2-Piece FORGED WHEELS

Custom 2-Piece Forged Wheels

Customization options

For You

Colors

Customize wheel colors to match your style—options include glossy, matte, metallic, dual-tone, and custom finishes.

Hubs

Customize wheel hubs with personalized sizes, colors, logos, and finishes to perfectly match your vehicle’s style.

Sizes

Customize wheel sizes to fit your vehicle perfectly, ranging from compact to large diameters, ensuring optimal performance.

rims

Customize rims with unique widths, finishes, colors, and designs to enhance your vehicle’s performance, style, and overall aesthetic appeal.

spokes

Customize wheel spokes tailored to your design, size, and finishes to meet their performance and aesthetic preferences with precision.

Production Progress

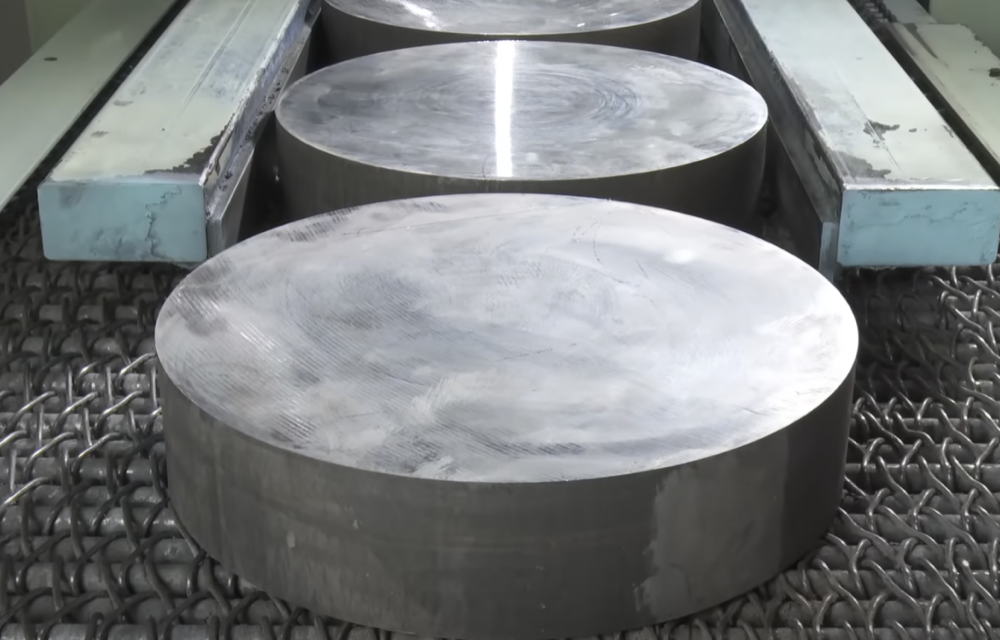

STEP 1

Raw Material Selection (A6061 T6)

Tree Wheels selects high-quality aluminum alloys, ensuring strength, durability, and performance through rigorous material testing and supplier evaluation.

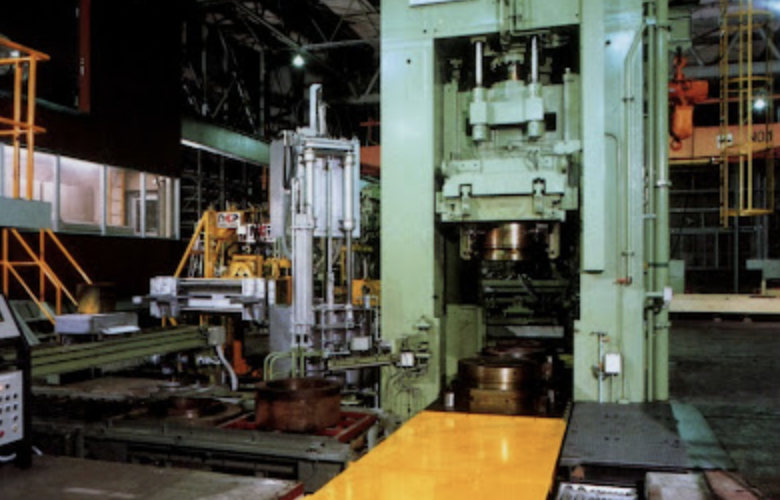

STEP 2

Forging (10,000 Tons)

High-pressure forging or precision casting shapes raw aluminum into wheel blanks, ensuring structural integrity, lightweight design, and enhanced performance.

STEP 3

Heat Treatment (T6)

Wheels undergo controlled heating and cooling cycles to enhance strength, durability, and resistance to stress, ensuring long-lasting performance.

