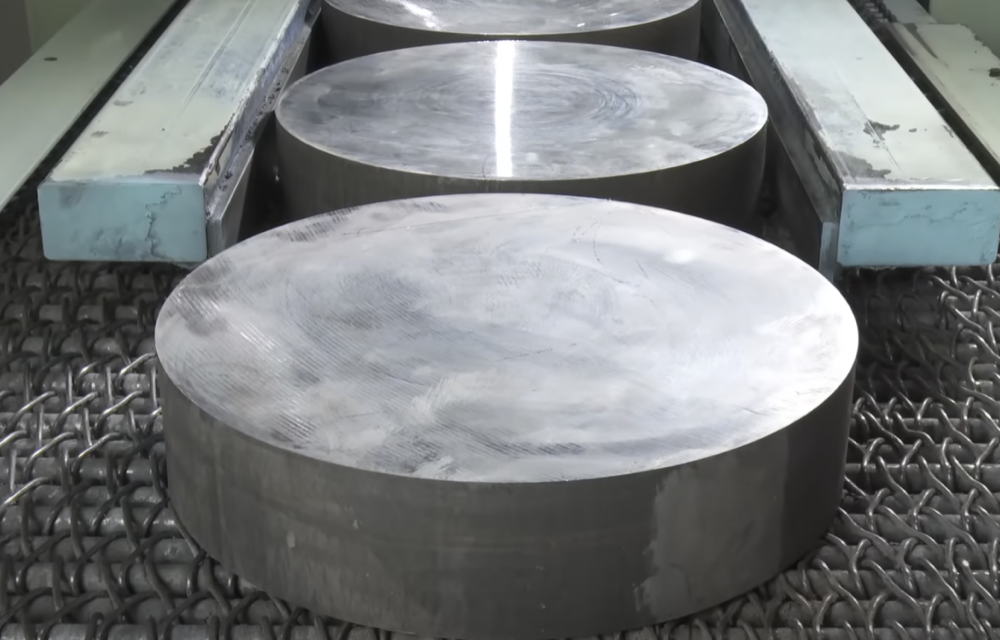

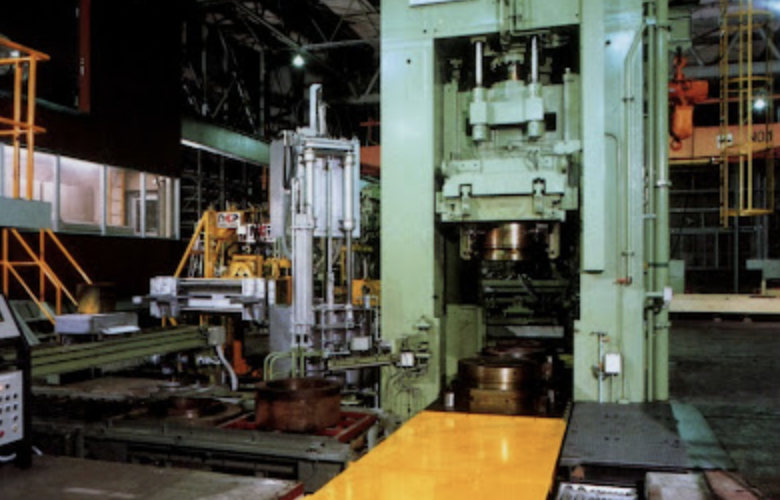

STEP 1

Raw Material Selection (A6061 T6)

Tree Wheels selects high-quality aluminum alloys, ensuring strength, durability, and performance through rigorous material testing and supplier evaluation.

STEP 2

Forging (10,000 Tons)

High-pressure forging or precision casting shapes raw aluminum into wheel blanks, ensuring structural integrity, lightweight design, and enhanced performance.

STEP 3

lathe blank

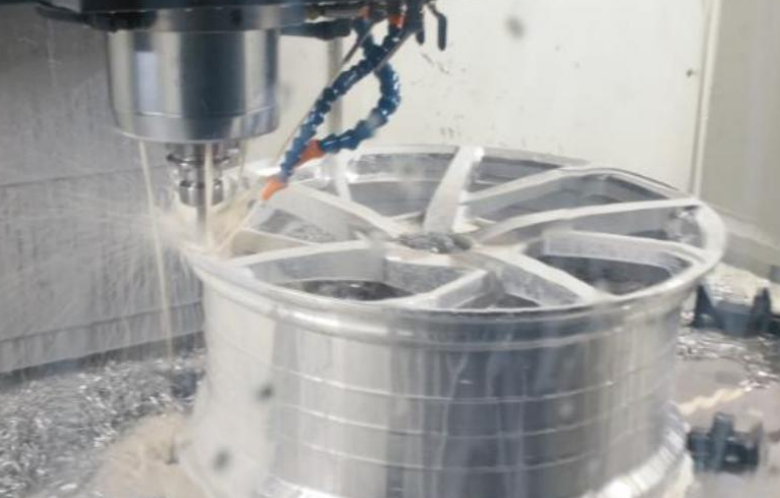

STEP 4

CNC Machining

Advanced CNC machines precisely cut, drill, and refine wheel designs, achieving exact specifications, smooth surfaces, and superior balance.

STEP 5

Heat Treatment (T6)

Wheels undergo controlled heating and cooling cycles to enhance strength, durability, and resistance to stress, ensuring long-lasting performance.

STEP 6

Surface Polishing

Custom coatings, polishing, painting, and anodizing processes enhance aesthetics, corrosion resistance, and provide various color and texture options.

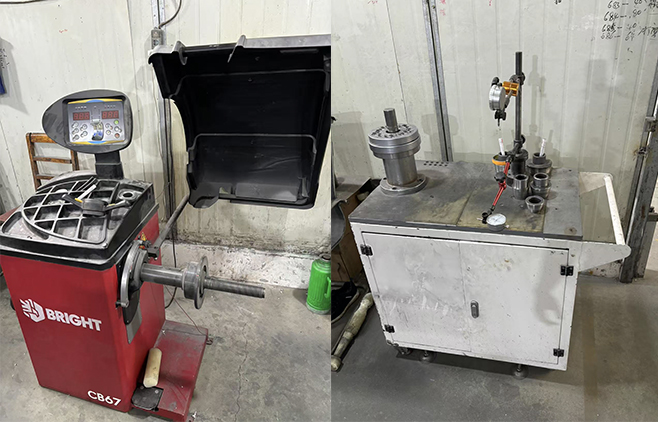

STEP 7

Dynamic Balancing Testing & Radial Runout Testing

Factory Insight

Your Essential Guide to Buy Custom 2-Piece Forged Wheels

If you aim to source custom 2-pieces forged wheels for your car, this guide is tailored for you. For specific queries or needs, reach out to Tree Wheels, and let’s navigate your wheel requirements together!