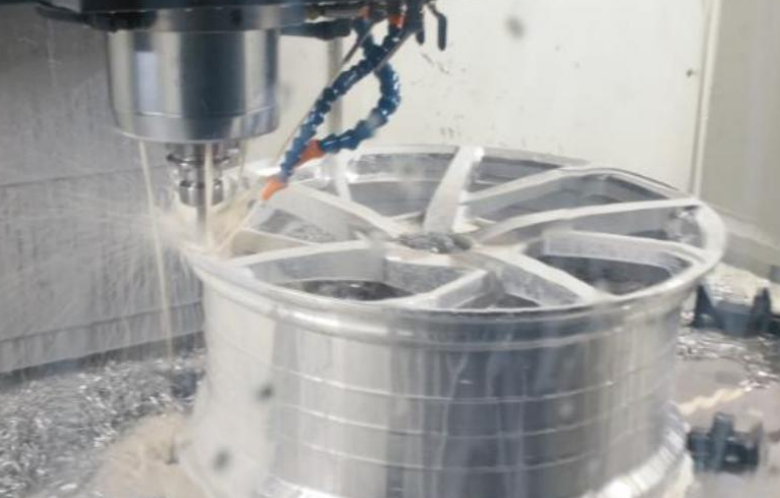

STEP 4

CNC Machining

Advanced CNC machines precisely cut, drill, and refine wheel designs, achieving exact specifications, smooth surfaces, and superior balance.

STEP 5

Surface Finishing

Custom coatings, polishing, painting, and anodizing processes enhance aesthetics, corrosion resistance, and provide various color and texture options.

STEP 6

Quality Inspection

Each wheel undergoes rigorous ISO & DOT-certified testing, including strength, balance, and durability checks to meet international safety standards.

STEP 7

Packaging

Wheels are securely packaged with foam padding and 7-layer corrugated boxes, ensuring protection during transportation and safe delivery.

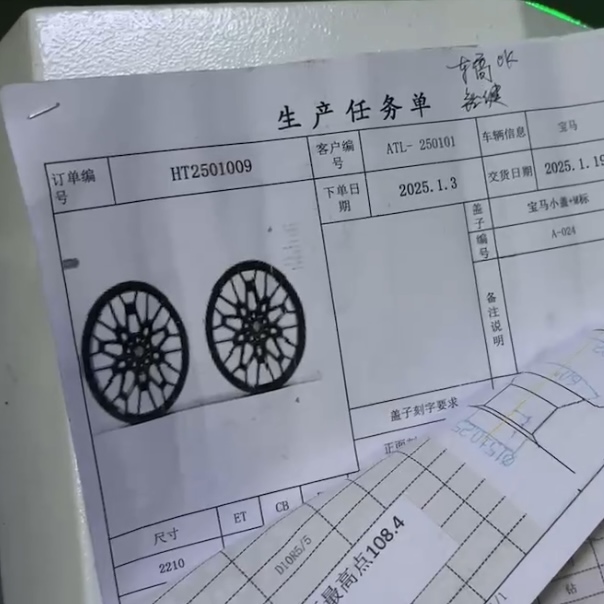

Factory Insight

Your Essential Guide to Buy Custom 2-Piece Forged Wheels

If you aim to source custom 2-piece forged wheels for your car, this guide is tailored for you. For specific queries or needs, reach out to Tree Wheels, and let’s navigate your wheel requirements together!

Table of Contents

What are 2-piece forged wheels?

What advantages do 2-piece forged wheels have over cast wheels?

How customizable are 2-piece forged wheels?

Are 2-piece forged wheels worth the investment?

For performance-driven buyers, they’re a solid investment. Forging ensures lightweight durability, enhancing handling and reducing suspension wear. Their modular design simplifies repairs, like replacing a damaged rim. Priced between $1500-$2500 each, their long-term performance, safety, and resale value justify the cost—a premium choice for serious enthusiasts.

How do 2-piece forged wheels compare to 3-piece wheels?

How long does it take to deliver custom 2-piece forged wheels?

How durable are 2-piece forged wheels in extreme conditions?

Forged wheels excel in harsh environments like racing or off-roading. Their dense structure resists cracking, while features like knurled beads enhance stability under torque. Many exceed standard tests, handling high loads and impacts reliably, making them a robust choice for demanding applications.

Will 2-piece forged wheels fit my vehicle’s brake system?

Yes, most manufacturers offer tailored machining to match brake systems, including aftermarket setups. By providing your vehicle and brake specs, wheels can be crafted with precise center bores and bolt patterns for a perfect fit. Always confirm compatibility with your supplier for a smooth install.

What certifications should I look for in 2-piece forged wheels?

How much do 2-piece forged wheels cost?

In Summary

Get In Touch

Sample Available